Copper tubing remains the gold standard in plumbing, refrigeration, and HVAC systems worldwide due to its durability, reliability, and versatility. Understanding the differences between soft and hard copper tubing, their applications, and proper installation techniques is essential for both professionals and ambitious DIYers.

Advanced Soldering Techniques for Hard Copper Tubing Installations

Hard copper tubing requires precise soldering techniques to ensure leak-free joints. When working with hard copper, proper preparation is critical—clean the pipe ends with emery cloth until shiny, apply flux evenly, and heat the joint uniformly until the solder flows freely through capillary action. For professional results, use a neutral flame and heat the fitting, not the solder. The completed joint should show a visible solder line around the entire circumference.

The Cost-Benefit Analysis: Soft vs. Hard Copper Tubing for Residential Projects

While soft copper typically costs 15-20% more than rigid copper, the labor savings can be substantial. Soft copper requires fewer fittings and joints, reducing potential leak points and installation time. For residential projects with many bends and turns, soft copper’s flexibility offers significant advantages. Hard copper, however, provides better structural integrity for exposed installations and straight runs. The decision ultimately depends on the specific application, accessibility, and budget constraints.

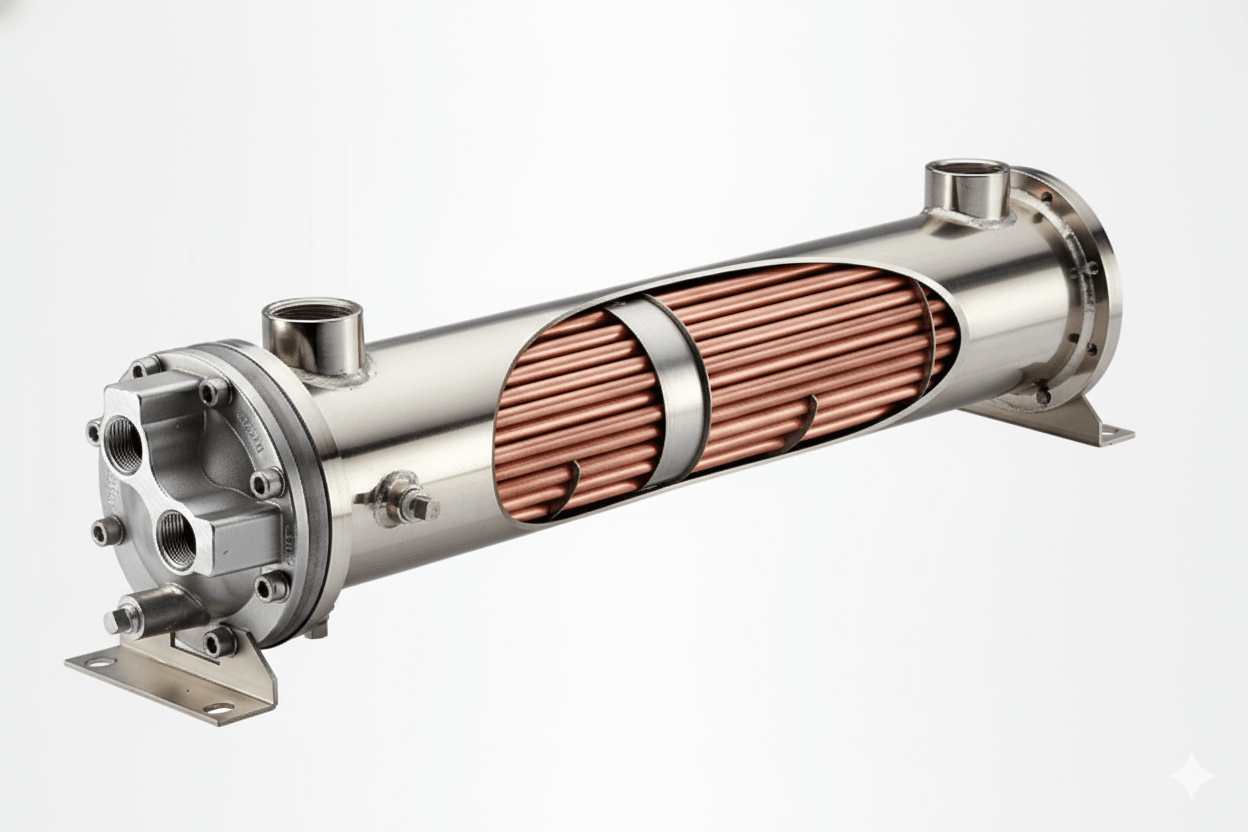

Copper tubing comes in three primary grades with varying wall thicknesses. Type K (thickest) is ideal for underground installations, high-pressure systems, and service lines. Type L (medium thickness) is the standard for most interior residential and commercial plumbing. Type M (thinnest) is suitable for low-pressure applications like drain lines or heating systems. Always consult local building codes, as some jurisdictions restrict certain grades for specific applications.

Converting Hard to Soft Copper: Expert Annealing Techniques for Field Applications

When faced with limited material options, professionals can anneal hard copper to increase flexibility. Heat the copper evenly with a propane torch until it glows dull red, then allow it to cool naturally. Once annealed, the copper becomes more malleable, allowing for bending without crimping. This technique is particularly valuable for retrofit work where space is limited, though the process does reduce the tubing’s tensile strength.

Corrosion Resistance Comparison: How Soft and Hard Copper Perform in Various Environments

Both soft and hard copper offer excellent corrosion resistance in most environments. However, water quality significantly impacts longevity. High-velocity water flow (exceeding 8 feet per second) can cause erosion-corrosion, particularly at elbows and bends. Hard copper’s greater rigidity can sometimes better withstand aggressive water conditions. In areas with highly acidic water (pH below 6.5), consider protective coatings or alternative materials for extended service life.

For DIY installations, essential tools include a tubing cutter, deburring tool, flux brush, propane torch, and appropriate fittings. When bending soft copper, use a spring bender to prevent kinking—place the spring over the tubing and bend gradually to the desired angle. For joining, soldering (sweating) remains the most reliable method, though push-fit and compression fittings offer solderless alternatives for novices working in accessible locations.

Meeting Building Codes: Copper Tubing Selection for Residential and Commercial Plumbing

Building codes typically specify minimum requirements for tubing material, wall thickness, and installation methods. Commercial applications generally require heavier gauge tubing (Types K or L) than residential projects. Many jurisdictions prohibit Type M for potable water supply or have restrictions based on water quality parameters. Always verify current local codes before beginning any installation project.

Comparing Connection Methods: Flare, Compression, and Soldered Fittings for Copper Tubing

Soldered connections offer the strongest, most permanent joints but require heat application. Compression fittings provide reliable mechanical connections without soldering, ideal for locations where flames pose hazards. Flare fittings excel in high-pressure applications, particularly in refrigeration and fuel systems. Each method has distinct advantages—selection depends on the application, accessibility, and whether future disassembly might be necessary.

By understanding these fundamental aspects of copper tubing selection and installation, professionals and homeowners alike can ensure safe, efficient, and code-compliant systems that will provide decades of reliable service.