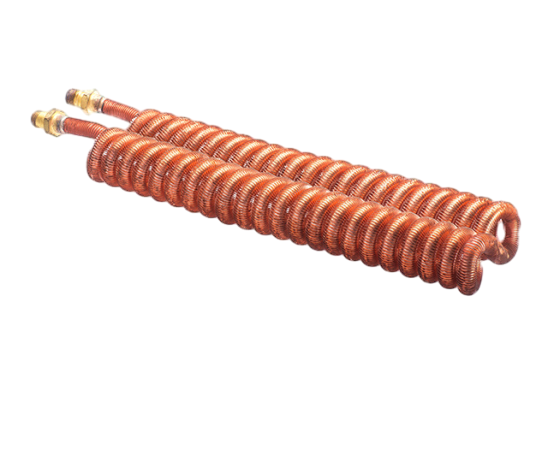

Finned Coil

Finned coils, "U" bends and serpentine shapes increase heat transfer efficiency and save space for your custom heat exchangers.

Custom Copper Finned Tube Coil

With full of spiral finned coil manufacturing experiences, Cufin Tube’s spiral finned coils and finned cooling coils offer very high heat transfer efficiency by high surface area-to-volume ratio, such compact design helps smaller the size and save assembling space, as well as reduce labor cost. Our coils and bending are perfect for your custom heat exchanger designs.

About Cufin Cooling Coils

Designed for max efficiency and performance

Finned coils, or finned tube coils, are specialized heat exchangers designed to enhance heat transfer efficiency in various applications. They consist of tubes with fins attached to their outer surfaces, which increase the effective surface area for heat exchange between a fluid inside the tube and the surrounding environment.

Compact Design: Finned coils are designed to provide a high surface area for heat transfer within a limited space, making them ideal for applications where space is at a premium. This compactness is beneficial in both industrial settings and HVAC systems.

Materials: Our finned cooling coils are available in various materials such as carbon steel, stainless steel, copper, aluminum, and other alloys.

Advantages of Cufin's Finned Coils

Improved Efficiency: By maximizing the surface area for heat exchange, finned coils enhance overall system efficiency.

Temperature Control: They allow precise temperature regulation in various systems, contributing to better performance in heating and cooling applications.

Maintenance: Regular cleaning is necessary to maintain efficiency, as dirt accumulation can hinder performance. Coils are easier to clean and maintain since they have no sharp corners or edges.

Storage: Easier to stock after surface treatment.

Material: Resistance to both vibration and corrosion. Copper is also a hygienic and antimicrobial material using in drinking water systems.

Applications of Finned Coils

Our finned coils are utilized in a wide range of applications, including:

1, HVAC Systems: Commonly found in air conditioning units, heat pumps, and ventilation systems.

2, Refrigeration Systems: Used in evaporators and condensers to facilitate cooling processes.

3, Industrial Processes: Essential in sectors like oil refining, chemical processing, and food manufacturing where efficient heat transfer is crucial

4, Chemical and Automotive engineering: Used in oil coolers, mine coolers, air coolers for diesel engines, gas coolers and heater, cooling tower.

5, Nuclear engineering: Uranium enrichment plants.

Finned Coils Production Process

1, Prepare raw material, for some copper tubes, we produce by ourselves, some not regular used, we will order from outside.

2, Inspection the raw materials.

3, Roll forming, extruding or finning process.

4, Leaking pressure test after extruding.

5, Cut into required length.

6, Making plain ends, de-fin, bending and coiling, welding connectors if required.

7, Use special copper washing chemical to wash and clean.

8, Drying.

9, Inspection one by one, surface and specification etc.

10, Packaging. Before delivery, we will do the final inspection and issue the formal QC report.

Why Choose Cufin Tube Finned Coil?

As a spiral finned coils manufacturer, Cufin Tube could offer various kinds of heat transfer coils and spiral heat exchangers with highest quality. With more than 100+ advanced automatic machines, each finned tubing’s accuracy and reliability is guaranteed.

We invest on R&D every year , cooperating with China top universities, employing top fin tube experts, to keep updating and improving our technology on copper finned tubing.

Keywords about Cufin Tube:

- Focusing on finned tubes

- Trust-worthy

- 40+ Years' manufacturing

- Strong R&D

- Reliable Business Partner

- Professional

- Fin tubes exporter

- Absolute competitive

Book A Video Call

Your reliable finned tube coil supplier in China

Mass Production Photos

Check how we will produce your finned tube bulk orders in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your factory or warehouse are 100% qualified.

Frequently Asked Questions

About custom finned coils for heat exchangers

What is a finned coil?

A finned coil is a heat exchanger component designed to improve heat transfer efficiency. It’s usually U bent or serpentine shaped with external fins to increase the surface area for better thermal conductivity.

Can finned coils be customized?

Yes, finned coils can be customized in terms of size, material, fin density (fins per inch), and tube diameter to suit specific applications and performance requirements.

What are the advantages of using finned coils?

Finned coils offer improved heat transfer efficiency, compact design, durability, and versatility across various heating and cooling systems.

Are finned coils suitable for both heating and cooling?

Absolutely. Finned coils are versatile and can handle both heating (e.g., hot water or steam systems) and cooling (e.g., chilled water or refrigerant systems) applications.

What factors should I consider when choosing a finned coil?

How do I maintain a finned coil?

Regular cleaning to remove dust, dirt, or scale buildup is essential for maintaining efficiency. Inspecting for corrosion or mechanical damage can also prolong the coil’s lifespan.

How do finned coils improve heat transfer?

The fins increase the surface area in contact with air or fluid, enhancing heat exchange between the coil and its surrounding medium, leading to higher efficiency.

Do finned coils comply with international standards?

Yes, we design finned coils to meet international standards such as ASME or EN, ensuring high-quality performance and safety.

What industries use finned coils?

Finned coils are widely used in HVAC systems, refrigeration, power plants, petrochemical processing, and industrial heating and cooling applications.

What materials are finned coils typically made of?

Finned coils are commonly made of copper or copper tubes with aluminum fins, but other materials like stainless steel or carbon steel can be used depending on the application and environment.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!