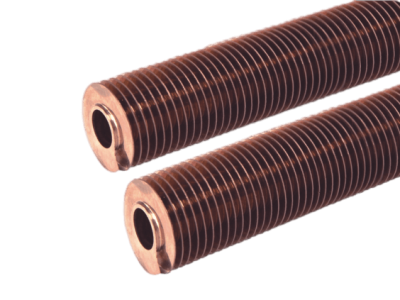

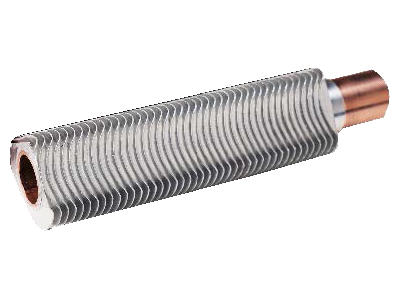

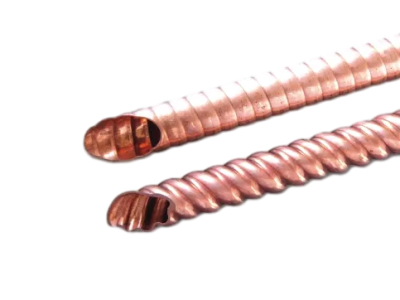

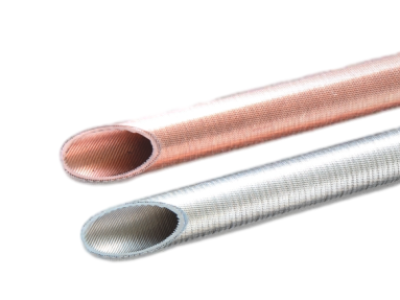

Copper Finned Tubes Manufacturer In China

As an expert manufacturer, Cufintube offers high quality custom finned tube solutions to enhance your heat exchange efficiency.

Get Factory Price Start From 200pcs!

Larger Capacity, Better Price.

Lower MOQ, More Flexibility.

Certified, Safety Guaranteed.

What Set Us Apart

High Efficiency Start From Inquiry

STEP 1

Confirm your requirements

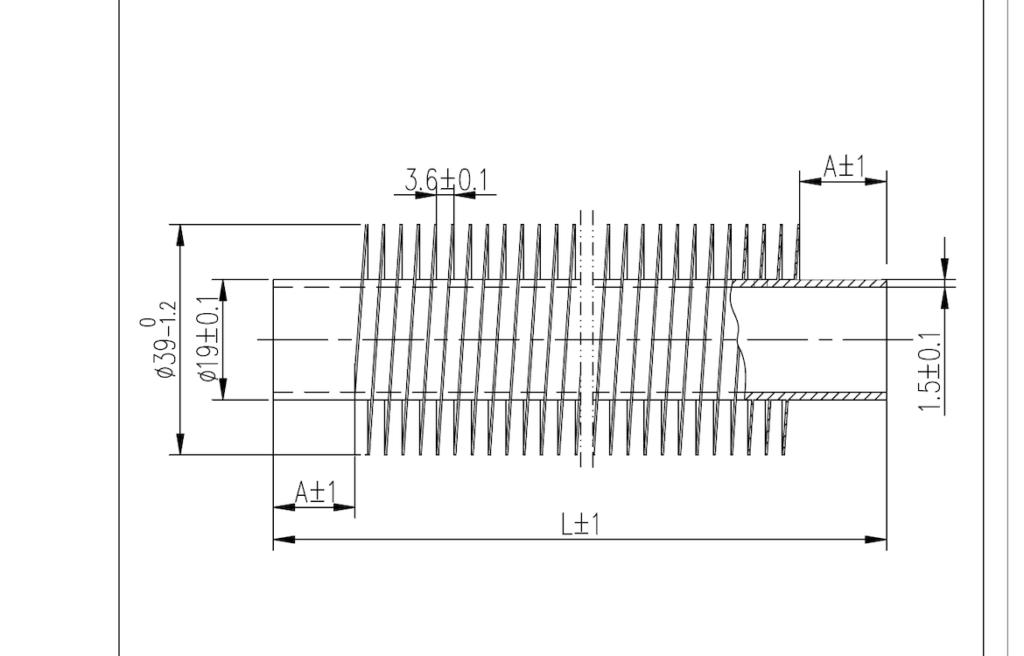

Drawing together with specification and specific materials description provided would greatly improve the whole efficiency.

STEP 2

Confirm price and the drawing

After price confirmed, we will double confirm of the drawing, to avoid mistake. And the delivery and payment terms.

STEP 3

Make deposit payment to fix price

As the raw materials cost prices fluctuate a lot, PI price valid date normally is only one day, or fix final price when deposit arrive, so arrange quick deposit as final confirm.

STEP 4

We handles all the rest including shipment

Strict production plus on line inspection and final sampling inspection with report issued, then we will arrange container loading and shipment.

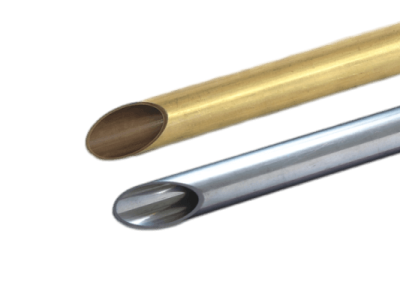

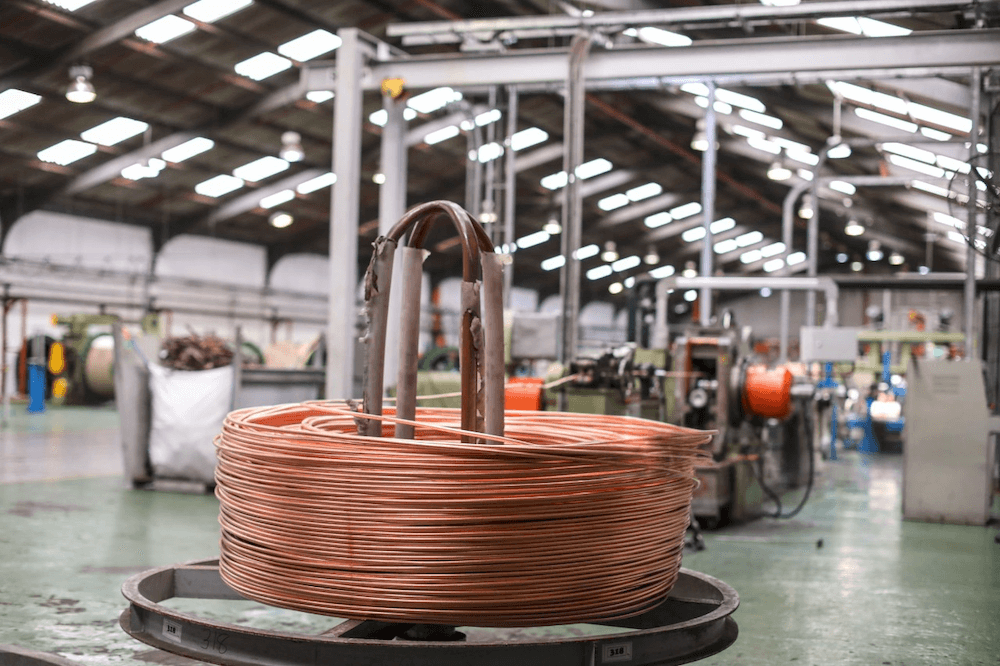

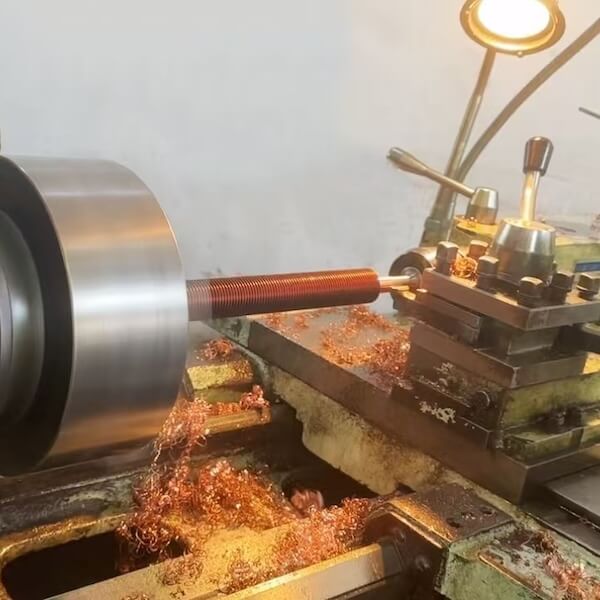

Finned Tubes Manufacturing Process

After your order is confirmed, we first prepare the raw copper tubes, which are then extruded. Before cutting the tubes to the specified length, an intermediate step is conducted — leak testing by 2 MPA Pressure. Then cut to length. Following this, the tubes undergo smooth section turning and cleaning, after which they are dried to remove water.

Primary Industries & Applications

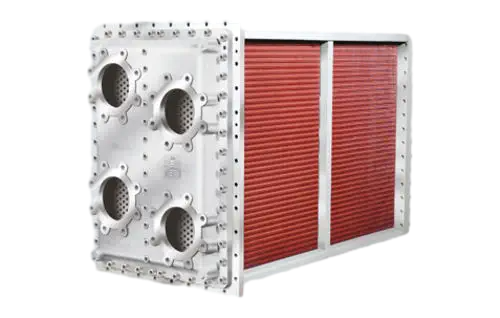

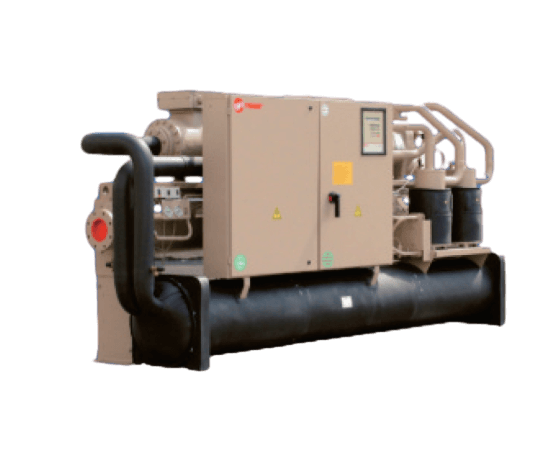

Fin Tubes Used In HVAC & Cooling Systems

Finned tubes are crucial in HVAC and cooling systems, enhancing heat transfer efficiency. They increase the surface area available for heat exchange, allowing for effective heating and cooling of air. Commonly used in air conditioning units and refrigeration systems, finned tubes facilitate rapid temperature control, improving overall system performance and energy savings. Their design enables efficient handling of large air volumes in confined spaces, making them ideal for various industrial applications.

Finned Tubes Used In Gas-Fired Boilers

Finned Tubes Used In Cooling Towers

Finned Tubes Used For Oil & Gas Suppliers

Finned Tubes Used In Mining Equipments

Finned Tubes Used In Water Heater

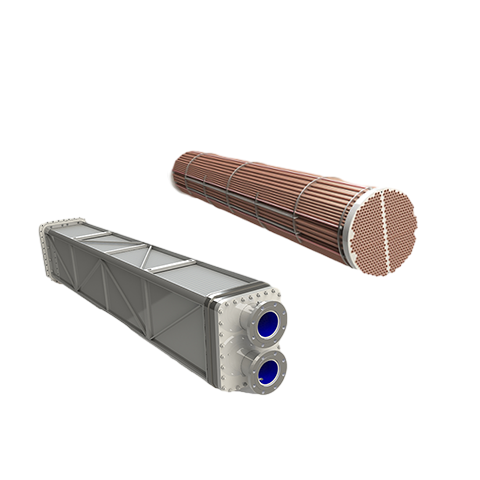

Finned Tubes Used In Shell & Tube Heat Exchangers

Finned Tubes Used For Equipment Manufacturers

Your long-term China partner of fin tube for heat exchangers

Our Factory Insight

Certificates

Production Videos

Stay tuned for our upcoming video series, where we delve deeper into our products and processes, showcasing how we produce finned copper pipes.

Get Free Quote

Custom Fin Tube With Easy

Step 1: Tell Us What You Need

Tell us as specific as possible of your needs, provide detailed specification and the drawing.

Step 2: Get Solution & Quote

We will work out the best solution according to your requirements, we try our best to quote within 24 hours.

Step 3: Approve for Mass Production

We will start mass production after getting your approval and deposit, and we will handle the shipment.