Custom Fin Tubes Fanctory Based In China

Trusted Copper Tubes Manufacturer Since 1984

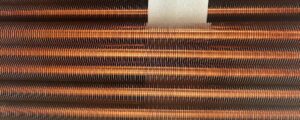

Cufin Tube Factory is a leading player in China’s copper tubing industry, specializing in the research, development, and production of high-performance, efficient copper and copper alloy finned tubes for heat exchange applications.

As a key contributor to the formulation of national and industry standards, we are recognized as a National Torch Plan Key High-Tech Enterprise and rank among China’s top 10 copper tube manufacturers. With over 40 years of innovation, we remain committed to advancing the development of high-end, eco-friendly heat exchange tubes.

Our products are widely used across various industries, including air conditioning and refrigeration, power generation, marine, military, nuclear power, seawater desalination, petrochemicals, and large-scale construction projects.

Your Reliable Partner For Copper Finned Tubing

We are your trusted partner for high-quality copper finned tubing and heat exchanger components.With decades of expertise, we offer solutions for HVAC, boilers, oil & gas, energy generation, and more. Discover why businesses globally rely on us for superior performance and cost efficiency.

Our Value

We are committed to delivering reliable products, fostering long-term partnerships, and minimizing environmental impact.

Quality, innovation, customer satisfaction, integrity, and sustainability.

Our Vision

To become a global leader in the heat exchanger component industry by continuously innovating, and offering cost-effective solutions that contribute to a greener and more energy-efficient future.

Our Mission

To provide high-quality, efficient, and durable finned tubes and heat exchanger solutions that meet the rigorous demands of industries worldwide, helping businesses improve energy efficiency and sustainability.

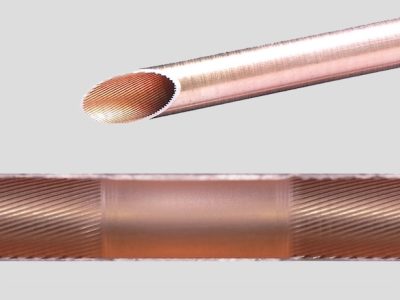

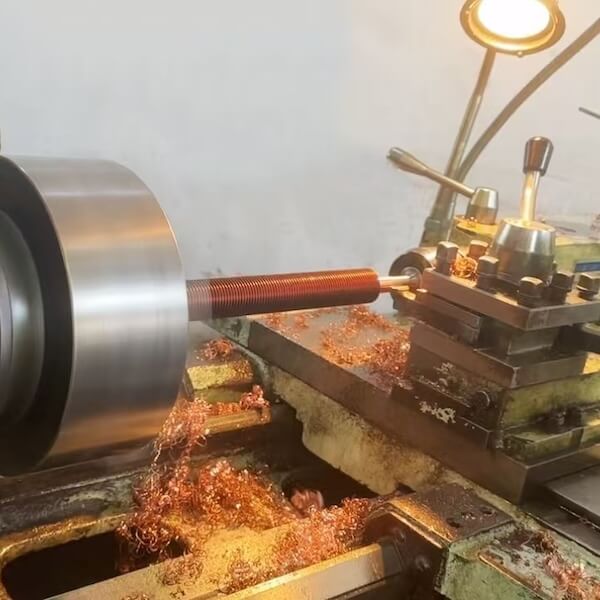

Finned Tubes Manufacturing Process

After your order is confirmed, we first prepare the raw copper tubes, which are then extruded. Before cutting the tubes to the specified length, an intermediate step is conducted — leak testing by 2 MPA Pressure. Then cut to length. Following this, the tubes undergo smooth section turning and cleaning, after which they are dried to remove water.

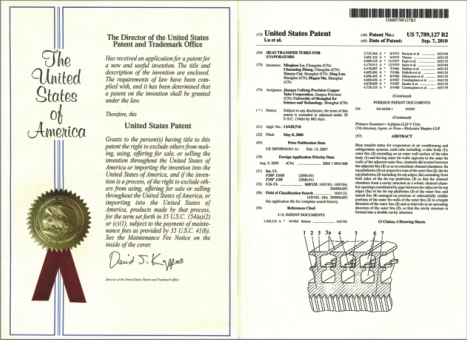

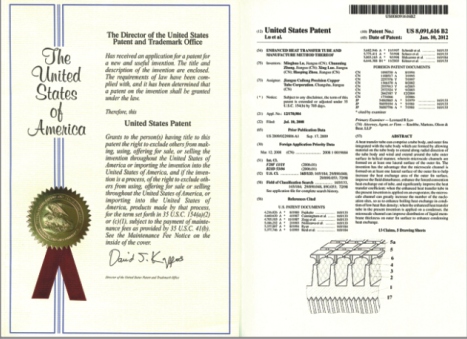

Certified Expertise & Advanced Technology

With over 30 advanced machines and state-of-the-art manufacturing processes, we guarantee consistent, high-quality products and cost-effective solutions.

Our factory could compete with top brands from Germany and USA, offering premium quality at competitive prices.

Exporting to over 20 countries, we ensure on-time delivery and responsive customer service.

Precision-engineered finned tubes tailored to your needs

With over 30 advanced machines and state-of-the-art manufacturing processes, we guarantee consistent, high-quality products and cost-effective solutions.

Our factory could compete with top brands from Germany and USA, offering premium quality at competitive prices.

Exporting to over 20 countries, we ensure on-time delivery and responsive customer service.

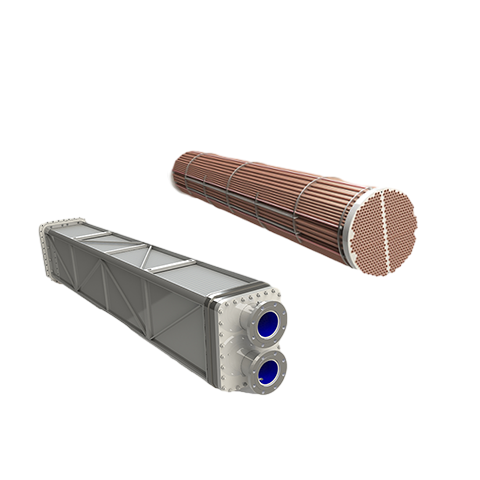

Primary Industries & Applications

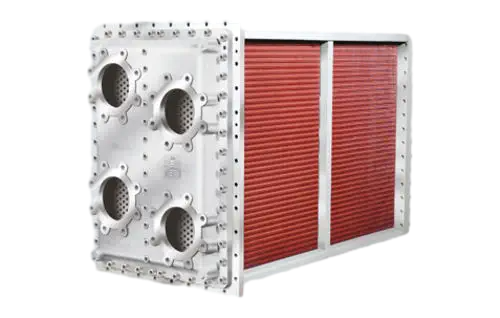

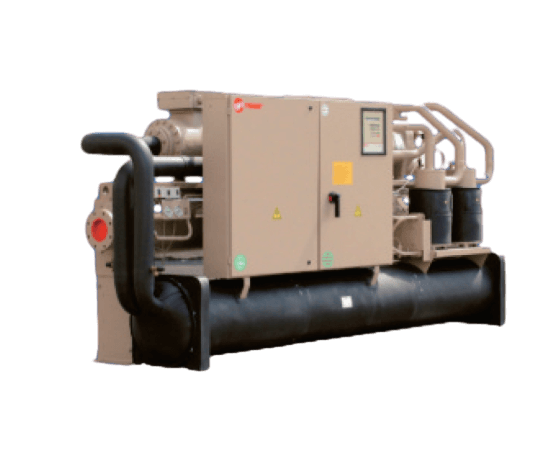

Fin Tubes Used In HVAC & Cooling Systems

Finned tubes are crucial in HVAC and cooling systems, enhancing heat transfer efficiency. They increase the surface area available for heat exchange, allowing for effective heating and cooling of air. Commonly used in air conditioning units and refrigeration systems, finned tubes facilitate rapid temperature control, improving overall system performance and energy savings. Their design enables efficient handling of large air volumes in confined spaces, making them ideal for various industrial applications.

Finned Tubes Used In Gas-Fired Boilers

Finned Tubes Used In Cooling Towers

Finned Tubes Used For Oil & Gas Suppliers

Finned Tubes Used In Mining Equipments

Finned Tubes Used In Water Heater

Finned Tubes Used In Shell & Tube Heat Exchangers

Finned Tubes Used For Equipment Manufacturers

Your long-term China partner of fin tube for heat exchangers

We are trusted by customers all around the world!

Expertise in providing energy-efficient components for HVAC systems, boilers, and industrial cooling.

Mike Wood

Mr. Wood at Facebook

“CufinTube provides reliable, durable, and efficient heat exchanger components. Their team is always available to support us with technical advice and fast delivery.”

Arlene McCoy

Graphic at Facebook

“We’ve been using Cufin Tube’s fin tubes for years. The quality is unmatched, prices are competitive, and they always meet our delivery deadlines.”

Certificates

Production Videos

Stay tuned for our upcoming video series, where we delve deeper into our products and processes, showcasing how we produce finned copper pipes.

Frequently Asked Questions

About Heat Exchanger Fin Tubes

What is the lead time for copper finned tubes after placing an order?

Our typical lead time for copper finned tubes is 4-6 weeks after the order confirmation, depending on the order quantity and product specifications.

Can you provide product samples for testing before we place a large order?

What are your payment terms for international orders?

Our standard payment terms are 30% T/T in advance, with the remaining 70% payable before shipment. We are open to discussing flexible terms for long-term customers.

Do you offer customization options for tube sizes and fin specifications?

What quality control measures are in place during production?

Our factory is ISO-certified. We adhere to strict quality control measures, including raw material inspections, in-process checks, and final product testing with testing report issued and shared with customer.

Can you provide certificates of material origin and quality for your finned tubes?

Yes, we can provide all necessary certificates, including material origin, quality reports, and third-party inspection reports if required.

What packaging do you use to ensure the safe transport of finned tubes?

We use sturdy wooden crates with proper internal supports and protective wraps to ensure that the finned tubes arrive safely without damage during shipping.

How do you handle fluctuations in raw material prices?

We understand price stability is important. We strive to maintain competitive pricing and offer options like fixed-price contracts for long-term customers to mitigate the impact of raw material price fluctuations.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!