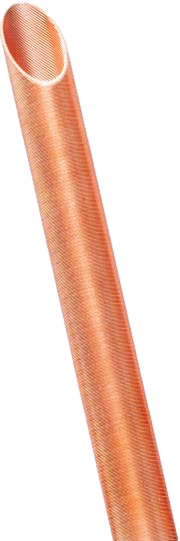

Condenser Tube

Enhanced surface tube, optimized surface for highly efficient heat transfer

Copper Condenser Tube Manufacturer

As a leading copper condenser tube manufacturer, we specialize in copper finning pipes, spiral finned tube with world-class solid state technology and perfected fin tube design. For condenser tubes, such enhanced surface tubes have significantly higher heat transfer coefficients, and vastly used in power plants, HVAC systems, and industrial processes, ensuring long-lasting performance and reliability in demanding environments.

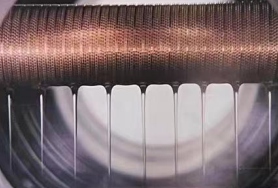

Technical Specification:

- Proprietary design

- Fin end is equipped with sharp protrusion in both radial and axial direction

- The sharp protrusion can puncture the liquid film of refrigerant, destroy it’s surface tension and accelerate the dripping of condensation liquid.

- High condensation heat transfer coefficient and remarkable condensation effect.

Main Application:

The condenser tube is especially suitable for:

- Central air conditioning;

- Screw machine and other chillers;

- Shell and tube heat exchangers with small temperature difference conditions;

- Heat exchangers with phase transition

Condenser Tube Parameter

| Code | Standard Size | Standard Size | Plain End | Plain End | Finned Section | Finned Section | Finned Section | Finned Section |

|---|---|---|---|---|---|---|---|---|

| CTHC | Outside Diameter(mm) | Nominal Wall(mm) | Outside Diameter(mm) | Nominal Wall(mm) | Outside Diameter(mm) | Fin Height (mm) | Min Wall Under Fins(mm) | Fin Per Inch(mm) |

| A-4 | 19.05 | 0.635 | 19.05 | 1.03 | 18.9 | 0.9 | 0.56 | 48 |

| A-4+ | 25.4 | 0.635 | 25.32 | 1.05 | 25.15 | 0.85 | 0.56 | 48 |

| A-4+L | 25.4 | 0.635 | 25.32 | 1.07 | 25.27 | 0.8 | 0.56 | 46 |

| A-5 | 19.05 | 0.635 | 19.05 | 1 | 18.9 | 0.75 | 0.585 | 42 |

| A-5+ | 25.4 | 0.635 | 25.32 | 1.02 | 25.15 | 0.75 | 0.56 | 42 |

| A-5WR | 19.05 | 0.635 | 19.05 | 1 | 18.9 | 0.7 | 0.585 | 42 |

What Is Condenser Tube?

Condenser tubes are critical components in various heat exchange systems, particularly in industrial applications such as power plants, refrigeration, and chemical processing. Their primary function is to facilitate the condensation of gases or vapors into liquids by efficiently transferring heat from the hot gaseous refrigerant to a cooler external medium, typically water or air.

Condenser tubes are essential for efficient thermal management in numerous industrial processes, ensuring that systems operate smoothly while maximizing energy use and minimizing waste.

Functionality of Condenser Tubes

Heat Transfer: The condenser tube operates by allowing hot vapor to flow through the inside of the tube while a cooling medium flows around it. As the vapor loses heat to the cooler medium, it condenses into a liquid form. This process is essential for maintaining system efficiency and stability.

Energy Recycling: By converting vapor back into liquid, condenser tubes play a vital role in energy recycling within thermal systems. This transformation not only conserves energy but also enhances operational sustainability and reduces costs.

Design and Materials Of Condenser

Construction: Condenser tubes are typically made from materials such as copper-nickel alloys, brass, stainless steel, and titanium. The choice of material depends on factors like corrosion resistance, thermal conductivity, and cost-effectiveness. For example:

- Copper: Excellent heat transfer properties.

- Brass: Good for seawater applications due to its corrosion resistance.

- Titanium: Preferred in corrosive environments but more expensive.

Dimensions: Standard outer diameters for condenser tubes are commonly 5/8″, 3/4″, and 1″, with variations for specific applications. Tubes can also be enhanced internally or externally to improve efficiency.

Applications Of Condenser Tube

Condenser tubes are integral in several systems:

HVAC Systems: Condenser tubes are used in heating, ventilation, and air conditioning systems to remove heat from refrigerants, thereby maintaining desired indoor climates efficiently

Power Plants: They condense steam back into water, maximizing efficiency in the steam cycle.

Refrigeration Systems: Used in chillers to condense refrigerants during the cooling cycle.

Oil Refining: In the oil refining process, condenser tubes are critical for controlling temperatures in high-heat environments, such as cracking and reforming units. They help maintain optimal conditions for chemical reactions, ensuring product quality and efficiency

Other Applications Including :

- Marine Applications

- Chemical Processing

- Pharmaceutical Manufacturing

- Food Processing

- Pipeline Transportation

- Waste Heat Recovery Systems

- Natural Gas Processing

- District Heating Systems

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

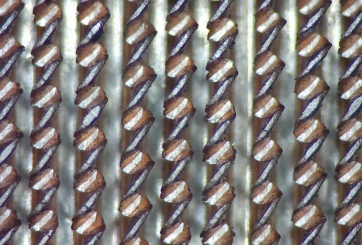

Mass Production Photos

Check how we will produce your finned tube bulk orders in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Condenser Heat Exchanger Tubes

What materials do you use for manufacturing condenser heat exchanger tubes?

Our condenser heat exchanger tubes are mainly made from high-quality copper, as well as copper-nickel alloys, stainless steel, and titanium to provide excellent heat transfer, corrosion resistance, and durability.

Can you provide tubes with finned surfaces for increased heat transfer efficiency?

Can your tubes handle corrosive environments like seawater?

Yes, we offer condenser heat exchanger tubes made from copper-nickel alloys and titanium, both of which are highly resistant to corrosion in seawater and other harsh environments.

Do your tubes comply with international standards?

What are your quality control measures for condenser tubes?

We implement rigorous quality control processes, including pressure testing, eddy current testing, and material composition analysis to ensure each tube meets the highest standards of durability and performance.

Can you provide custom tube designs for specific condenser requirements?

Yes, we offer customization services for condenser tubes, including modifications in diameter, length, and fin configuration to suit specific system requirements.

What packaging do you use to ensure the safe transport of finned tubes?

We use sturdy wooden crates with proper internal supports and protective wraps to ensure that the finned tubes arrive safely without damage during shipping.

What is the lead time for bulk orders of condenser heat exchanger tubes?

Lead time varies depending on the order size, but generally, we fulfill bulk orders within 4-5 weeks. For urgent orders, we can expedite production.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!