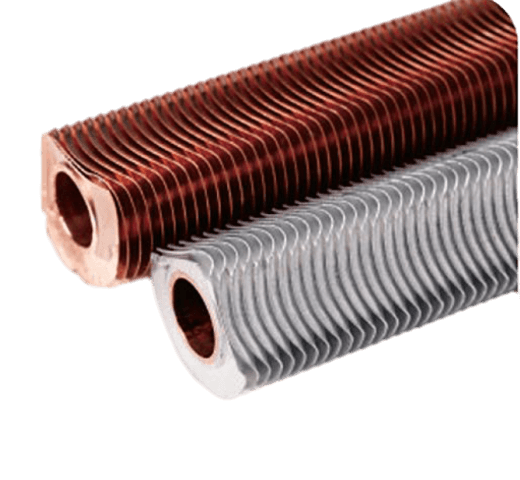

Custom Your Heat Exchanger Finned Tubes

Custom heat exchanger finned tubes, such as low finned tube, medium-high finned tube, saw-tooth tube, internal cross-tooth heat exchanger tube....

Custom Heat Exchanger Finned Tubes

Custom heat exchanger finned tubes are designed for optimal thermal efficiency in various industries such as HVAC, petrochemical, and power generation. With superior heat transfer and corrosion resistance, they ensure reliable performance in harsh environments, making them ideal for condensers, evaporators, and industrial heat exchangers.

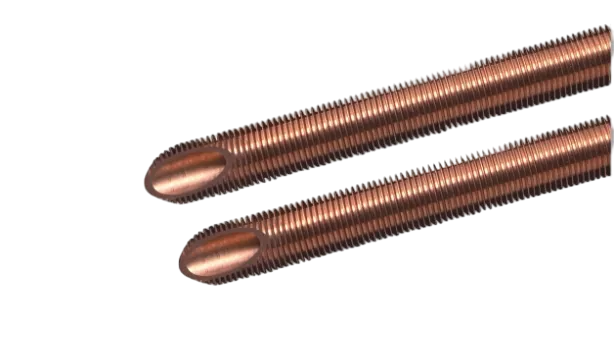

Custom Low Finned Tubes

Design and Structure: Low finned tubes have fins formed directly from the tube material through processes such as cold deformation or rolling, ensuring that the fins are securely attached and do not detach even under bending stresses.

The fin height is typically low (around 1/16th of an inch), allowing the outer diameter to remain compact, which is advantageous for fitting through tight spaces in heat exchangers.

Applications: Commonly used in heat exchangers, low finned tubes are effective in applications such as air conditioning systems, refrigeration, power generation, and chemical processing. Their design allows them to efficiently transfer heat between fluids in both liquid-to-liquid and gas-to-liquid scenarios.

Performance Advantages & Customization

By increasing the external surface area by 2.5 to 3 times compared to bare tubes, low finned tubes enhance heat exchange efficiency without requiring larger equipment sizes. This compactness is particularly beneficial in industries where space is limited.

Customization options include variations in fin pitch (the spacing between fins), fin height, and tube dimensions. This flexibility allows for optimization based on specific operational conditions or fluid characteristics

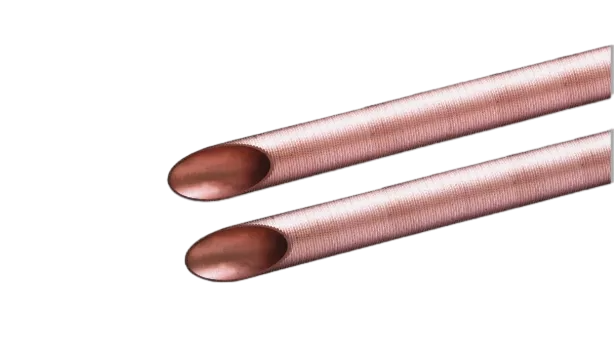

Custom Medium-high Finned Tubes

Medium-high finned tubes are specialized heat exchange components that enhance thermal efficiency through their unique design. They feature fins that are integral to the tube, typically with a fin height of around 3 mm (approximately ⅛ inch), which is higher than that of low finned tubes.

A notable advantage of medium-high finned tubes is their flexibility in bent applications. The manufacturing process allows for tight bend radii without compromising structural integrity, making them versatile for different configurations.

Cufin Tube can customize these tubes based on specific requirements, including fin density and grain size, to optimize performance for particular applications. This customization is crucial for ensuring compatibility with various operational conditions

Custom Internal Cross-tooth Finned Tube

The Internal Cross-tooth Finned Tube features an innovative internal structure designed with cross-tooth patterns inside the tube. These internal fins create turbulence as fluid flows through, significantly improving heat transfer efficiency by disrupting laminar flow and increasing surface contact with the fluid. This design is particularly effective in heat exchangers used in demanding environments, such as power generation, chemical processing, and HVAC systems.

At Cufin Tube, we offer fully customizable solutions for these finned tubes, tailored to meet your specific application needs. Whether it’s selecting the right materials, adjusting fin dimensions, or optimizing the internal tooth structure, our expert engineering team works closely with you to ensure maximum performance and durability for your heat exchange systems.

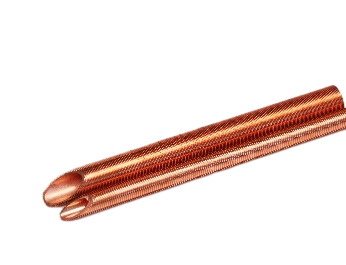

Custom Saw-tooth Finned Tubes

Saw-tooth finned tubes are a specific type of finned tube designed to enhance heat transfer efficiency in various applications. The unique saw-tooth profile of the fins increases the surface area available for heat exchange while also promoting turbulent flow, which further improves thermal performance.

Design: The fins on saw-tooth finned tubes are shaped like a series of saw blades, creating a distinctive profile. This design allows for greater surface area compared to traditional straight or helical fins, facilitating improved heat transfer capabilities.

Heat Transfer Efficiency: The saw-tooth configuration helps disrupt the boundary layer of fluid flowing over the fins, enhancing turbulence. This increased turbulence results in better mixing of the fluid and more efficient heat exchange between the fluid inside the tube and the surrounding environment.

Applications: These tubes are commonly used in heat exchangers, condensers, and evaporators across various industries, including HVAC systems, power generation, and chemical processing. Their ability to handle high flow rates makes them suitable for applications requiring rapid heat transfer.

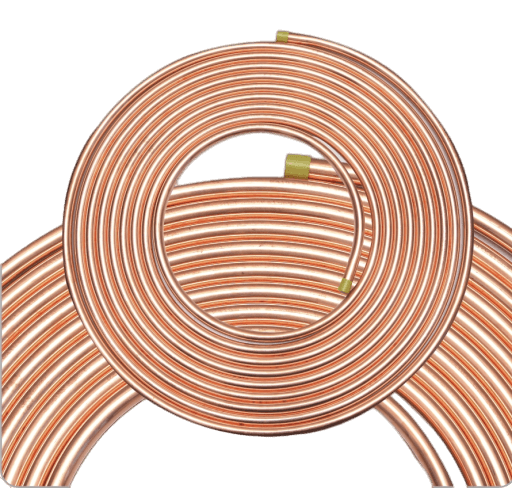

Now Custom Pancake Coil Copper Tubes

Our Custom Pancake Coil Copper Tubes are precision-engineered for a variety of HVAC, refrigeration, and plumbing applications. These coils are made from high-quality copper, offering excellent thermal conductivity, corrosion resistance, and flexibility for easy installation in tight spaces. Pancake coils are ideal for air conditioning units, heat exchangers, and water supply systems, ensuring efficient heat transfer and long-lasting performance.

Cufin Tube offers customization options for coil sizes, lengths, and diameters to meet your specific project requirements. Trust us for consistent quality and tailored solutions that optimize the performance of your systems.

Custom High Finned Tube With Bent Fins

High finned tubes with bent fins are specialized heat exchange components designed to maximize thermal efficiency in various applications. These tubes feature fins that are not only taller than those found on low or medium-high finned tubes but also incorporate a unique bending design that enhances fluid dynamics and heat transfer.

Design:The bending of the fins allows for better airflow and fluid movement, promoting turbulence that enhances heat transfer efficiency.

Heat Transfer Efficiency: The combination of high fin height and bent configuration facilitates improved heat transfer by disrupting the boundary layer of the fluid flowing over the fins. This disruption leads to increased turbulence, which is beneficial for applications requiring rapid heat exchange.

Applications: High finned tubes with bent fins are commonly used in applications such as boilers, condensers, and evaporators, particularly in industries like power generation, petrochemicals, and HVAC systems. Their design makes them suitable for high-temperature and high-pressure environments.

Custom Your Heat Exchanger Fin Tubes

Our Custom Heat Exchanger Finned Tubes are fully customizable to meet your specific operational needs. You can choose from a range of materials such as copper, stainless steel, or titanium, tailored to withstand extreme temperatures or corrosive environments. Additionally, we offer options for fin size, spacing, and thickness, ensuring optimal heat transfer efficiency. Whether for HVAC, power generation, or industrial processes, we adapt every detail to fit your system’s requirements, providing precise solutions that enhance performance and longevity.

Main Applications Including:

- Food Processing

- Marine Applications

- Natural Gas Treatment

- Gas Recovery Systems

- Steam Coils

- Timber Drying

- Air-Cooled Heat Exchangers

- Textile Industry

- Waste Heat Recovery

- Industrial Ovens

Book A Video Call

Your reliable China partner of Custom finned tubes for heat exchangers

Mass Production Photos

Check how we will produce your finned tube bulk orders of in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About custom finned tubes for heat exchangers

Can you customize the finned tubes based on specific materials and dimensions?

Yes, we offer full customization on both materials and dimensions. You can choose from copper, stainless steel, titanium, or other alloys, and specify the tube length, diameter, fin height, spacing, and thickness according to your heat exchanger’s requirements.

Can you produce finned tubes for high-temperature or corrosive environments?

What information do you need to provide a custom quote?

To provide an accurate quote, we need details on the material, tube diameter, fin type, fin height, spacing, operating conditions (temperature, pressure, fluid type), and the quantity required.

What is the lead time for custom finned tube orders?

Lead time typically depends on the complexity of the customization and the quantity required. For most custom orders, our standard lead time is 4 to 5 weeks, but we can expedite production if necessary.

What are the available fin types for heat exchangers?

Can you assist in the design of finned tubes for specific heat exchanger applications?

Yes, we have a team of experienced engineers who can collaborate with you to design the most effective finned tube configuration based on your heat exchanger’s operating conditions and performance goals.

What are the packaging and shipping options for custom finned tubes?

We ensure that all custom finned tubes are securely packaged to prevent damage during transit. Packaging can be tailored to your specific requirements, and we offer flexible shipping options, including air, sea, or land freight, depending on your location and urgency.

What quality control measures do you follow for custom finned tubes?

We follow strict quality control procedures, including material inspections, dimensional checks, pressure tests, and thermal performance validation. All custom finned tubes undergo rigorous testing to ensure they meet your specifications and perform reliably in your application.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!