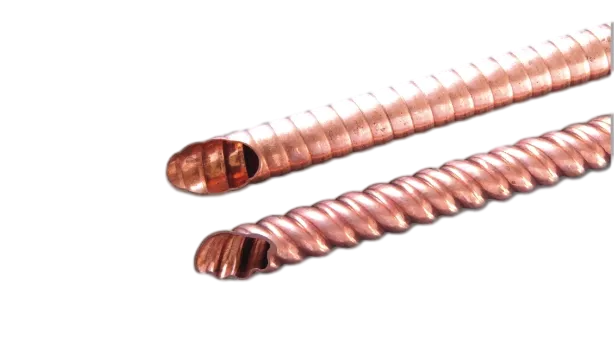

Spiral Tube

China Spiral Heat Exchanger Tube Manufacturer

China Spiral Heat Exchanger Tube Manufacturer

We specialize in producing durable and efficient spiral tubes designed for optimal heat transfer in various applications. Our advanced manufacturing techniques ensure consistency and reliability, meeting the needs of industries like HVAC, petrochemicals, and energy generation. Partner with us for innovative solutions and competitive pricing tailored to your specific requirements. Let’s enhance your operations with our superior products!

Technical Specification:

- Spiral tubes are approximately 15% stronger than longitudinally welded tubes due to their construction method

- Pipe Thickness: Typically between 1.6 mm and 5.0 mm .

- Standard Lengths: Commonly available in lengths of 6.0 meters, with custom lengths up to 15 meters possible.

Main Application:

Spiral tubes are commonly employed in:

HVAC Systems: For heating, ventilation, and air conditioning.

Liquid Transfer: Used in various fluid transport applications.

Wastewater Management: Effective for handling sewage and other waste liquids.

Irrigation and Pumping: Utilized in agricultural settings for water distribution.

What Is Spiral Tube?

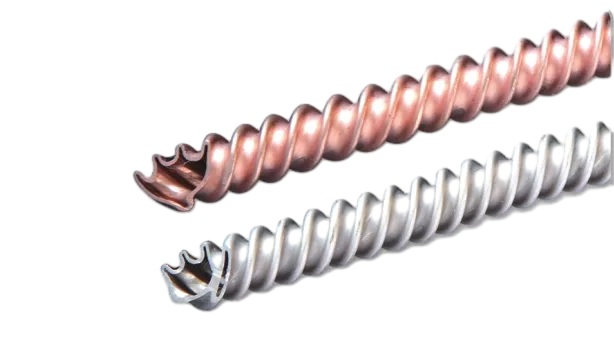

A spiral tube is a type of tubing that is formed in a helical or spiral shape. This design can enhance fluid flow characteristics and increase surface area, making it effective for heat exchange applications. Spiral tubes are often used in heat exchangers, condensers, and evaporators, where efficient heat transfer is essential. According to the production materials, it can be divided into carbon steel spiral tube, stainless steel spiral tube and alloy spiral tube, etc.

In heat exchangers, spiral tubes facilitate efficient heat transfer by allowing fluids to flow in opposite directions within coiled tubes. The design promotes turbulence and secondary flow patterns that enhance heat exchange efficiency significantly compared to traditional systems.

Key Advantages of Spiral Tubes

Increased Surface Area: The spiral design maximizes contact between the fluid inside the tube and the surrounding environment, improving heat transfer efficiency.

Compact Design: Their shape allows for a more compact setup compared to straight tubes, making them suitable for applications with space constraints.

Flexibility: They can be fabricated from various materials, including metals and plastics, making them versatile for different industries.

How Do Spiral Tubes Work?

Spiral welded tubes are created by spirally forming a coil of metal into a tube, which is then fused through a fusion welding process. This method involves the following steps:

Coiling: A continuous strip of metal is coiled into a spiral shape.

Welding: The edges of the coil are welded together using high-frequency induction or other welding techniques. This creates a strong, seamless tube.

Surface Treatment: After welding, the tubes undergo pickling and passivation in an acid bath to remove impurities and enhance corrosion resistance.

These tubes are commonly used in HVAC systems, liquid transfer, wastewater management, and irrigation due to their durability and efficiency in fluid transport.

Benefits of Spiral Tube in HVAC Systems

Using spiral tubes in HVAC systems offers several significant benefits that enhance efficiency, reduce costs, and improve indoor air quality. Here are the key advantages:

- Low Air Leakage

- Improved Airflow Efficiency

- Cost-Effectiveness

- Quieter Operation

- Ease of Maintenance

- Space Efficiency

In summary, spiral tubes in HVAC systems provide a combination of efficiency, cost-effectiveness, reduced noise levels, and easier maintenance, making them an attractive option for modern heating and cooling solutions.

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

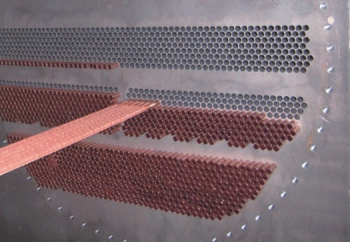

Mass Production Photos

Check how we will produce your finned tube bulk orders of in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Spiral Tubes For Heat Exchangers

What materials are your spiral heat exchanger tubes made from?

Our spiral heat exchanger tubes are available in various materials, including copper, cupronickel, stainless steel, and titanium, ensuring suitability for diverse applications.

What are the standard dimensions available for your spiral tubes?

Do you offer testing and quality assurance for your spiral tubes?

Absolutely! Each batch undergoes rigorous testing, including pressure tests and dimensional inspections, to ensure quality and performance meet industry standards.

What are your payment terms?

Are your spiral tubes suitable for corrosive environments?

Yes, we also could offer specialized spiral tubes made from corrosion-resistant materials like titanium and cupronickel, ideal for harsh environments in industries such as petrochemicals.

Can you assist with design and engineering support for our heat exchanger project?

Certainly! Our experienced engineering team is available to provide design support and assist you in optimizing the heat exchanger performance with our spiral tubes.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!