In heat exchanger design, the arrangement of tubes and the direction of fluid flow play a crucial role in determining the system’s efficiency. A common question arises in industries dealing with air-to-liquid heat exchange: Are fins used when the flow direction is across or at a right angle to the tubes? This question is essential, especially when dealing with large heat exchangers in industries like HVAC, power generation, or chemical processing. To understand the role of fins in this scenario, we must first take a closer look at the mechanics of heat exchange and how flow direction affects the performance of the system.

Understanding Flow Direction in Heat Exchangers

Heat exchangers are designed to transfer heat between two or more fluids without mixing them. The efficiency of this heat transfer process can be significantly influenced by how the fluids flow over the heat exchange surfaces. There are several flow configurations in heat exchangers, such as parallel flow, counterflow, and crossflow.

In crossflow heat exchangers, the direction of the fluid flow is perpendicular (or at a right angle) to the tubes. This means that one fluid flows horizontally (or across the tubes), while the other fluid flows vertically through the tubes. Crossflow heat exchangers are commonly used in applications where space constraints or design considerations require such a configuration, like air-cooled radiators or certain types of industrial cooling systems.

The next important question is: Are fins still used in heat exchangers when the fluid flows across the tubes in this manner?

The Role of Fins in Heat Exchanger Design

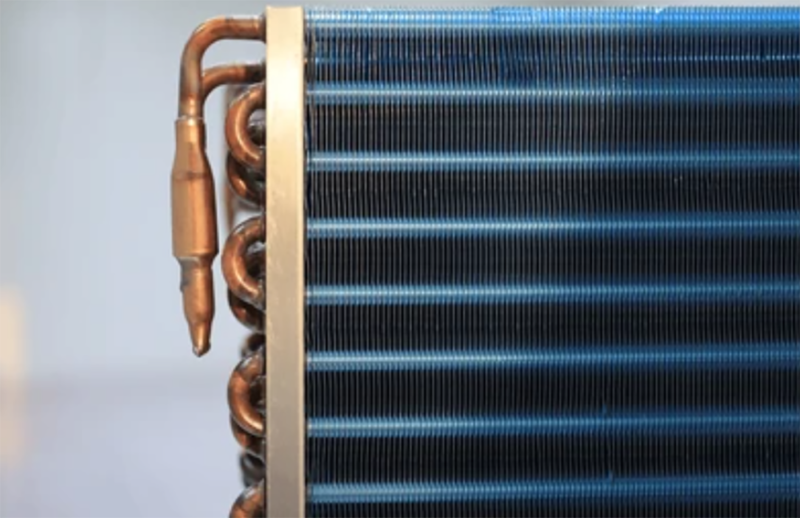

Fins are thin metal surfaces that are often added to heat exchangers to increase the surface area for heat transfer. In most heat exchangers, fins are attached to tubes to enhance the heat exchange process between the fluid and the tube surface. The purpose of fins is to improve the efficiency of heat transfer by creating more surface area for heat to flow between the fluid and the tubes.

Fins are particularly useful in air-to-liquid heat exchangers, where the air passes over the fins and transfers heat to or from the fluid within the tubes. The fins help facilitate this heat transfer by increasing the area through which heat can be transferred, thereby improving the heat exchanger’s overall efficiency.

Do Fins Still Play a Role in Crossflow Heat Exchangers?

In crossflow heat exchangers, the fluid flows across the tubes, which presents a different set of challenges and opportunities for heat exchange efficiency. While fins can still be used in crossflow heat exchangers, the reasoning and design considerations are slightly different compared to conventional parallel-flow heat exchangers.

Here are several key factors that determine whether fins are necessary or beneficial when the direction of flow is at a right angle to the tubes:

1. Heat Transfer Efficiency in Crossflow

In crossflow heat exchangers, the flow dynamics differ from other configurations. The fluid moving across the tubes tends to form turbulence, which increases the heat transfer rate between the fluid and the tube surface. However, the efficiency of heat transfer may still be lower than in parallel or counterflow systems, where the fluid stays in contact with the tube surface for longer periods. In such cases, the use of fins becomes even more critical.

Fins are added to crossflow heat exchangers primarily to increase the surface area for heat exchange, compensating for the less efficient flow dynamics compared to other configurations. The turbulence generated by the crossflow can be harnessed more effectively when there is an expanded surface area for the heat transfer, which is why fins are still widely used in many applications.

2. Application Specifics

Crossflow heat exchangers are typically used in applications like air-to-air or air-to-liquid cooling, where space is limited, and the fluid being cooled or heated is not under high pressure. In such systems, the addition of fins can significantly improve the heat transfer rate, particularly when the heat load is moderate or the temperature differences between fluids are not extreme.

In air-cooled systems, such as radiators or cooling towers, fins are essential in increasing the surface area for heat exchange. As the air flows across the tubes, fins maximize the interaction between the fluid in the tubes and the ambient air, improving cooling efficiency. For instance, in HVAC systems where air is used as a coolant, the fins help optimize the exchange of heat between the air and the tubes, even if the flow direction is across the tubes.

3. Space and Design Considerations

Fins are often used when space is a concern, and they can help achieve a compact design with higher heat transfer performance. In cases where the flow direction is across the tubes, especially when used in air-based heat exchangers, fins provide a simple, cost-effective solution to increase surface area without significantly increasing the size of the unit. This is especially important in large industrial systems where space is at a premium.

In applications like refrigeration or air conditioning, the compact nature of finned tube designs allows manufacturers to meet the required cooling capacity while minimizing the physical footprint of the system. Even when the flow is perpendicular to the tubes, the efficiency improvements offered by fins remain advantageous.

4. Limitations of Finned Tubes in Crossflow

While fins are highly effective in enhancing heat transfer, there are some limitations when the fluid flows across the tubes. The use of fins in crossflow heat exchangers may not always be as effective as in other configurations. The reason lies in the flow pattern – in crossflow systems, the fluid tends to “skim” over the tubes, and much of the turbulence is lost after it passes over the tube surface. As a result, the efficiency gained by adding fins may be less pronounced than in parallel-flow or counterflow systems.

When Are Fins Essential for Crossflow Heat Exchangers?

Fins are most useful in crossflow heat exchangers when:

- There is a need for compact designs: In air conditioning systems or smaller-scale industrial applications, space-saving designs are important, and fins help optimize the heat transfer process without increasing the unit size.

- The temperature difference is moderate: Fins become highly beneficial when the heat load is not too high, as they can maximize heat exchange efficiency in a moderate-temperature environment.

- Air is the coolant: In applications where air is the heat-exchanging fluid, such as in HVAC systems or cooling towers, fins help increase the surface area to facilitate more efficient heat transfer with the air.

Conclusion

Fins are commonly used in heat exchangers where the direction of flow is across the tubes, especially in applications where the goal is to maximize heat transfer efficiency in confined spaces. By increasing the surface area available for heat exchange, fins help improve the overall performance of crossflow heat exchangers.

In systems where the flow is perpendicular to the tubes, fins still provide significant benefits, particularly in air-cooled applications and compact designs. The efficiency of heat transfer is improved, and the system is able to maintain a smaller physical footprint while delivering optimal performance. However, the use of fins may not be as effective as in other flow configurations, and careful design consideration is needed to maximize their benefit. Whether in industrial HVAC systems, refrigeration, or cooling towers, finned tubes remain a critical component for improving heat exchange in crossflow setups.