By Fin Height

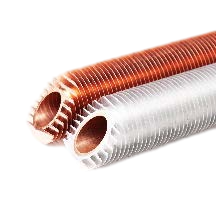

High Finned Tube, Middle Finned Tube, Low Finned Tube, Microfin Tube

Your Reliable Partner For Quality Finned Tubes

We are your trusted partner for high-quality finned tubes and heat exchanger components. Our company produces various types of finned tubes, such as high finned tube, middle finned tube, low finned tube, microfin tube,etc. With decades of expertise, we offer solutions for HVAC, boilers, oil & gas, energy generation, and more. Discover why businesses globally rely on us for superior performance and cost efficiency.

Finned tubes by fin height

High Finned Tube

Relatively low fin density (fewer fins per unit length). High surface area for heat exchange, excellent for applications with large temperature differences. Often used in high-temperature applications like boilers, furnaces, and some types of heat exchangers.

Middle Finned Tube

Moderate fin height and fin density. Balance between surface area and pressure drop, suitable for a wide range of applications. Commonly used in general-purpose heat exchangers, air coolers, and condensers.

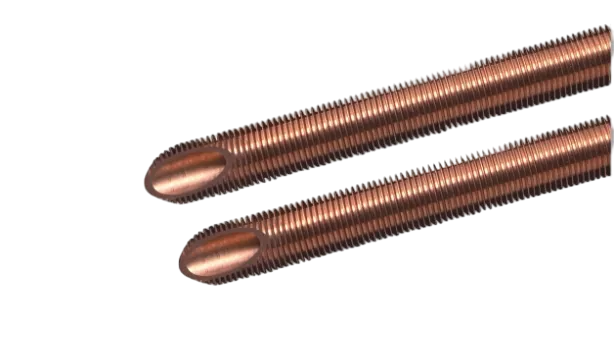

Low Finned Tube

High fin density (more fins per unit length). Minimize pressure drop, suitable for applications with low air velocity. Often used in applications where air flow resistance is a concern, such as automobile radiators and some types of air-cooled condensers.

Microfin Tube

Extremely small fins, often created through specialized manufacturing processes. Very high surface area, excellent for applications requiring maximum heat transfer in a compact space. Used in high-performance applications such as aircraft heat exchangers, electronic cooling, and some types of refrigeration systems.

Applications Of Finned Tubes

Finned tubes are widely used in industries such as:

- Power Generation: Used in heat exchangers for electric, nuclear, and geothermal power plants.

- HVAC Systems: Essential in heating, ventilation, and air conditioning systems for efficient thermal management.

- Refrigeration: Employed in refrigeration units to improve heat exchange efficiency.

- Chemical Processing: Utilized in reactors and heat exchangers within petrochemical and chemical plants.

These tubes play a crucial role in air-cooled heat exchangers, where efficient heat transfer is essential for system performance

Other Applications Including :

- Food Processing

- Marine Applications

- Natural Gas Treatment

- Gas Recovery Systems

- Steam Coils

- Timber Drying

- Air-Cooled Heat Exchangers

- Textile Industry

- Waste Heat Recovery

- Industrial Ovens

Book A Video Call

Mass Production Videos

Stay tuned for our upcoming video series, where we delve deeper into our products and processes, showcasing how we can elevate your brand.

Mass Production Photos

Check how we will produce your finned tube bulk orders in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Fin Tube For Heat Exchangers

What is the lead time for copper finned tubes after placing an order?

Our typical lead time for copper finned tubes is 4-6 weeks after the order confirmation, depending on the order quantity and product specifications.

Can you provide product samples for testing before we place a large order?

What are your payment terms for international orders?

Our standard payment terms are 30% T/T in advance, with the remaining 70% payable before shipment. We are open to discussing flexible terms for long-term customers.

Do you offer customization options for tube sizes and fin specifications?

What quality control measures are in place during production?

Our factory is ISO-certified. We adhere to strict quality control measures, including raw material inspections, in-process checks, and final product testing with testing report issued and shared with customer.

Can you provide certificates of material origin and quality for your finned tubes?

Yes, we can provide all necessary certificates, including material origin, quality reports, and third-party inspection reports if required.

What packaging do you use to ensure the safe transport of finned tubes?

We use sturdy wooden crates with proper internal supports and protective wraps to ensure that the finned tubes arrive safely without damage during shipping.

How do you handle fluctuations in raw material prices?

We understand price stability is important. We strive to maintain competitive pricing and offer options like fixed-price contracts for long-term customers to mitigate the impact of raw material price fluctuations.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!