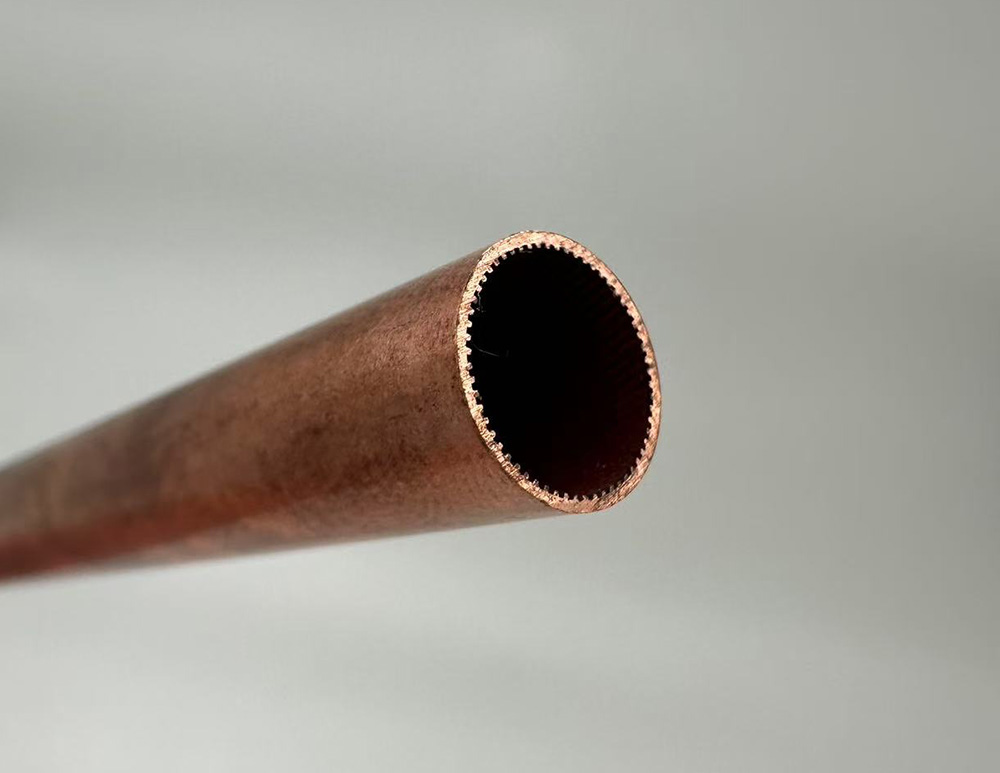

Inner Grooved Tube

A valuable component in various heat exchange systems

China Inner Grooved Tube Supplier

Cufin Tube specializes in inner grooved tube designed for efficient heat transfer in various applications. Our products are crafted using premium stainless steel materials to ensure durability and resistance to corrosion. With advanced manufacturing techniques and over 40 years of experience, we provide customized solutions that meet international standards. Trust us to deliver quality and reliability for your HVAC, petrochemical, and industrial projects.

Tube Dimensions:

Common OD sizes range from 7mm to 12.7mm, with wall thicknesses between 0.2mm and 0.5mm, and groove depths around 0.2mm

Key Features:

Enhanced Heat Transfer: The grooves significantly increase the internal surface area, leading to thermal efficiency improvements of 20% to 30% compared to smooth tubes. This enhancement is achieved through increased turbulence, which disrupts stagnant boundary layers and promotes better mixing of the fluid.

Turbulent Flow Promotion: The grooves facilitate turbulent flow within the tube, which is crucial for effective heat exchange. Turbulent flow enhances heat transfer by ensuring uniform distribution of refrigerant across the tube’s inner surface.

What Is Inner Grooved Tube?

Inner grooved tubes, also known as microfin tubes, are specialized copper or aluminum tubes designed to enhance heat transfer efficiency. These are tubes featuring grooves or indentations on their inner surface. The grooves increase the surface area available for heat transfer, promoting better thermal efficiency. Inner grooved tubes represent a significant advancement in thermal management technology, providing enhanced heat transfer capabilities essential for modern HVAC and refrigeration systems. Their design allows for improved performance while reducing material costs and system size, making them a preferred choice in energy-efficient applications.

Performance Characteristics Of Inner Grooved Tube

Enhanced Heat Transfer Efficiency: Inner grooves significantly increase the surface area of the tube, promoting better heat transfer efficiency. The heat transfer coefficient can be 2 to 3 times higher compared to traditional smooth tubes. The increase in surface area and the promotion of turbulence contribute to more effective heat exchange.

Turbulent Flow Promotion: The grooves disrupt the flow of fluids inside the tube, promoting turbulent flow, which prevents the formation of a stagnant boundary layer and ensures more effective mixing of the fluid.

Improved System Performance: Inner grooved tubes are ideal for use in air conditioning and refrigeration systems as they result in significant energy savings and improved system performance.

Advantages Of Cufin Tube's Inner Grooved Tube

Inner Grooved Tube offer several advantages that make them highly effective in various industrial and commercial applications. Here are the key benefits:

Other Applications Including :

- Corrosion Resistance

- Mechanical Strength and Durability

- Wide Temperature Range

- Enhanced Heat Transfer Efficiency

- Low Maintenance Requirements

- Hygienic Properties

- Compact Design

- Environmental Benefits

In summary, the combination of corrosion resistance, mechanical strength, enhanced heat transfer efficiency, and low maintenance requirements makes inner grooved tube a preferred choice in many demanding applications across various industries.

Applications Of Inner Grooved Tube

- Refrigeration, Heating, and Cooling: Due to copper’s high heat transfer properties in water applications, medium-high fin tubes are commonly used in these industries.

- Heat Exchangers: They serve as key components in heat exchangers, facilitating heat transfer between fluids.

- Specific Equipment: They are frequently found in heaters, water heaters, and process coolers

- Air Conditioning Systems: Inner grooved tubes are commonly used in air conditioning systems to enhance cooling performance and energy efficiency. They are used in both indoor and outdoor units.

- Refrigeration Systems: They are utilized in refrigeration units, including showcase refrigerators, to improve heat exchange and cooling efficiency.

- Heat Exchangers: Inner grooved tubes are essential components in heat exchangers, increasing their overall efficiency. By using inner grooved tubes in fin block heat exchangers, the efficiency of the heat exchanger can be increased up to 30%, depending on the application.

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

Mass Production Photos

Check how we will produce your finned tube bulk orders in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Inner Grooved Tube For Heat Exchangers

How do inner grooved tube improve heat transfer?

The grooves create turbulence within the fluid flowing through the tube, disrupting laminar flow and promoting better mixing of fluid layers, which enhances the convection process and overall heat transfer efficiency.

What applications are inner grooved tubes used in?

They are commonly used in heat exchangers, air conditioning systems, refrigeration units, and other thermal management applications where efficient heat transfer is crucial.

What are the performance benefits of using inner grooved tubes?

Inner grooved tubes can achieve a 20% to 30% increase in thermal efficiency compared to smooth tubes. They also allow for more compact designs, reducing material costs and refrigerant loads.

Are there different designs of inner grooved tubes?

Yes, inner grooves can vary in design, including straight or helical patterns, with different depths and geometries tailored to specific applications and refrigerants.

What maintenance is required for inner grooved tubes?

Regular inspections for corrosion or blockages are recommended. The zinc coating option can enhance corrosion resistance in aggressive environments.

What is the maximum length of inner grooved tubes that you can produce?

We can manufacture inner grooved tubes up to 12 meters in length, depending on your specifications and requirements.

Can you supply samples of inner grooved tubes for evaluation?

Yes, we can provide samples upon request to help you assess the quality and suitability of our products for your specific applications.

What are your lead times for orders of inner grooved tubes?

Our standard lead time is typically 4-5 weeks, but we can expedite production for urgent orders, depending on capacity and requirements.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!