The evaporator is one of the most directly utilized components in the refrigeration system, because it provides a low temperature source for use, and the refrigeration system realizes refrigeration by the evaporator. Evaporator and condenser are heat exchangers, but the role of the condenser with the opposite, the condenser heat dissipation to the outside of the system, the evaporator from the outside of the system to absorb heat; that is, the gas-liquid two-phase refrigerant in the evaporator to absorb the heat of the medium around the evaporator, and gradually gasification until it becomes saturated or superheated vapors, and then leave the evaporator. Because the evaporator inside the refrigerant evaporation temperature and the temperature difference between the temperature of the cooled material is relatively small, usually about 10 ℃; while the condenser inside the refrigerant temperature can reach one hundred and eighty degrees, while the cooling water water or air temperature in the 20-30 ℃ or so, the temperature difference is large, so the condenser heat transfer coefficient is greater than that of the evaporator, the entire heat transfer is more intense, the evaporator and the condenser is close to the structure, but the condenser heat transfer effect than the Evaporator is good.

Types of Heat Exchangers

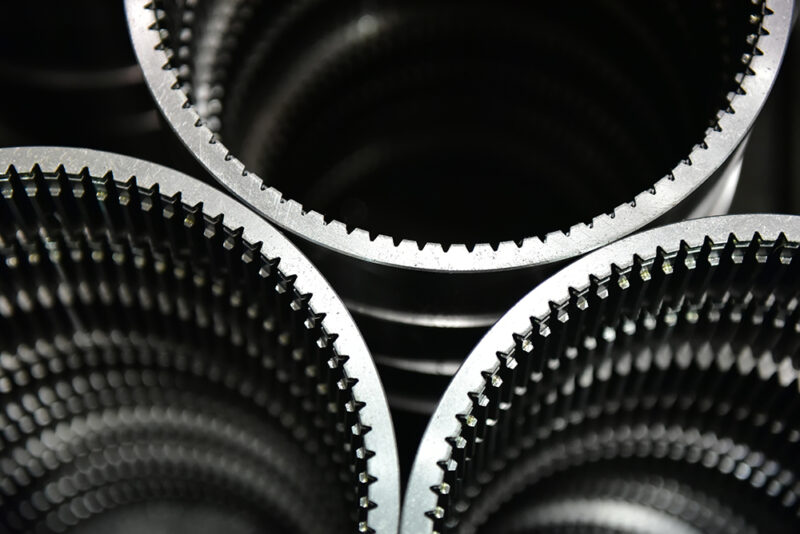

- Shell – and – tube heat exchanger: It consists of a cylindrical shell and a bundle of tubes inside. One fluid flows through the tubes, and the other flows through the shell. This type is widely used in large – scale refrigeration and air – conditioning systems due to its high heat transfer efficiency and ability to handle high – pressure fluids.

- Plate heat exchanger: Composed of a series of thin plates with corrugated surfaces. The fluids flow between the plates, and heat is transferred through the plate material. Plate heat exchangers have a large heat transfer area per unit volume, which makes them suitable for applications where space is limited. They are commonly used in small – and medium – sized air – conditioning systems.

- Fin – and – tube heat exchanger: It has tubes with fins attached to increase the heat transfer area. The air usually flows over the fins, while the refrigerant or other heat – transfer fluids flow through the tubes. This type is widely used in air – conditioning units, such as window air conditioners and split – type air conditioners, as it can effectively transfer heat between the air and the refrigerant.

Functions in Refrigeration and Air Conditioning Systems

- Evaporator: It is responsible for absorbing heat from the indoor air or the space to be cooled. The refrigerant inside the evaporator evaporates as it absorbs heat, changing from a liquid to a vapor state. This process cools the surrounding air, providing the desired cooling effect.

- Condenser: The condenser releases the heat absorbed by the refrigerant in the evaporator to the outdoor environment. The refrigerant vapor, which is at a high temperature and pressure, condenses back into a liquid as it gives off heat to the outside air. This allows the refrigerant to complete the refrigeration cycle and be reused.

- Compression of the refrigerant vapor: After absorbing heat in the evaporator, the refrigerant vapor is drawn into the compressor. The compressor increases the pressure and temperature of the refrigerant vapor.

- Condensation in the condenser: The high – pressure, high – temperature refrigerant vapor then enters the condenser, which is another heat exchanger. In the condenser, the refrigerant vapor releases heat to the outside environment, usually through the air outside. As a result, the refrigerant vapor condenses back into a liquid.

- Expansion and return to the evaporator: The liquid refrigerant then passes through an expansion valve, where its pressure is reduced again. This causes the refrigerant to expand and cool, and it returns to the evaporator to repeat the cycle.

Factors Affecting Heat Transfer Efficiency

- Material properties: The thermal conductivity of the heat exchanger material affects the rate of heat transfer. Materials with high thermal conductivity, such as copper and aluminum, are commonly used to enhance heat transfer efficiency.

- Surface area: Increasing the surface area of the heat exchanger can improve heat transfer. This is why many heat exchangers have fins or other surface – enhancing features to increase the contact area between the fluids and the heat exchanger.

- Fluid flow rate: The flow rate of the fluids through the heat exchanger also affects heat transfer. Higher flow rates can increase the heat transfer coefficient, but they also require more energy to pump the fluids. Therefore, an optimal flow rate needs to be determined to balance heat transfer efficiency and energy consumption.

- Refrigerant circulation: The air conditioning system circulates a refrigerant through a closed loop. The refrigerant is a substance with special thermodynamic properties that can easily change between liquid and vapor states.

- Evaporation in the evaporator: The evaporator is a type of heat exchanger. When the liquid refrigerant enters the evaporator, its pressure drops, causing it to evaporate and change from a liquid to a vapor. During this process, the refrigerant absorbs heat from the surrounding air. The heat exchanger in the evaporator is designed to maximize the contact area between the refrigerant and the air. As the air passes over the evaporator coils, heat is transferred from the air to the refrigerant, causing the air to cool.

As a selection of intermediaries or direct users, if you have the ability to learn how to choose, not too much discussion here. Finally, each manufacturer’s models, types, specifications are different, we make the choice, pay attention to its nominal working conditions. Chiller: as forced convection cooling air evaporator-chiller, now the most common application. Chiller is actually on the basis of set piece evaporator, and the introduction of the fan, usually the fan is generally axial fan. Because of the introduction of the axial fan, the air flow rate is relatively fast, natural convection is generally below 1m/s, the chiller can generally do 2.5 ~ 3m/s, heat transfer coefficient is also greater than the natural convection evaporator 4 ~ 5 times, natural convection evaporator heat transfer coefficient can be done 7 ~ 10 w / (m ² – ℃), forced convection evaporator can be done 30 ~ 40 w / (m ² – ℃). Because the heat transfer coefficient of the chiller is relatively large, so the cooling is relatively fast, the occasion with the chiller because the air flow is relatively fast, relatively small temperature gradient.