The heating and cooling industry is undergoing a significant transformation, driven by a global push for greater energy efficiency and sustainability. Traditional hydronic systems, which rely on high-temperature water, are giving way to modern, low-temperature alternatives that are better suited for today’s high-efficiency equipment. Low-temperature hydronic systems are more efficient, but they require a fundamental rethinking of heat emitters. To effectively transfer heat, these systems rely on advanced finned tube design solutions to maximize British Thermal Unit (BTU) output, ensuring comfortable indoor environments while minimizing energy consumption.

How Finned Tube Material Selection Impacts Performance in Modern Condensing Boiler Applications

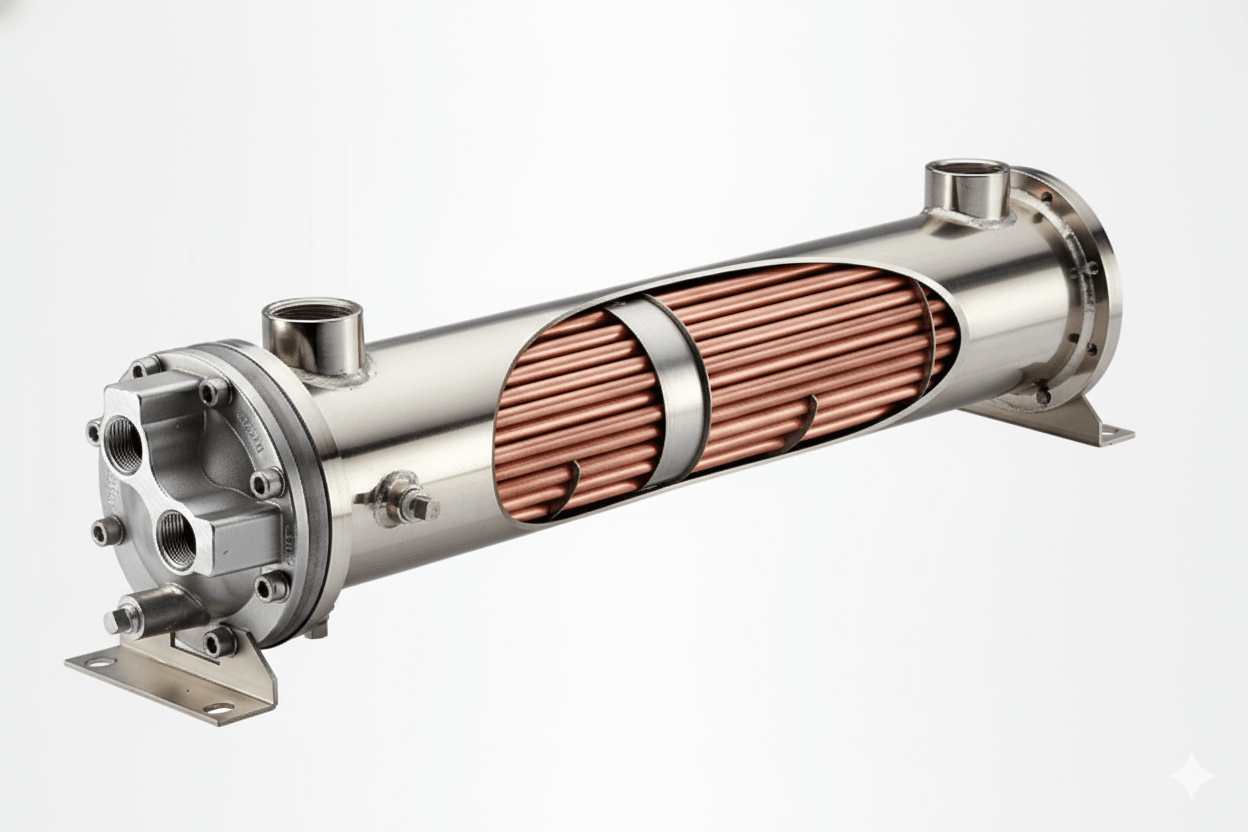

The choice of material is a primary factor in a finned tube’s performance, particularly when paired with modern condensing boilers. These boilers operate at lower temperatures to maximize efficiency by recovering latent heat from flue gases. To effectively transfer this lower-temperature heat, the finned tubes must have excellent thermal conductivity. Materials like copper and aluminum are the most common choices. Copper offers superior heat transfer and corrosion resistance, while aluminum is lighter and more cost-effective. A composite design, often featuring copper tubes with aluminum fins, provides a balanced solution that leverages the best properties of both materials. The correct material selection ensures that the system can operate at the boiler’s lower output temperature without sacrificing heat delivery to the space.

Ground source heat pumps (GSHPs) are highly efficient heating and cooling systems that also operate at lower temperatures. To optimize the performance of commercial finned tube radiation in these applications, the finned tube design must be meticulously tailored. Because the water from a GSHP is cooler, a larger heat transfer surface area is required to achieve the desired BTU output. This can be accomplished through increased fin density, larger tube diameters, or longer runs of finned tubing. The optimization process involves a careful balance between maximizing heat transfer and minimizing air-side pressure drop, which would otherwise increase fan energy consumption in forced convection systems.

The Efficiency Connection: Pairing High-Performance Finned Tubes with Condensing Boilers

The synergy between high-performance finned tubes and condensing boilers is a key to modern energy-efficient heating. By operating at lower return water temperatures, condensing boilers can achieve a higher thermal efficiency, often exceeding 95%. Standard heat emitters, designed for older, high-temperature systems, cannot effectively dissipate the heat from this cooler water. High-performance finned tubes, with their enhanced surface area and optimized design, are engineered to do exactly that. This pairing allows the entire system to operate within its most efficient range, translating directly into significant energy savings and lower operational costs.

Upgrading existing buildings to be more energy-efficient can be a complex challenge. Retrofit strategies for older hydronic systems often involve replacing high-temperature emitters with low-temperature compatible finned tube systems. This allows building owners to transition to more efficient heat sources like condensing boilers or heat pumps without a complete overhaul of the piping infrastructure. The new finned tubes, with their higher BTU output at lower temperatures, can be installed in the same footprint as the old radiators, making for a smooth and cost-effective upgrade.

Comparative Analysis: BTU Output of Standard vs. High-Efficiency Finned Tubes in Green Building Applications

A comparative analysis of the BTU output of standard versus high-efficiency finned tubes highlights their critical role in green building applications. Standard finned tubes, typically designed for 180°F (82°C) water, will see a dramatic drop in BTU output when supplied with 120°F (49°C) water from a heat pump. In contrast, high-efficiency models, with their advanced fin geometries and larger surface areas, can maintain a high BTU output at these lower temperatures. This performance difference is essential for a building to meet its heating load while using a more sustainable heat source.

Optimized hydronic heating is a major contributor to these credits, and advanced finned tube design plays a direct role. By enabling the use of high-efficiency equipment and reducing overall energy consumption, these finned tubes contribute points toward a building’s energy performance rating. Their ability to deliver comfortable heat while operating at lower temperatures is a key component of a high-performance building envelope.

Cost-Benefit Analysis: Investing in Premium Finned Tube Technology for Low-Temperature HVAC Systems

A cost-benefit analysis for premium finned tube technology reveals that a higher initial investment often results in significant long-term savings. The enhanced efficiency of these finned tubes reduces the energy consumption of the entire HVAC system, leading to lower utility bills over the system’s lifetime. When considering the total cost of ownership, the initial premium is quickly offset by these operational savings, making it a sound financial decision for building owners and developers.

The field of finned tube design is constantly evolving, moving beyond traditional designs to incorporate modern innovations. These include new fin shapes that improve airflow and heat transfer, lightweight materials that reduce shipping costs, and modular designs that simplify installation. For energy-efficient commercial buildings, these innovations mean a heating system that is not only more effective but also easier to install and maintain, contributing to a more sustainable and economically viable building.

Specifying Finned Tube Radiation for Net Zero Energy Buildings: Technical Requirements and Best Practices

Net Zero Energy Buildings have incredibly strict energy performance targets. When specifying finned tube radiation for these projects, the technical requirements and best practices are stringent. The finned tubes must be carefully sized to meet the building’s precise heating load at the low operating temperatures of the primary heat source. This requires detailed thermal modeling and a close collaboration between the design team and the manufacturer to ensure the chosen product will perform as intended.

The superior performance of high output finned tubes is the result of a blend of advanced materials, manufacturing, and performance testing. Manufacturers use cutting-edge techniques to bond fins to tubes, ensuring a perfect thermal connection. Rigorous performance testing, including wind tunnel tests and thermal imaging, is used to validate the BTU output under various conditions. This attention to detail in the technology behind the products guarantees that they will deliver on their promise of high efficiency and reliability.