1. High-Efficiency Finned Tube Design for Dry Coolers: Maximizing Heat Transfer in Limited Space

The performance of a dry cooler is directly tied to its heat exchanger design. Finned tube heat exchangers are the core components, and their design dictates the system’s efficiency and physical footprint. In a data center, maximizing heat transfer within a confined space is paramount. High-efficiency designs use a dense arrangement of tubes and fins to create a large surface area for heat exchange. These configurations are carefully engineered to balance a high heat transfer rate with a manageable pressure drop across the coil, which ensures optimal airflow and energy efficiency. The goal is to get the most cooling out of the smallest possible unit, which is essential for urban data center locations where space is at a premium.

Two of the most important design parameters for finned tube heat exchangers are fin spacing and material selection. Fin spacing determines the density of the heat exchange surface. Tighter fin spacing increases the surface area, potentially leading to higher heat transfer. However, it can also raise the risk of fouling and increase the air-side pressure drop, which requires more fan power. The optimal fin spacing is a trade-off that balances thermal performance with operational and maintenance considerations.

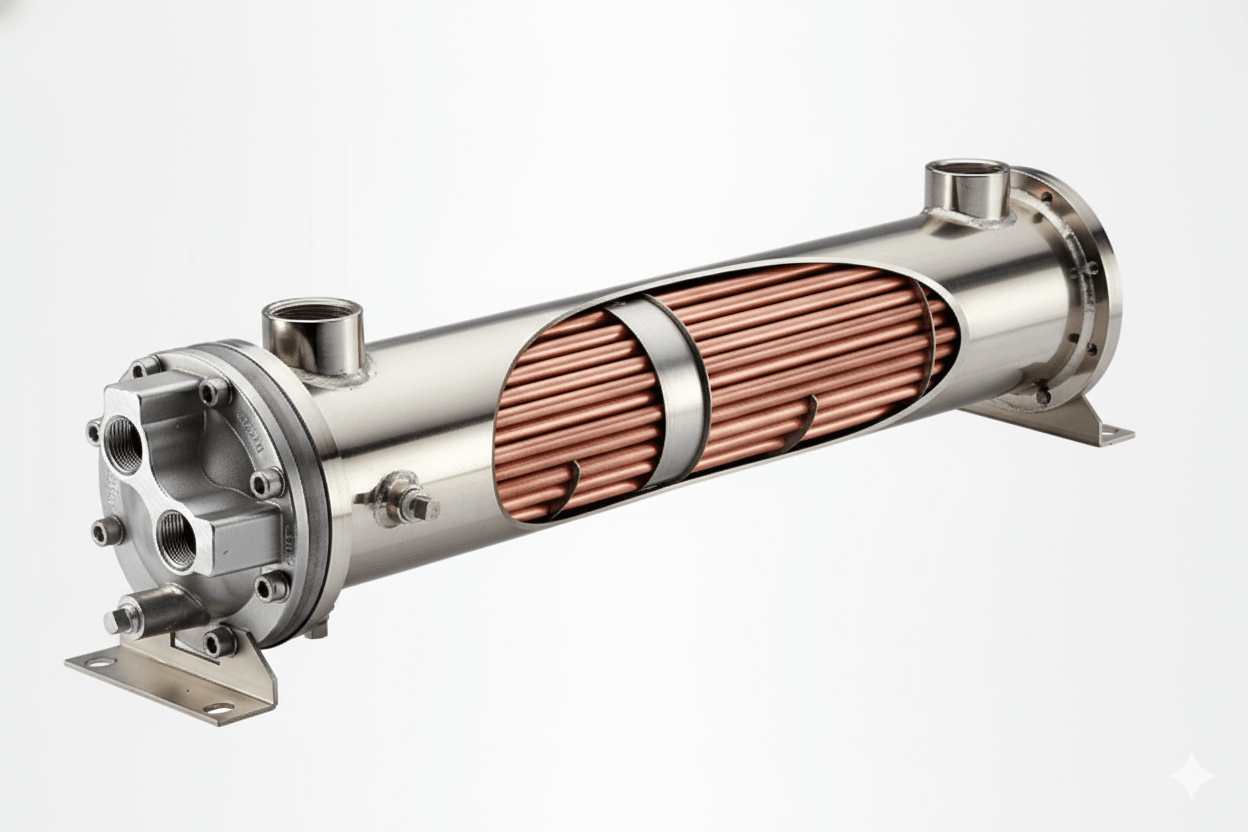

Material selection for both the fins and tubes is equally crucial. Copper and aluminum are common choices. Copper tubes offer excellent thermal conductivity and corrosion resistance, while aluminum fins are lightweight and cost-effective. The combination of copper tubes and aluminum fins, often called a Cu-Al design, provides a good balance of performance and cost, making it a popular choice for many data center applications.

2. Hybrid Cooling Solutions: Integrating Finned Tube Technology with Evaporative Systems for Optimal Efficiency

A hybrid cooling solution combines the advantages of both dry coolers and evaporative systems to achieve optimal efficiency. These systems typically use a dry cooler for sensible cooling when ambient temperatures are low enough, a practice known as “free cooling.” When temperatures rise, they introduce a water spray or evaporative pad to boost cooling efficiency. This approach leverages the energy savings of dry cooling most of the time, only using the more water-intensive evaporative cooling when absolutely necessary. The finned tube technology in these hybrid systems must be robust enough to handle both dry and wet operating conditions without a significant drop in performance or lifespan.

The push for energy efficiency is a constant driver of innovation in the data center industry. Copper-aluminum finned tube heat exchangers are a popular choice for next-generation data centers due to their superior performance. The high thermal conductivity of copper tubes allows for highly efficient heat removal from the liquid coolant, while the lightweight aluminum fins provide a large, cost-effective surface for transferring that heat to the air. By optimizing the design, manufacturers can create highly efficient heat exchangers that significantly reduce the overall energy consumption of the cooling system, leading to a lower total cost of ownership.

3. Comparing Performance of Different Fin Types in High-Ambient Temperature Environments

The shape and type of fins can significantly impact a dry cooler’s performance, especially in high-ambient temperature environments. Common fin types include flat plate fins, corrugated fins, and spiral fins. Corrugated fins create turbulence in the airflow, which enhances heat transfer and makes them particularly effective. Louvered fins are another advanced type that directs airflow more precisely, further improving performance. When operating in hot conditions, the choice of fin type, along with optimal fin density, is critical for achieving the necessary heat rejection without an excessive increase in fan power.

Free cooling is a strategy that uses cool ambient air to directly or indirectly cool a data center, drastically reducing energy consumption. Finned tube heat exchangers are central to indirect free cooling systems, where cool ambient air chills a fluid (like water or a glycol mixture) that is then circulated to the data center’s cooling units. Key design considerations for these applications include maximizing the heat exchange surface area to allow for effective cooling at low temperature differences and ensuring the materials can withstand seasonal temperature fluctuations and outdoor environmental conditions.

4. The ROI of Premium Finned Tube Heat Exchangers: A Total Cost of Ownership Analysis

While premium finned tube heat exchangers may have a higher initial cost, a total cost of ownership (TCO) analysis often shows a strong return on investment (ROI). The enhanced efficiency of these premium units leads to lower energy consumption, which can result in substantial operational savings over the lifespan of the data center. Furthermore, their superior materials and construction can lead to greater reliability and a longer operational life, reducing maintenance and replacement costs. A TCO analysis provides a holistic view, demonstrating that investing in high-quality components is more economical in the long run.

High-density computing racks demand an unprecedented level of cooling. Advanced finned tube technology is being developed to meet these requirements. Innovations include microchannel fin designs that increase surface area without a corresponding increase in pressure drop, as well as new fin geometries that improve air distribution. These advancements allow dry coolers to reject more heat in a smaller footprint, making them suitable for the unique challenges posed by high-density data centers.

Edge data centers are often deployed in non-traditional locations with challenging environmental conditions, from high dust to extreme temperatures. This requires custom finned tube solutions specifically engineered to withstand these environments. For example, wider fin spacing might be used to prevent fouling in dusty areas, while specialized coatings can be applied to resist chemical corrosion. These custom designs ensure the cooling system remains reliable and efficient regardless of its location.

5. Anti-Corrosion Finned Tube Technologies for Coastal Data Center Cooling Systems

Data centers located in coastal environments face a unique challenge: the corrosive effects of salt spray. This highly corrosive atmosphere can rapidly degrade the metallic fins and tubes of a heat exchanger, leading to decreased performance and premature failure. Anti-corrosion finned tube technologies are essential for these locations. This includes the use of specialized coatings, such as epoxy or electro-deposition coatings, on both the fins and tubes, and the selection of inherently corrosion-resistant materials. These technologies protect the heat exchanger from the harsh environment, ensuring a long and reliable operational life.

Conclusion

The choice between dry coolers and cooling towers for data centers is not a one-size-fits-all decision. It depends on a variety of factors, including climate, water availability, and the specific cooling demands of the facility. While cooling towers offer high efficiency through evaporation, dry coolers provide a compelling solution by eliminating water consumption, which is a significant operational and environmental benefit. The continued evolution of finned tube technology is central to this. Innovations in fin design, material science, and anti-corrosion treatments are making dry coolers increasingly viable for a wider range of applications, including high-density computing and challenging environmental conditions. The development of hybrid systems further blurs the line, allowing data center operators to leverage the best of both worlds, achieving optimal efficiency and sustainability. Ultimately, the future of data center cooling will likely be a mix of these technologies, with each being deployed in the most strategic way possible to maximize performance and minimize environmental impact.