Finned tube systems have long been the backbone of hydronic heating, but modern architectural demands have pushed them far beyond simple functionality. Today’s systems are no longer just about heat transfer; they are sophisticated, custom-engineered solutions that must integrate seamlessly with a building’s design. At the heart of this evolution are custom finned tube solutions, where the choice of materials is a critical factor influencing both energy efficiency and long-term lifespan. This article explores how material selection and design innovation are transforming finned tubes from a utilitarian component into an essential element of modern building design.

The Architect’s Guide to Integrating Modern Finned Tube Enclosures in Contemporary Building Design

For architects, the challenge is to incorporate heating systems without compromising aesthetic vision. The new generation of modern finned tube enclosures offers a solution. Unlike their clunky predecessors, these enclosures are sleek, low-profile, and can be customized to blend with a building’s interior. The architect’s guide to integrating them involves considering factors like color, texture, and profile. A well-designed enclosure can disappear into a wall or become a subtle design feature, providing efficient perimeter heating while maintaining the clean lines of a contemporary space. This integration proves that heating can be both effective and visually appealing.

Many modern buildings feature non-traditional layouts, such as curved walls, unique angles, or expansive glass facades. These spaces require heating solutions that go beyond standard dimensions. Custom engineering finned tubes is a necessity in these challenging architectural spaces. By tailoring the length, height, and even the curvature of the finned tubes and their enclosures, engineers can ensure even heat distribution in areas where standard baseboard heaters would be impractical or ineffective. This bespoke approach ensures that no matter the complexity of the design, the heating system can provide uniform comfort.

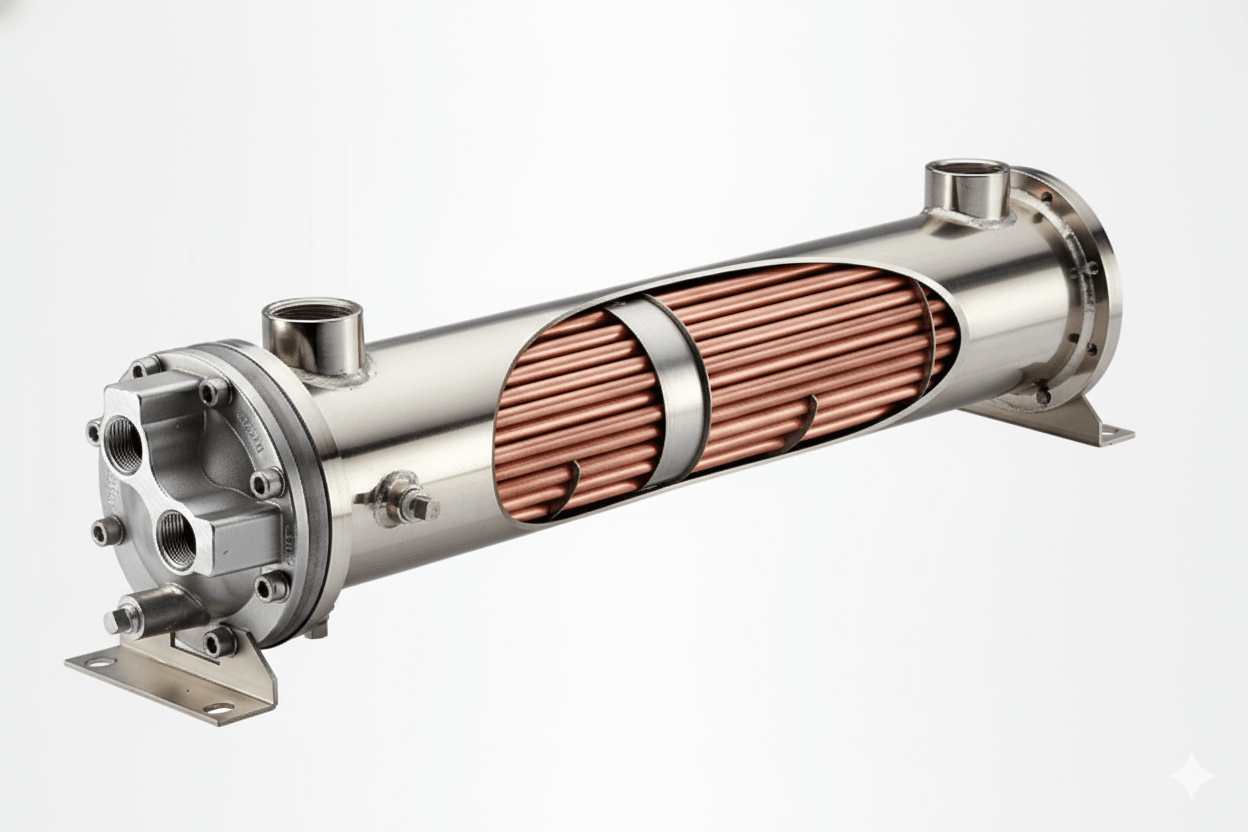

Comparing Aluminum-Finned vs. Steel-Finned Tube Performance in Commercial Heating Applications

The choice between fin materials significantly affects performance. Comparing aluminum-finned vs. steel-finned tube performance reveals distinct characteristics. Aluminum fins, with their superior thermal conductivity, are excellent for quick heat transfer and are often used in systems that require rapid response to temperature changes. Steel fins, while less thermally conductive, are more durable and can withstand harsh commercial environments. Each material has a specific place in commercial heating applications, and the selection depends on the project’s priorities—whether it’s maximum efficiency or rugged longevity.

The installation of a heating system is just as important as the design itself. For multi-row finned tube systems, proper installation is crucial for maximizing performance. Installation best practices include ensuring adequate spacing for airflow, correct alignment of the tubes, and a secure connection to the hydronic loop. A poorly installed system, even with high-quality components, will not deliver its designed BTU output. Following a detailed installation guide ensures the system operates at its peak efficiency, delivering consistent, reliable heat.

The Aesthetics of Efficiency: How Modern Finned Tube Enclosures Enhance Building Interiors

Finned tubes are no longer just hidden away. Modern finned tube enclosures are designed to be an integral part of a building’s interior, and their aesthetic appeal is a major selling point. They can be finished in a variety of colors and materials, from classic white to brushed stainless steel, allowing them to complement any design scheme. This focus on the aesthetics of efficiency shows that a building can be both an energy-efficient machine and a beautiful work of art, with the heating system playing a key role in the overall design.

For building owners looking to improve energy performance, a retrofit is a viable and often necessary option. Replacing outdated perimeter heating systems with advanced finned tube technology can dramatically increase a building’s efficiency. The new systems can be integrated with modern boilers or heat pumps, which operate at lower temperatures, leading to significant energy savings. This strategic upgrade can revitalize an older building, making it more comfortable, efficient, and appealing to modern occupants.

Engineering Guide: Selecting Optimal Fin Spacing and Size for Different Commercial Building Zones

Engineers must meticulously plan a heating system to ensure it meets the specific needs of each area of a building. This requires a detailed engineering guide for selecting optimal fin spacing and size. A large, open lobby with high ceilings may require a different fin configuration than a small, enclosed office. Factors like heat loss calculations, air flow patterns, and occupant comfort levels all influence the ideal fin design for a given zone. This customized approach guarantees the heating system is as efficient and effective as possible.

When budgeting for a new project, there is always a choice between standard and premium components. A cost-benefit analysis of premium vs. standard finned tube enclosures shows that the higher upfront cost of premium models is often justified by long-term benefits. Premium materials are more durable, have a longer lifespan, and offer better performance, leading to lower maintenance costs and greater energy savings over the life of the building. This makes the investment in quality a smart financial decision in the long run.

Architectural Finned Tube Enclosures: Balancing Form and Function in Modern Building Design

The ultimate goal of modern finned tube design is to achieve a perfect balance between form and function. Architectural finned tube enclosures are a prime example of this. They must provide excellent heat transfer while simultaneously enhancing the building’s interior. This balance is achieved through careful design and a commitment to quality. The best enclosures are not just an afterthought but a planned element that contributes to the overall aesthetic and performance of the space.

Specifying custom systems can be complex. A comprehensive guide for engineers and architects is essential for the process of specifying custom finned tube systems. This guide should cover everything from initial heat load calculations to material selection, aesthetic considerations, and installation details. By providing a clear, step-by-step process, this resource ensures that all project requirements are met, and the final product is exactly what the design team envisioned.

Irregular building layouts present unique installation challenges. Standard components may not fit, and on-site modifications can be costly and time-consuming. However, by using a custom approach, these challenges can be overcome. Adapting finned tube systems to fit these spaces is where the true value of custom engineering shines. Manufacturers can pre-fabricate components to the exact specifications of a project, simplifying installation and reducing labor costs.

The Evolution of Commercial Finned Tube Technology: From Basic Heating to Architectural Statement

The journey of commercial finned tube technology is one of continuous evolution. What began as a simple, hidden heating element has transformed into a sophisticated, highly-engineered product. The shift is from a purely functional object to an architectural statement—a component that contributes to both the performance and the aesthetic of a modern building. This evolution is driven by the demand for greater efficiency, customization, and design integration, pushing the boundaries of what is possible in building systems.