When it comes to designing heat exchangers or cooling systems, maximizing heat transfer is essential for efficiency and performance. Both fins and tubes play crucial roles in heat exchangers, each serving a specific function that impacts heat transfer effectiveness. Understanding which is better for heat transfer—fins or tubes—depends on the application and design requirements. In this guide, we’ll break down the role of fins and tubes, their respective heat transfer properties, and which is better for specific scenarios.

“In heat transfer systems, tubes serve as the main channels for fluid and primary heat exchange surfaces, while fins improve efficiency by increasing surface area, making fins ideal for systems requiring high heat dissipation in compact spaces.” Selecting fins or tubes depends on system requirements, such as space constraints, efficiency needs, and pressure conditions.

Understanding the Role of Tubes in Heat Transfer

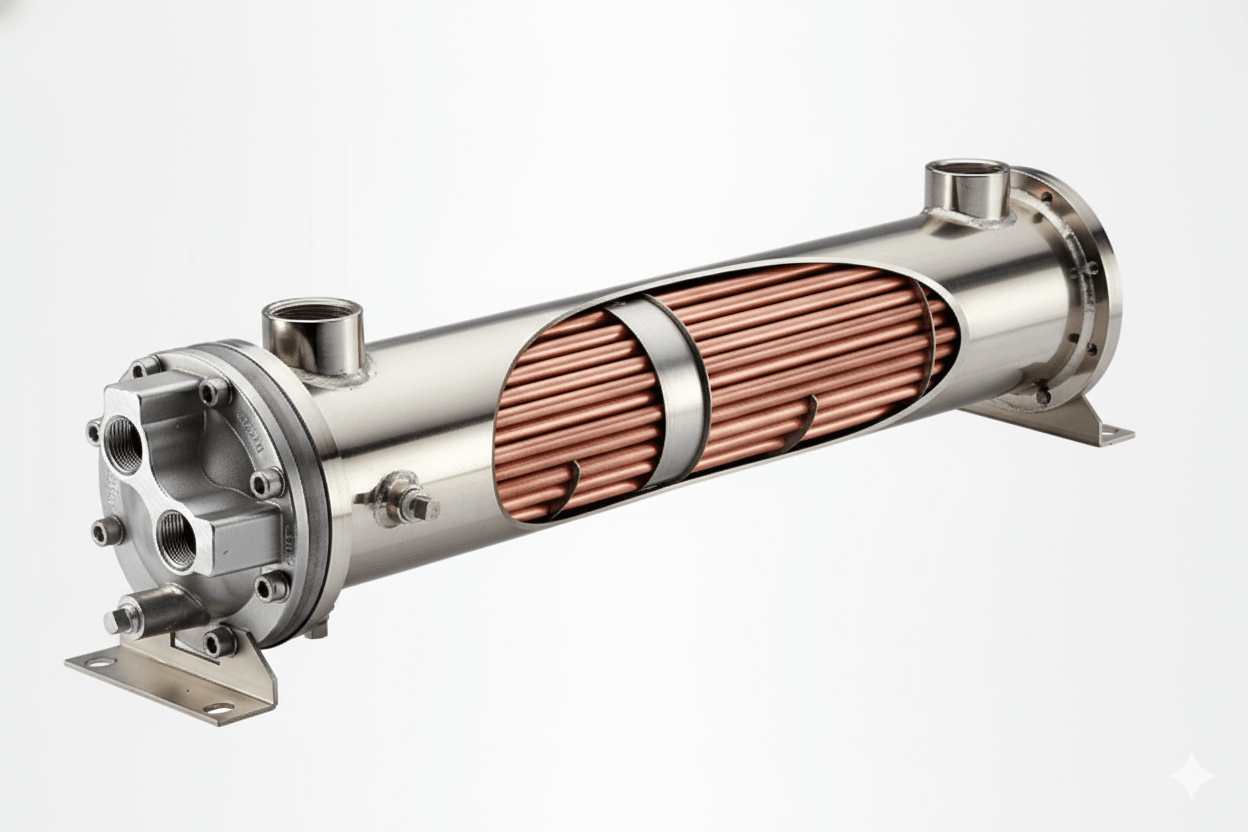

Tubes are cylindrical channels that carry fluid through a heat exchanger, allowing for direct heat transfer between the fluid and the tube walls. They act as the primary pathway for fluid flow and are essential for moving heat from one part of a system to another. Tubes are commonly found in shell-and-tube heat exchangers, radiators, condensers, and evaporators, where they provide the main surface for heat exchange.

Key Benefits of Tubes for Heat Transfer

- Direct Heat Transfer: Tubes allow direct heat transfer between the fluid inside the tube and the surrounding environment, making them ideal for high-flow and high-pressure applications.

- Material Conductivity: Tubes are often made from thermally conductive metals like copper or aluminum, allowing efficient transfer of heat.

- Versatility and Durability: Tubes are suitable for high-pressure environments due to their straightforward design, making them versatile in various industrial applications.

When Tubes Excel in Heat Transfer

Tubes are best for applications where high pressure, durability, and straightforward heat transfer are necessary. In large-scale systems with substantial fluid flow, like boilers and condensers, tubes effectively facilitate heat transfer. However, bare tubes alone may not always be the best choice for systems where space is limited or heat transfer needs to be maximized in a compact design.

The Function of Fins in Enhancing Heat Transfer

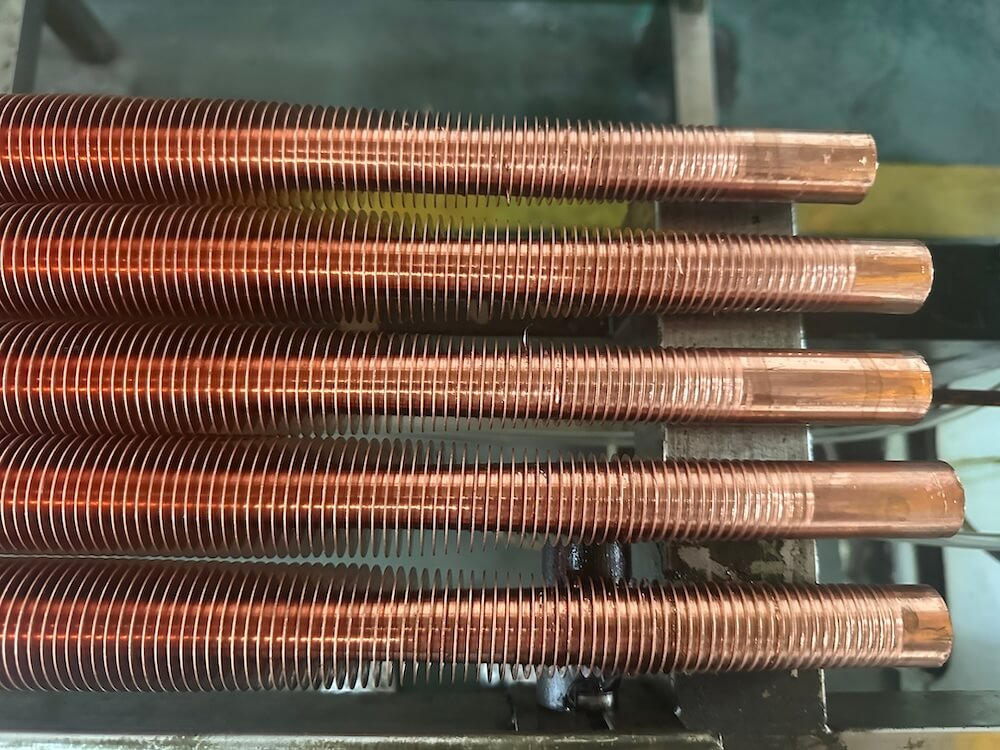

Fins are thin, extended surfaces added to the outside of tubes or other heat transfer surfaces. The primary role of fins is to increase the surface area available for heat exchange, allowing for quicker and more efficient heat dissipation. By enhancing the tube’s ability to release or absorb heat, fins improve the overall efficiency of a cooling or heating system. Fins are common in applications where space is limited but high heat dissipation is required, such as in radiators, HVAC systems, and electronics cooling.

Key Benefits of Fins for Heat Transfer

- Increased Surface Area: Fins create additional surface area around the tube, allowing for faster heat exchange with the surrounding environment.

- Improved Efficiency in Compact Spaces: Fins are ideal in systems where space is tight but high heat transfer efficiency is needed, as they provide effective heat dissipation without increasing tube size.

- Lightweight and Customizable: Fins can be designed in various shapes, such as straight, spiral, or helical, to maximize efficiency based on specific requirements.

When Fins Excel in Heat Transfer

Fins are ideal for applications where a system requires efficient heat transfer in a small footprint. In systems like car radiators, HVAC coils, and computer cooling systems, fins allow heat to be dissipated quickly without adding bulk. However, they are best suited for low- to moderate-pressure environments, as high pressures could damage the fins.

Comparing Heat Transfer Efficiency: Fins vs. Tubes

When deciding between fins and tubes for optimal heat transfer, it’s essential to consider factors like surface area, flow efficiency, and system requirements.

1. Surface Area and Contact

The surface area is a key factor in heat transfer efficiency, as a larger area allows for more heat exchange.

- Tubes: Bare tubes have a limited surface area. While they work well in systems with large volumes of fluid, they may not dissipate heat as effectively without additional surface area.

- Fins: By adding fins to a tube, the surface area is significantly increased, allowing more heat to be transferred in a shorter time. Fins make heat exchangers more efficient without requiring larger tubes.

In systems where space is limited but high heat transfer is needed, fins offer an advantage by increasing the heat exchange surface area while keeping the design compact.

2. Flow and Pressure Efficiency

Pressure tolerance and fluid flow rates are also critical when choosing between fins and tubes.

- Tubes: Tubes alone can handle high pressure and high fluid flow, making them suitable for heavy-duty systems like boilers or industrial heat exchangers. Their design provides a direct path for fluid flow without added resistance.

- Fins: Fins can increase airflow resistance, potentially causing a slight drop in pressure. This may be a disadvantage in high-pressure systems but is generally manageable in low- to medium-pressure applications where the primary goal is heat dissipation rather than fluid flow.

In industrial applications where pressure is a concern, bare tubes may be more suitable, while fins are advantageous in moderate-pressure, compact systems.

3. Energy and Cost Efficiency

Energy consumption and cost are also important considerations in heat exchanger design.

- Tubes: Since bare tubes require more fluid flow to achieve efficient heat transfer, they may consume more energy. However, they are typically simpler and cost-effective to produce and maintain, especially in industrial settings.

- Fins: Fins increase heat transfer efficiency, allowing systems to operate at lower flow rates, reducing energy use. Although adding fins can increase manufacturing costs, the overall operational savings make finned tubes more cost-effective in applications where energy efficiency is a priority.

For systems with limited energy resources or a focus on cost savings, fins provide a greater heat transfer efficiency, making them an economical choice in the long term.

Practical Applications of Fins and Tubes in Heat Transfer

Choosing between fins and tubes depends on the system’s design requirements. Here are some practical applications where each excels:

Best Applications for Bare Tubes

- High-Pressure Systems: Bare tubes are more suited for high-pressure applications due to their simple, durable design. They are widely used in industrial boilers, large condensers, and shell-and-tube heat exchangers.

- Large-Volume Flow Systems: Bare tubes work efficiently in systems with high fluid flow, where pressure tolerance and flow are more important than compactness.

- Heavy-Duty Industrial Use: For applications where maintenance is frequent and fouling occurs, bare tubes are easy to clean and replace, making them a reliable option.

Best Applications for Finned Tubes

- Compact, High-Efficiency Systems: Finned tubes are ideal for applications where space is limited, but high heat transfer efficiency is required, like in HVAC systems, automotive radiators, and electronic cooling.

- Low to Moderate Pressure Systems: In systems that don’t operate under high pressure, finned tubes are ideal for efficient heat dissipation without needing larger tubes or additional components.

- Energy-Conscious Applications: Finned tubes reduce energy consumption due to their high heat transfer rates, making them suitable for green building designs, energy-efficient appliances, and systems that prioritize sustainability.

Final Verdict: Which is Better for Heat Transfer?

The answer to whether fins or tubes are better for heat transfer depends on the specific requirements of the application. Fins excel in increasing heat transfer efficiency in compact, low-pressure systems by maximizing surface area, making them ideal for applications where space and energy savings are essential. On the other hand, bare tubes are more suitable for high-pressure systems with large fluid volumes and straightforward heat transfer needs, such as in industrial heat exchangers or systems requiring durability.

Summary: Fins improve heat transfer by increasing surface area, ideal for compact and efficient designs, while bare tubes are better for high-pressure, high-flow applications where simplicity and durability are key. Knowing these differences can help optimize heat exchanger performance based on specific system requirements.

Selecting the right combination of fins and tubes based on the system’s unique demands can lead to greater efficiency, energy savings, and overall performance, ensuring a well-functioning heat transfer system tailored to your needs.