Finned copper tube heat exchangers are widely used in heating, ventilation, and air conditioning (HVAC) systems, as well as in swimming pool heaters, refrigeration, and industrial equipment. Known for their efficiency in transferring heat, these heat exchangers play a critical role in regulating temperatures across various systems. In this article, we’ll explore how finned copper tube heat exchangers work, their benefits, and their applications.

“A finned copper tube heat exchanger works by increasing the surface area of the copper tubing with fins, allowing for rapid and efficient heat transfer between two media, like air and water.” This design maximizes heat exchange while maintaining a compact form, making it a popular choice for diverse heating and cooling systems.

What is a Finned Copper Tube Heat Exchanger?

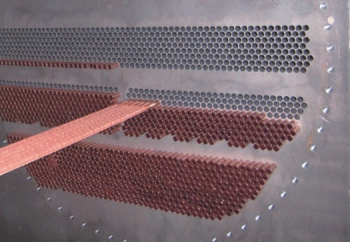

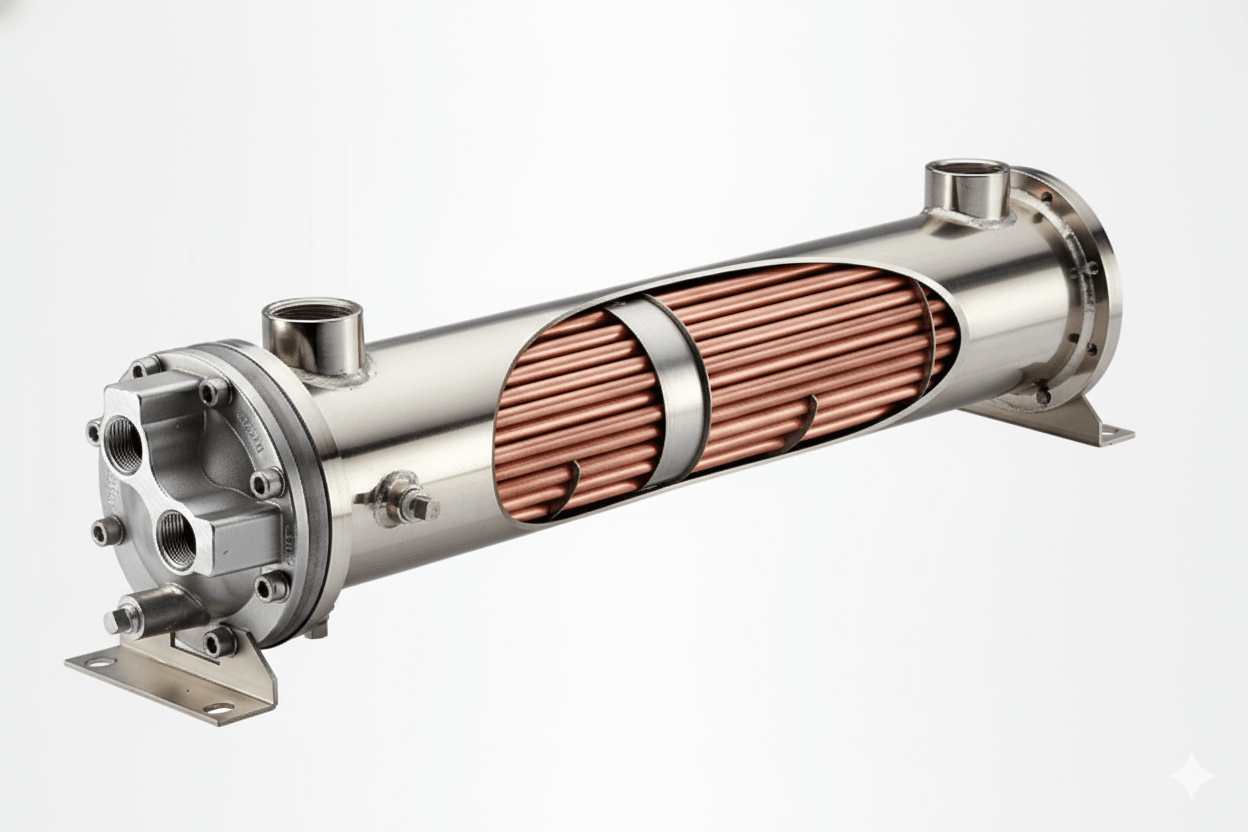

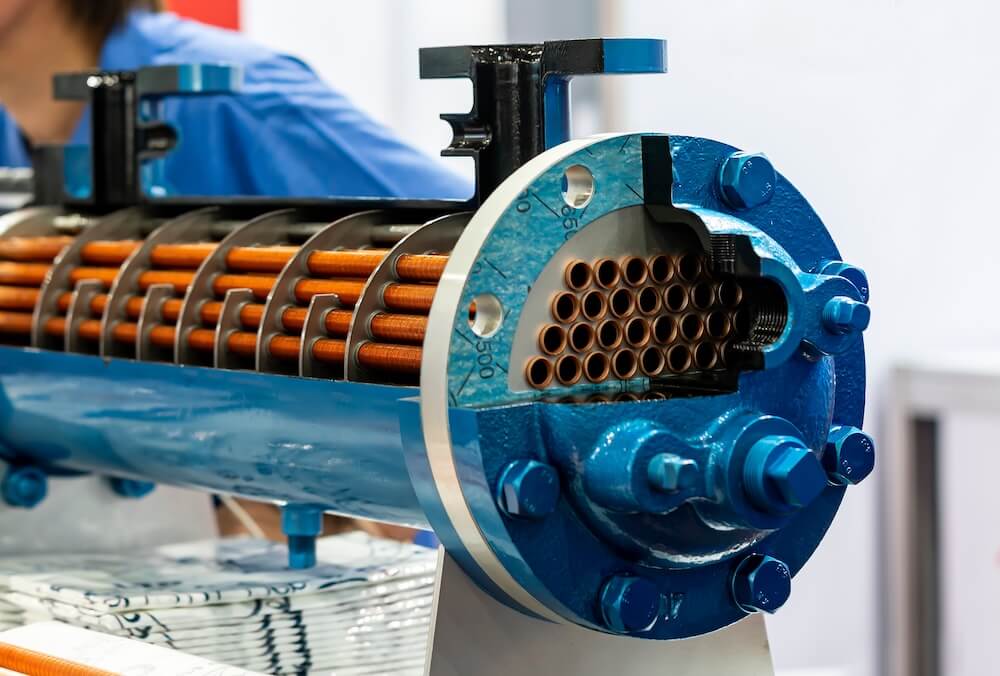

A finned copper tube heat exchanger is a type of heat exchanger that consists of copper tubes with fins attached to the outer surface. Copper is an excellent conductor of heat, and by adding fins, the surface area is significantly increased, allowing for faster and more efficient heat transfer. These fins are usually made of aluminum or copper and are spaced evenly along the tube to ensure uniform heat distribution.

The primary purpose of a finned copper tube heat exchanger is to transfer heat from one medium to another. In HVAC and pool systems, for example, heat exchangers allow hot or cold air or water to pass over the fins, warming or cooling the medium efficiently as it flows through the system.

How Finned Copper Tube Heat Exchangers Work

The design and functionality of a finned copper tube heat exchanger are relatively straightforward, but it’s this simplicity that makes them so effective. Here’s a step-by-step breakdown of how these heat exchangers work:

1. Heat Absorption Through the Copper Tubes

The process begins as a hot or cold fluid, typically water or refrigerant, flows through the copper tube. Copper has high thermal conductivity, which allows it to absorb or release heat quickly. When hot water or another heated fluid flows through the copper tube, the heat transfers from the fluid to the copper, warming the tube.

2. Heat Transfer Amplified by Fins

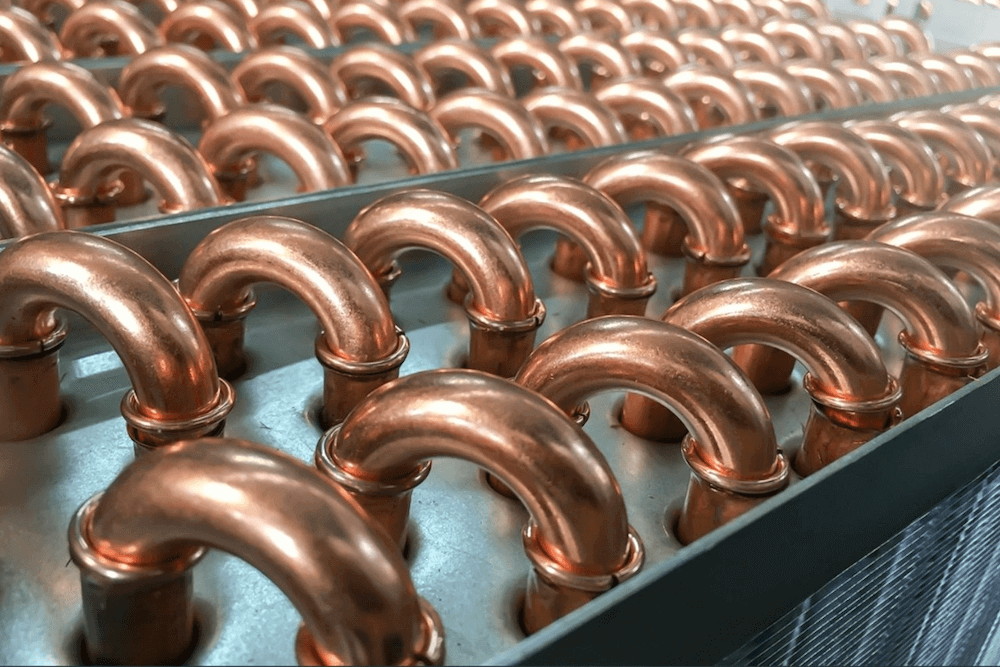

As the copper tube warms up, the fins attached to the tube also start to heat up. The fins serve a critical purpose: by increasing the surface area of the tubing, they provide more space for heat to transfer from the tube to the surrounding air or liquid. This large surface area allows for rapid and efficient heat exchange.

3. Cooling or Heating the Surrounding Medium

With the fins acting as an extension of the copper tube, heat is either released into the surrounding air or liquid or absorbed from it. For instance, in an air conditioning unit, cool refrigerant running through the copper tube absorbs heat from the surrounding air, cooling the air before it’s distributed through a building. In a heating system, hot water inside the tube releases heat to warm the surrounding air, which can then be circulated throughout a space.

4. Continuous Heat Exchange Cycle

The heat exchanger operates as a continuous loop, with fluid circulating through the copper tubing and fins absorbing or releasing heat as needed. This ongoing cycle ensures a stable temperature, whether it’s heating, cooling, or maintaining a consistent temperature in a given system.

Benefits of Using Finned Copper Tube Heat Exchangers

Finned copper tube heat exchangers offer numerous advantages, making them an excellent choice in various applications. Here’s why they’re so popular:

1. High Thermal Efficiency

Copper’s high thermal conductivity combined with the added surface area of fins enables efficient and rapid heat transfer. This efficiency allows systems to reach desired temperatures faster and maintain them more consistently, which can reduce energy consumption and operational costs.

2. Compact Design

The finned design of these heat exchangers allows for a high heat transfer rate in a relatively small space. This makes finned copper tube heat exchangers ideal for systems where space is limited, such as compact HVAC units or portable pool heaters.

3. Corrosion Resistance and Durability

Copper is naturally resistant to corrosion, which is crucial for long-term operation in systems that involve water or humid air. When maintained properly, finned copper tube heat exchangers can last for years without significant degradation, making them a durable and cost-effective option.

4. Versatility Across Applications

From residential air conditioning systems to industrial machinery, finned copper tube heat exchangers are versatile and suitable for a wide range of applications. Their ability to handle both heating and cooling makes them adaptable to multiple environments and system requirements.

Applications of Finned Copper Tube Heat Exchangers

Finned copper tube heat exchangers are versatile and adaptable, commonly found in various settings that require efficient temperature control. Here are a few key applications:

1. HVAC Systems

In HVAC (Heating, Ventilation, and Air Conditioning) systems, finned copper tube heat exchangers are used to regulate indoor air temperatures. The heat exchangers transfer heat between indoor and outdoor air, helping to cool or heat buildings quickly. In air conditioning, for example, they facilitate the cooling process by efficiently removing heat from the air before it’s redistributed indoors.

2. Pool Heaters

Finned copper tube heat exchangers are commonly used in swimming pool heaters, where they transfer heat from a fuel source, like natural gas, to the pool water. The increased surface area allows these heat exchangers to raise water temperatures quickly, making them a preferred option for residential and commercial pools.

3. Refrigeration Units

In refrigeration, finned copper tube heat exchangers play a vital role in absorbing and releasing heat, which is necessary for maintaining cold temperatures. The efficient heat exchange process helps refrigeration units reach and sustain low temperatures, keeping food and other items fresh.

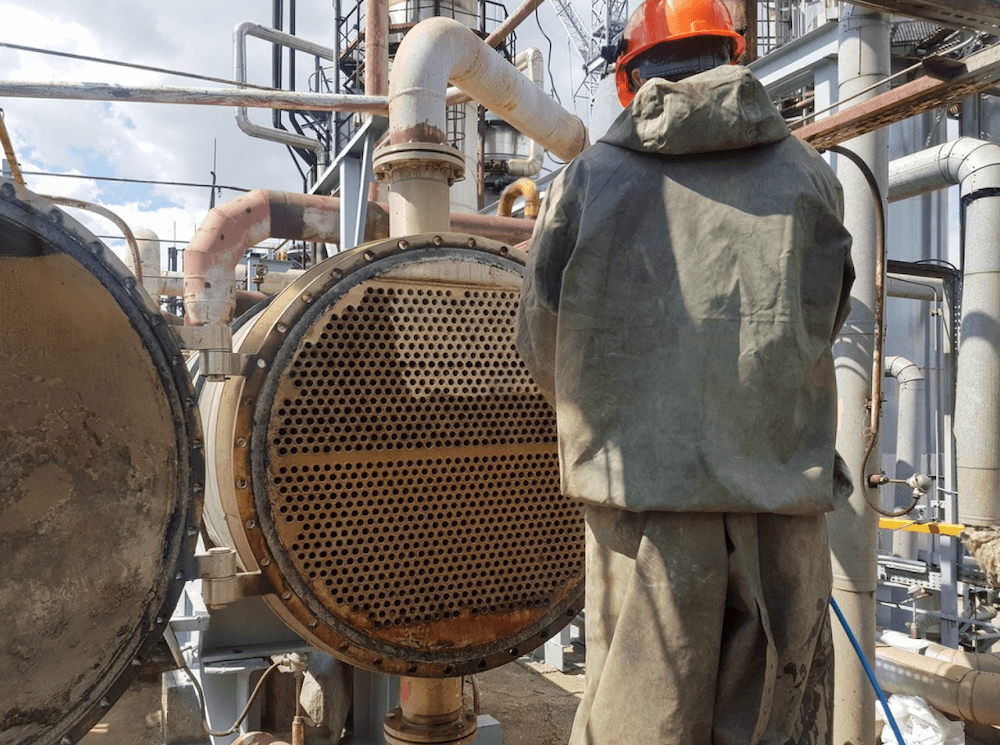

4. Industrial Heat Exchangers

Many industrial systems, such as boilers, chemical processing units, and manufacturing machinery, use finned copper tube heat exchangers to maintain stable temperatures during production processes. The heat exchangers regulate temperatures, helping to protect machinery from overheating and ensuring safe operation.

Maintenance Tips for Finned Copper Tube Heat Exchangers

To keep finned copper tube heat exchangers operating efficiently, regular maintenance is essential. Here are some key maintenance tips:

1. Regular Cleaning

Over time, dust, dirt, and debris can accumulate on the fins, reducing their ability to transfer heat effectively. Clean the fins and tubing periodically with compressed air or a soft brush, taking care not to bend the fins.

2. Check for Corrosion

Even though copper is corrosion-resistant, exposure to certain chemicals or harsh environmental conditions can still cause corrosion. Inspect the tubing regularly for any signs of wear or corrosion and address these issues immediately.

3. Monitor for Leaks

Small leaks in the copper tubing can compromise the efficiency of the heat exchanger. Routinely check for leaks, especially if there are signs of water pooling or a drop in system performance.

4. Ensure Proper Airflow

Blocked or restricted airflow around the fins can impact performance. Keep the area around the heat exchanger clear and make sure nothing obstructs the fins or tubing.

Final Thoughts

Finned copper tube heat exchangers are an essential component in many heating and cooling systems, providing efficient temperature control through enhanced heat transfer. By increasing the surface area of copper tubing, these heat exchangers enable faster heating and cooling, which is crucial for applications ranging from residential HVAC systems to industrial equipment.

Summary: A finned copper tube heat exchanger works by transferring heat through copper tubing with extended fins, providing rapid and efficient heat transfer between two media. With benefits like high thermal efficiency and corrosion resistance, it’s a versatile choice for HVAC, pool heaters, refrigeration, and industrial systems.

By understanding how finned copper tube heat exchangers function and following proper maintenance practices, you can ensure optimal performance and long-term durability for any system that relies on effective temperature control.