Removing aluminum fins from copper tubing is a task that comes up frequently in HVAC, refrigeration, and heat exchange system maintenance. Whether you’re upgrading equipment, repairing heat exchangers, or salvaging copper tubing for recycling, understanding how to properly remove aluminum fins is essential to maintaining the integrity of the copper tube. This process requires the right technique and tools to avoid damaging the copper tube itself, as well as to ensure safety and efficiency.

In this blog, we’ll break down why you might need to remove aluminum fins from copper tubing, provide you with a step-by-step guide, and share important insights into making the process smooth and successful.

Why Remove Aluminum Fins from Copper Tubing?

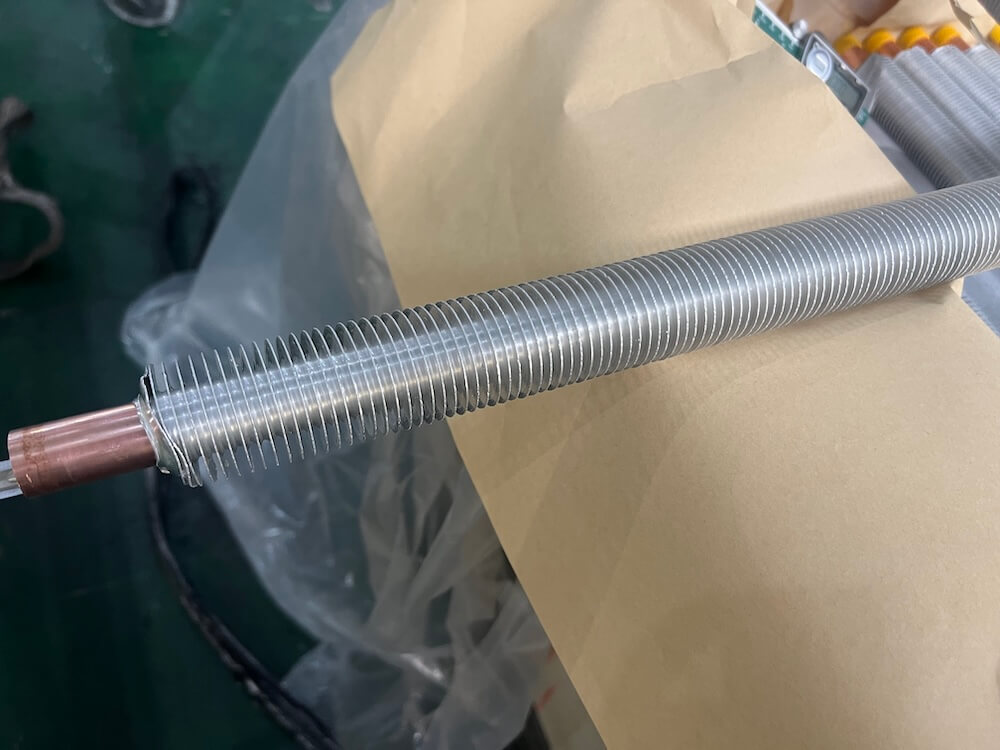

Aluminum fins are often used in heat exchangers, air conditioners, and refrigeration units. They are designed to increase the surface area for heat transfer, improving the efficiency of the system. However, over time, these aluminum fins can become damaged, corroded, or ineffective. In many cases, technicians may need to replace or remove the fins for several reasons:

- Replacement of damaged fins: Over time, aluminum fins can become bent, clogged, or corroded, reducing the efficiency of the system. Removing them allows you to replace or upgrade the fins to improve performance.

- Recycling copper tubing: If you are salvaging copper tubing for scrap, removing the aluminum fins is necessary to maximize the value of the copper.

- Upgrading equipment: In certain applications, you may need to replace old aluminum fins with more durable materials, such as copper fins, for better heat transfer performance.

Key Considerations Before Removing Aluminum Fins

Before you begin removing aluminum fins from copper tubing, there are a few things to consider:

- Tools and Equipment: Make sure you have the right tools to prevent damaging the copper tubing. Copper is a soft metal and can be easily scratched or deformed if handled incorrectly.

- Safety: Wear safety gloves and goggles to protect yourself from sharp aluminum edges and debris during the process. Aluminum fins can have sharp edges, and you want to avoid injury while working.

- Work Area: Ensure that you’re working in a well-lit, clean area where you can clearly see the aluminum fins and copper tubing. This will help you work more efficiently and safely.

How to Remove Aluminum Fins from Copper Tubing: A Step-by-Step Guide

Now, let’s dive into the process. Here’s a detailed step-by-step guide to removing aluminum fins from copper tubing:

Step 1: Prepare Your Tools

The first step in removing aluminum fins is to gather the proper tools. You’ll need:

- Utility knife or razor blade: For cutting through the aluminum fins.

- Needle-nose pliers: To grip and peel the fins away from the tubing.

- Flathead screwdriver: Can be helpful for prying off any stubborn fins.

- Hammer: In some cases, a gentle tap with a hammer can help loosen the fins if they are particularly tight.

- Safety gloves and goggles: To protect your hands and eyes from sharp edges.

Step 2: Cut the Aluminum Fins (if necessary)

Sometimes, aluminum fins are tightly wrapped around copper tubes, and simply pulling them off may not be possible. In such cases, you’ll need to use a utility knife or razor blade to cut through the fins.

- Begin by carefully scoring the aluminum fin material. Work in small sections, cutting vertically along the fin to create an opening.

- Take care not to cut into the copper tubing itself. A shallow cut along the aluminum will usually be sufficient to weaken the connection between the fin and the tube.

- After scoring the fin, you can use your pliers or flathead screwdriver to begin prying the aluminum fin off the copper tubing.

Step 3: Peel the Aluminum Fins Off

Once the fins are scored, the next step is to peel them off the copper tubing. You can do this by gently pulling with needle-nose pliers.

- Grip the fin at one end and slowly work your way along the length of the tubing. The goal is to avoid pulling too hard, as this could damage the copper tube.

- If the fins are stuck or difficult to remove, you can use a flathead screwdriver to loosen them further. Gently pry between the fin and the copper tubing to help break the bond.

- For more stubborn fins, a gentle tap with a hammer on the pliers can help break the bond between the fin and tube. But be cautious not to damage the copper tubing with excessive force.

Step 4: Remove the Remaining Residue

Once the majority of the aluminum fins have been removed, there may still be small pieces or adhesive residue left behind. To clean these off:

- Use a wire brush or a scraping tool to carefully remove any remaining aluminum debris or adhesive.

- For more stubborn residue, a small amount of acetone or rubbing alcohol can be used to clean the copper tubing. Be sure to thoroughly rinse the tubing afterward to ensure all cleaning agents are removed.

Step 5: Inspect the Copper Tubing

After you’ve successfully removed all aluminum fins, it’s important to inspect the copper tubing. Look for any signs of damage, such as deep scratches, dents, or bends, as this could affect the performance of the tubing if you plan to reuse it.

If the copper tubing is in good condition, it’s ready for reuse. If there is damage, it may need to be replaced or repaired before it can be used in a new system.

Challenges and Solutions in Removing Aluminum Fins

While the process of removing aluminum fins from copper tubing is straightforward, there are some common challenges you may face. Let’s address a few of them:

- Stubborn fins: If the aluminum fins are difficult to remove, try heating them up with a heat gun. This can help loosen any adhesives or bonds between the fins and the copper tubing.

- Damaged copper tubing: Be cautious when removing aluminum fins. If you accidentally damage the copper tubing, it may no longer be usable for high-performance applications like heat exchangers. Use protective padding or tape around the tubing if necessary to avoid scratches or dents.

In Summary: Best Practices for Removing Aluminum Fins from Copper Tubing

Removing aluminum fins from copper tubing is a manageable task when done with the right tools and technique. Whether you’re working to replace damaged fins, salvage copper tubing, or upgrade your heat exchanger, the steps outlined above will help you get the job done safely and efficiently. Always prioritize safety, take your time to avoid damaging the copper, and use the proper tools to make the job easier.

In conclusion, removing aluminum fins from copper tubing is an important maintenance task that can help you restore or recycle your materials for reuse. By following the proper steps and using the right tools, you can efficiently remove aluminum fins without damaging the copper tubing itself. This will help improve the longevity and efficiency of your heat exchange systems or allow for a successful copper recycling process.

Writer’s extra words: if finally have to consider to remove aluminum fins from copper tubing, why not use direct 100% copper finned tube single material at beginning? Higher heat transfer efficiency and lasting quality than bimetal finned tubes, and no bother to peel the fins off when need recycle the raw materials years later. For our manufacturing factory, though the aluminum fins save material cost compared with copper finned tubes, but the production processing need one more step so higher labor cost. As both bi-metal finned tube and copper finned tubing manufacturer with many years experience, we would firstly recommend our customer copper fin tubes for sure. Welcome to contact us to consult any question about fin tubes, we’d like to add value for your business!