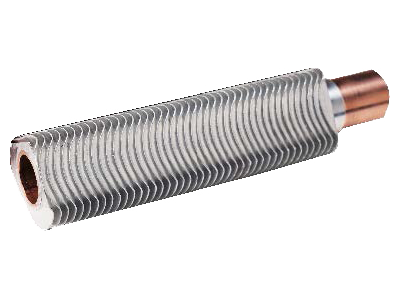

Bi-Metal Finned Tube

Bi-Metal Finned Tubes Supplier

China Bi-Metal Finned Tubes Manufacturer

We specialize in manufacturing a wide range of copper finned tubes, including integral finned tubes, extruded finned tubes, and bimetallic finned tubes. Our products are designed for various heat exchanger applications, such as condensers, evaporators, boilers, and chillers, ensuring efficient heat transfer and durability in demanding industries like HVAC, energy, and petrochemicals.

Technical Specification:

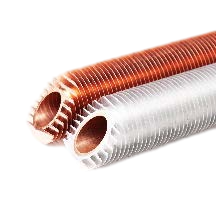

- Base Tube Material: Options include stainless steel, carbon steel, alloy steel, titanium, nickel, and copper.

- Fin Material: Typically aluminum or copper.

- Maximum Working Temperature: Ranges from 250°C to 300°C depending on the specific type of fin tube.

- Maximum processing length: 7m.

Main Application:

- Petroleum and Petrochemical: For cooling and heating processes in refineries.

- Power Generation: In heat recovery systems and steam generators.

- HVAC Systems: For efficient heating and cooling solutions in buildings.

Copper Finned Tube Parameter

| Code | Plain End | Plain End | Plain End | Finned Section | Finned Section | Finned Section | Finned Section | Nominal (m2/m) | Surface Area Ratio |

|---|---|---|---|---|---|---|---|---|---|

| CTHF | Outside Diameter(mm) | Inside Diameter(mm) | Nominal Wall(mm) | Outside Diameter(mm) | Fin Height (mm) | Min Wall Under Fins(mm) | Fin Per Inch(mm) | Ourside Surface Area | Outside to Inside |

| 39-19-7 | 19 | 16 | 1.5 | 39 | 9 | 1.6 | 7 | 0.535 | 10.64 |

| 45-23-7 | 23 | 19.8 | 1.6 | 45 | 10.5 | 1.7 | 7 | 0.704 | 11.32 |

| 46-25.9-5 | 25.9 | 22.4 | 1.75 | 46 | 9.5 | 1.85 | 5 | 0.535 | 7.6 |

| 47-25.9-7 | 25.9 | 22.4 | 1.75 | 47 | 10.5 | 1.85 | 7 | 0.75 | 10.65 |

| 48-25.4-7 | 25.4 | 22 | 1.7 | 48 | 10.5 | 1.8 | 7 | 0.76 | 11.13 |

What Is Bi-Metal Fin Tube?

Bi-metal fin tubes are specialized components used primarily in heat exchangers to enhance heat transfer efficiency. These tubes consist of two different metals, typically an inner base tube made from materials like copper, stainless steel or carbon steel, and an outer layer of aluminum that is finned through a process known as cold plastic deformation.

Advantages Of Bi-Metal Fin Tubes

Improved Heat Transfer: The design maximizes the surface area available for heat exchange, leading to enhanced thermal performance compared to traditional finned tubes.

Corrosion Resistance: The aluminum outer layer provides excellent corrosion protection for the base tube, extending the lifespan of the heat exchanger.

High Mechanical Strength: The extrusion process results in fins that are tightly bonded to the base tube, minimizing risks of detachment under thermal stress or vibration.

Versatility: These fin tubes can be used in a variety of applications, including air-cooled heat exchangers, boilers, and industrial waste heat recovery systems.

Manufacturing Process Of Bi-Metal Fin Tubes

1, Tube Preparation: An aluminum outer tube (often referred to as a muff) is aligned over an inner base tube.

2, Finning Process: Both tubes are pushed through mandrels equipped with rotating discs that exert high pressure, extruding the aluminum into fins that spiral outward from the muff. This process creates a strong mechanical bond between the aluminum fins and the inner tube, ensuring excellent thermal conductivity and structural integrity.

3, Fin Configuration: The fins can be designed in various configurations, including serrated or helical shapes, which further enhance heat transfer capabilities by increasing surface area and improving fluid dynamics around the fins.

Applications Of Bi-Metal Fin Tubes

Bi-metal extruded fin tubes are widely utilized across several industries due to their efficiency in heat exchange and durability. The most common industries that employ these specialized components include:

- Power Generation: Used extensively in electric, nuclear, thermal, and geothermal power plants for heat exchangers.

- Petroleum and Petrochemical: Essential in processes involving oil refining, gas treatment, and chemical production.

- Chemical Processing: Employed in systems such as condensers and evaporators, particularly in high-corrosive environments.

- Food Processing: Utilized in refrigeration and heating applications to ensure safe food handling and processing.

- HVAC Systems: Commonly found in air conditioning units and heat recovery systems to optimize energy use.

- Marine Applications: Suitable for seawater desalination and other offshore operations where corrosion resistance is crucial.

- Industrial Applications: Used in steel mills, incinerators, and gas compression facilities for efficient thermal management.

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

Mass Production Photos

Check how we will produce your finned tube bulk orders of in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Bi-Metal Fin Tubes For Heat Exchangers

What materials are used in the construction of your bi-metal fin tubes?

Our bi-metal fin tubes typically use a combination of aluminum fins and a copper or steel base tube. We also offer custom material combinations, such as copper-nickel, stainless steel, and titanium, depending on the application.

Can your bi-metal fin tubes be used in high-pressure environments?

What are the standard sizes and dimensions of your bi-metal fin tubes?

What industries typically use your bi-metal fin tubes?

Our bi-metal fin tubes are used in a variety of industries, including HVAC, petrochemical, power generation, oil and gas, refrigeration, and marine applications.

What is the lead time for ordering bi-metal fin tubes?

The standard lead time for bi-metal fin tubes is 4-5 weeks, depending on the order quantity and customization requirements. For urgent orders, we can arrange expedited production.

Do you provide certificates of quality or compliance for your bi-metal fin tubes?

Yes, we provide full documentation, including material test certificates (MTC), third-party inspection reports, and compliance certificates such as ISO 9001, ASME, and ASTM standards.

Can you design custom bi-metal fin tubes for specific heat exchanger applications?

Absolutely. We specialize in custom designs based on your heat exchanger requirements. Our engineering team will work with you to optimize the design for maximum efficiency and performance.

What is the maximum operating temperature for your bi-metal fin tubes?

Our bi-metal fin tubes can operate at temperatures up to 300°C, depending on the materials used. For higher temperature applications, we recommend stainless steel or copper-nickel tubes.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!