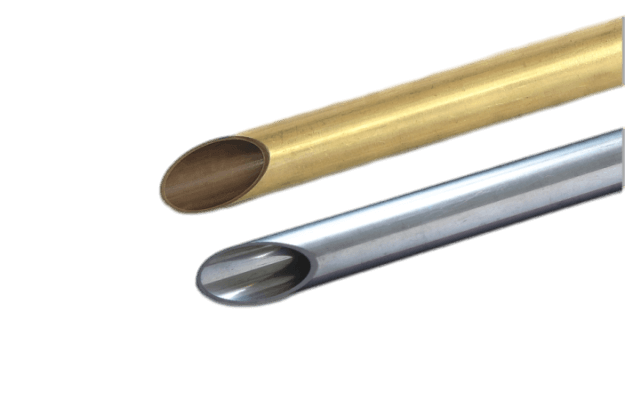

Copper Alloy Tube

China Copper Alloy Tubes Supplier

China Copper Alloy Tubes Supplier

Cufin Tube specializes in high-quality copper finned tubes and alloy solutions tailored for diverse industries. With over 300 product series and advanced machinery, we ensure competitive pricing and consistent quality. Partner with us to enhance your projects, whether in HVAC, oil and gas, or heat exchangers. Experience superior performance and exceptional service that sets us apart in the market!

Technical Specification:

- Copper Content: Typically a minimum of 99.9% copper (Cu) for high-purity alloys, such as C12200.

- Phosphorus Content: Generally ranges from 0.015% to 0.040% to improve machinability and corrosion resistance.

- Tensile Strength: Ranges from approximately 200 MPa (soft annealed) to over 310 MPa (hard drawn).

- Elongation: Typically exceeds 40%, indicating good ductility.

- Grain Size: Varies by temper; for example, fine grain sizes can be around 0.040 mm or less.

- Available in various forms including straight lengths and coils.

- Common diameters range from 1/4 inch to 12 inches, with wall thicknesses tailored to specific applications.

What Is Copper Alloy Tube?

Copper alloy tubes are metallic tubes primarily composed of copper and one or more additional elements, such as zinc, tin, nickel, aluminum, or silicon. These alloys are engineered to enhance the properties of pure copper, making them suitable for various industrial applications. Here’s an overview of the key aspects of copper alloy tubes:

Composition and Types

- Alloying Elements: Commonly used elements in copper alloys include:

- Zinc (for brass)

- Tin (for bronze)

- Nickel (for cupronickel)

- Aluminum (for aluminum bronzes)

- Types of Copper Alloys: Some well-known types include:

- Brass: Copper and zinc.

- Bronze: Copper and tin.

- Cupronickel: Copper and nickel, known for its corrosion resistance, especially in marine environments.

Properties Of Copper Alloy Tubes

Corrosion Resistance: Copper alloys exhibit high resistance to corrosion, making them ideal for applications exposed to moisture or corrosive environments. For instance, alloys like cupronickel are particularly effective in seawater applications due to their ability to form a protective oxide layer.

Malleability and Ductility: These alloys maintain good malleability and ductility, allowing them to be easily formed into various shapes without breaking. This property is crucial for applications requiring bending or shaping of the tubes.

Thermal and Electrical Conductivity: Copper alloys retain excellent thermal and electrical conductivity, making them suitable for electrical wiring and heat exchangers.

Applications Of Copper Alloy Tubes

1. Plumbing Systems: Copper alloy tubes are widely used in plumbing for water supply lines due to their excellent corrosion resistance and durability. They are compliant with health standards for drinking water.

2. HVAC Systems: Used extensively in heating, ventilation, and air conditioning systems for refrigerant lines. Their ability to withstand high pressures and temperatures makes them ideal for these applications.

3. Refrigeration: Copper alloy tubes are integral in refrigeration systems, where they facilitate efficient heat exchange and fluid transport.

4. Marine Applications: Alloys like cupronickel are specifically utilized in marine environments due to their superior resistance to seawater corrosion, making them suitable for piping systems on ships and offshore platforms.

5. Electrical Applications: Due to their high electrical conductivity, copper alloy tubes are also used in electrical wiring and components.

6. Industrial Equipment: They are employed in various industrial applications, including heat exchangers, condensers, and other equipment requiring reliable thermal performance.

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

Mass Production Photos

Check how we will produce your finned tube bulk orders of in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

Copper Alloy Tubes Materials

What types of copper alloys do you offer for tubing?

We provide a range of copper alloys, including C11000 (pure copper), C28000 (brass), and C70600 (cupro-nickel), suitable for various applications.

Can you supply copper alloy tubes in specific dimensions?

What is the maximum length you can produce for copper alloy tubes?

We can produce copper alloy tubes up to 12 meters in length, depending on the alloy and specific manufacturing processes.

What is the typical lead time for copper alloy tube orders?

Our standard lead time is 4-6 weeks, depending on order size and specifications. We can expedite production if necessary.

What types of surface finishes are available for your copper alloy tubes?

We offer various surface finishes, including mill finish, polished, and coated options, to suit different applications and aesthetic preferences.

Can you provide samples of your copper alloy tubes before bulk ordering?

Yes, we can provide samples upon request to ensure our products meet your specifications before you place a bulk order.

Are your copper alloy tubes suitable for high-temperature applications?

Yes, our copper alloy tubes are designed to withstand high temperatures, making them ideal for HVAC and heat exchanger applications.

How do you ensure the quality of your copper alloy tubes?

We have rigorous quality control processes in place, including material testing, dimensional checks, and adherence to industry standards throughout production.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!