Evaporator Tube

Leading Evaporator Tubes Manufacturer

China Evaporator Tubes Manufacturer

As a leading China Evaporator Tubes Manufacturer, we specialize in high-performance copper and stainless steel tubes for HVAC evaporator, refrigeration, and industrial applications. With over 40 years of expertise, we ensure superior quality, competitive pricing, and reliable global delivery. Trust us for efficient, durable, and cost-effective evaporator tube solutions.

Technical Specification:

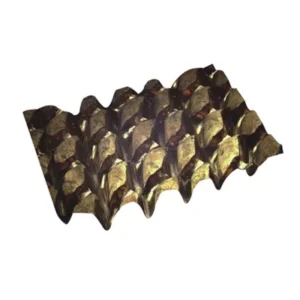

- Unique Fin Design: The outer fin features a specially designed channel that connects each fin to one another.

- Enhanced Vaporization: In full liquid evaporators, this structure forms stable vaporization cores and promotes frequent liquid vaporization into the channel.

- Improved Boiling Effect: The design helps the refrigerant boil effectively by allowing bubbles to continuously overflow, strengthening the boiling process.

- Superior Heat Transfer: The tube’s heat transfer coefficient is up to 7 times higher than that of plain tubes.

- Strengthened Inner Wall: The inner wall is enhanced to reduce thermal resistance, maximizing heat exchange on both sides of the copper tube.

Main Application:

The tube is suitable for:

- Central air conditioning centrifuge systems.

- Screw machines.

- Full liquid evaporators of chillers.

- Shell and tube heat exchangers for small temperature difference conditions.

Evaporator Tube Parameter

| Code | Standard Size | Standard Size | Plain End | Plain End | Finned Section | Finned Section | Finned Section | Finned Section |

|---|---|---|---|---|---|---|---|---|

| CTHE | Outside Diameter(mm) | Nominal Wall(mm) | Outside Diameter(mm) | Nominal Wall(mm) | Outside Diameter(mm) | Fin Height (mm) | Min Wall Under Fins(mm) | Fin Per Inch(mm) |

| A-4 | 19.05 | 0.635 | 19.05 | 1.05 | 18.9 | 0.6 | 0.56 | 50 |

| A-4B | 25.4 | 0.635 | 25.32 | 1.05 | 25.15 | 0.6 | 0.56 | 50 |

| A-4+ | 19.05 | 0.635 | 19.05 | 1.05 | 18.85 | 0.55 | 0.56 | 50 |

| A-4B+ | 25.4 | 0.635 | 25.32 | 1.05 | 25.15 | 0.55 | 0.56 | 50 |

| A-6 | 19.05 | 0.635 | 19.05 | 1.07 | 18.9 | 0.55 | 0.56 | 54 |

| A-6B | 25.4 | 0.635 | 25.32 | 1.07 | 25.15 | 0.55 | 0.56 | 54 |

| EX-1 | 19.05 | 0.635 | 19.05 | 1.13 | 18.9 | 0.55 | 0.56 | 48 |

| EX-1B | 25.4 | 0.635 | 25.32 | 1.13 | 25.15 | 0.55 | 0.56 | 48 |

| HET-1 | 19.05 | 0.635 | 19.05 | 1.09 | 19 | 0.5 | 0.56 | 54 |

| HET-2 | 19.05 | 0.635 | 19.05 | 1.09 | 19 | 0.5 | 0.585 | 54 |

What Is Evaporator Tube?

An Evaporator Tube is a critical component of an evaporator, which is part of a heat exchange system used to absorb heat from a fluid and facilitate its evaporation. The evaporator tube allows for the efficient transfer of heat between the fluid (such as refrigerant or water) and the surrounding environment. Evaporator tubes are commonly used in systems such as refrigeration, air conditioning, and industrial cooling processes.

Types of Evaporator Tubes

- Finned Tube Evaporators: These have fins attached to increase surface area for better heat exchange.

- Bare Tube Evaporators: Simple designs without fins, commonly used in applications where space is limited.

- Shell and Tube Evaporators: Comprising a bundle of tubes inside a shell, allowing for efficient heat transfer between two fluids

Functionality of Evaporator Tubes

Heat Absorption: Evaporator tubes are designed to absorb heat from the surrounding environment. They contain a refrigerant that evaporates as it absorbs heat, transitioning from a liquid to a gaseous state. This process cools the air or fluid passing over or through the tubes.

Refrigerant Flow: The refrigerant enters the evaporator as a low-pressure, low-temperature liquid after passing through an expansion device. As it flows through the evaporator tubes, it absorbs heat from the warmer air or fluid around it.

Phase Change: As the refrigerant absorbs heat, it boils and changes into a vapor. This phase change is critical because it allows the refrigerant to carry away heat from the space being cooled.

Heat Transfer Mechanisms: The heat transfer occurs primarily through conduction (heat moving through the tube walls) and convection (movement of warm air over the tube surfaces). Fins may be added to the tubes to increase surface area, enhancing heat transfer efficiency.

Cooling Effect: The cooled air or fluid is then circulated back into the environment, effectively lowering the temperature of the space being conditioned. The vaporized refrigerant exits the evaporator and is directed to the compressor, where it will be pressurized and sent to the condenser for further processing.

How Do Evaporator Tubes Work?

Refrigerant Entry: A low-pressure, low-temperature liquid refrigerant enters the evaporator tubes.

Heat Absorption: As the refrigerant flows through the evaporator tubes, it absorbs heat from the surrounding environment (e.g., air or liquid being cooled). This heat absorption occurs because the refrigerant is cooler than the medium it is cooling.

Evaporation: As heat is absorbed, the refrigerant inside the tubes begins to evaporate, changing from a liquid to a vapor state. This phase change (from liquid to gas) occurs at a low temperature, which enhances the cooling effect.

Coolant Output: The refrigerant, now in vapor form, exits the evaporator tubes and continues through the system, typically moving to the compressor for the next stage of the cooling cycle.

Cooling Medium: The air or fluid surrounding the evaporator tubes is cooled as its heat is transferred to the refrigerant inside the tubes. The now-cooled medium is circulated into the desired space (for air conditioning) or used for further processes (in refrigeration).

Applications Of Evaporator Tubes

- Power Generation: Used in power plants to condense steam from turbines, maximizing efficiency in the steam cycle.

- Refrigeration Systems: Integral to chillers and air conditioning units, where they condense refrigerants from gas to liquid.

- Chemical Processing: Employed in chemical reactors and distillation columns to manage heat during various processes.

- Marine Applications: Utilized in shipboard systems for cooling engine fluids and managing exhaust gases.

- Food Processing: Used in evaporators and chillers for temperature control during food preservation processes.

- Waste Heat Recovery: Facilitate the recovery of heat from industrial processes, converting it back into usable energy.

- HVAC Systems: Essential for releasing heat absorbed from indoor environments to the outside, maintaining comfortable indoor temperatures.

- Natural Gas Processing: Help in cooling and liquefying natural gas for storage and transport.

- Pipeline Transportation: Used to manage temperatures of fluids transported through pipelines, reducing energy losses.

- Pharmaceutical Manufacturing: Critical in maintaining temperature control during chemical reactions and distillation processes.

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

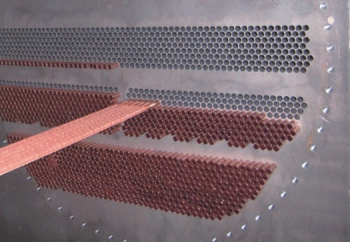

Mass Production Photos

Check how we will produce your finned tube bulk orders of in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Evaporator Heat Exchanger Tubes

Do you offer custom sizes for evaporator tubes?

Yes, we provide custom sizing options for our evaporator tubes based on your specific requirements. Please share the required dimensions, wall thickness, and length, and we will tailor the production accordingly.

What are the anti-corrosion properties of your evaporator tubes?

What materials are available for evaporator tubes besides copper?

Besides copper, we offer evaporator tubes made from cupronickel, stainless steel, and titanium, which are ideal for specific applications requiring extra corrosion resistance or strength.

Do you provide finned evaporator tubes for enhanced heat transfer?

Can you supply evaporator tubes that comply with ASTM standards?

Yes, all our evaporator tubes are manufactured in compliance with international standards, including ASTM B75 for copper tubes. We can provide full documentation upon request.

What is your minimum order quantity (MOQ) for evaporator tubes?

Our minimum order quantity for evaporator tubes typically starts at 500 meters, but we are flexible depending on specific project requirements and can accommodate smaller orders upon request.

Can your evaporator tubes be used in chemical processing environments?

Yes, our copper evaporator tubes are highly suitable for chemical processing due to their excellent corrosion resistance and durability, making them ideal for harsh environments.

Can your evaporator tubes be used in marine environments?

Yes, we offer evaporator tubes made from materials like cupronickel and titanium, which are highly resistant to corrosion from seawater, making them ideal for marine applications.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!