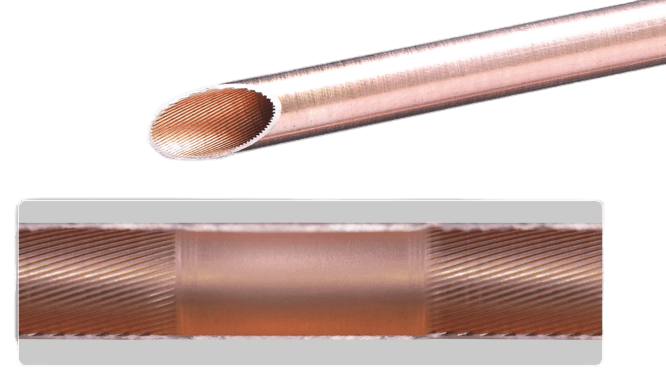

Inner Grooved Tube

China Inner Grooved Tube Supplier

China Inner Grooved Tube Supplier

As a China Inner Grooved Tube Supplier, our high-quality tubes are designed for superior heat transfer efficiency. Used extensively in HVAC, refrigeration, and industrial applications, they are produced with advanced techniques and strict quality control, ensuring they meet international standards while offering competitive pricing.

Technical Specification:

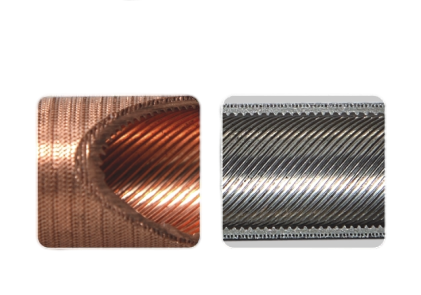

- Groove Design: The tube surface has continuous or intermittent spiral grooves, increasing the contact area and altering the refrigerant’s flow.

- Enhanced Heat Transfer: The heat transfer coefficient inside the tube is 1.5-2 times greater than that of a plain tube of the same specification.

- Refrigerant Flow: The refrigerant inside the tube cools water outside by its flow, improving the tube’s heat transfer capacity.

- Expanded Usage: The outer surface can be processed with corrugated spiral grooves for wider applications.

- Customizable Features: The tube can also have radial parallel grooves (spiral angle of zero) for radiator use, with customizable smooth sections at both ends and a maximum length of 7 meters.

Main Application:

- Commercial air conditioning heat exchangers

- Central air conditioning dry evaporators

- Electronic products

- Hot conduit radiators for solar energy devices

Copper Finned Tube Parameter

| Code | Outside Diameter(mm) | Nominal Wall(mm) | Bottom Wall Thickness(mm) | Number of Ridges | Helex Angle Degrees | Ridge Height (mm) |

|---|---|---|---|---|---|---|

| 9.52-0.5 | 9.52 | 0.5 | 0.4 | 60 | 18 | 0.2 |

| 9.52-0.6 | 9.52 | 0.6 | 0.47 | 60 | 18 | 0.2 |

| 9.52-0.7 | 9.52 | 0.7 | 0.6 | 60 | 18 | 0.2 |

| 12.7-0.6 | 12.7 | 0.6 | 0.45 | 60 | 18 | 0.25 |

| 12.7-0.7 | 12.7 | 0.7 | 0.53 | 60 | 18 | 0.25 |

| 12.7-0.8 | 12.7 | 0.8 | 0.65 | 60 | 18 | 0.25 |

| 15.88-0.7 | 15.88 | 0.7 | 0.5 | 75 | 23 | 0.3 |

| 15.88-0.8 | 15.88 | 0.8 | 0.635 | 75 | 23 | 0.25 |

| 15.88-0.9 | 15.88 | 0.9 | 0.711 | 75 | 23 | 0.25 |

What Is Inner Grooved Tube?

Key Features of Inner Grooved Tubes

Increased Surface Area: The grooves increase the surface area available for heat exchange, allowing for more efficient transfer of heat between fluids.

Enhanced Heat Transfer: By promoting turbulence in the fluid flowing through the tube, inner grooved tubes can significantly improve the heat transfer coefficient compared to smooth bore tubes. This results in better thermal performance.

Material Options: Inner grooved tubes can be made from different materials, with copper and aluminum being the most common. Copper offers superior thermal conductivity and corrosion resistance, while aluminum is lighter and often more cost-effective.

Advantages of Inner Grooved Tubes

Space Efficiency: Their design allows for smaller and lighter heat exchangers, which can be beneficial in applications where space is limited.

Cost-Effectiveness: By improving heat transfer efficiency, these tubes can reduce energy costs and improve overall system performance.

Versatility: Inner grooved tubes can be tailored for specific applications by varying groove depth, shape, and spacing to meet different thermal and fluid flow requirements.

Applications of Inner Grooved Tubes

Air Conditioning Systems:

Widely used in evaporators and condensers, inner grooved tubes enhance the efficiency of heat exchangers in HVAC systems.

Refrigeration Units:

They are essential in refrigeration systems, where effective heat exchange is critical for maintaining desired temperatures.

Heat Exchangers:

Inner grooved tubes are used in various types of heat exchangers to improve performance and reduce energy consumption.

Marine Applications:

Employed in shipboard cooling systems to enhance the efficiency of heat transfer processes.

Industrial Processes:

Used in chemical processing and manufacturing environments where efficient heat management is essential.

Book A Video Call

Your reliable China partner of finned tubes for heat exchangers

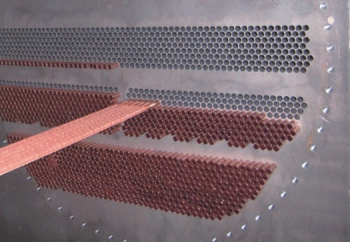

Mass Production Photos

Check how we will produce your finned tube bulk orders of in our future cooperation. We take every step seriously, from raw material to packaging, to ensure that the fin tubs delivered to your warehouse are 100% qualified.

Frequently Asked Questions

About Inner Grooved Tubes

Can you manufacture custom-sized inner grooved tubes for specific heat exchanger designs?

Yes, we specialize in customizing inner grooved tubes to fit your specific heat exchanger designs. Our production capabilities allow us to adjust tube diameter, wall thickness, groove patterns, and materials to match your requirements.

What is the expected lifespan of your inner grooved tubes in industrial HVAC systems?

Are your inner grooved tubes compliant with international quality standards?

Yes, all our inner grooved tubes meet international standards such as ASTM, EN, and DIN. We also perform stringent quality control tests, including dimensional inspections, pressure testing, and material certifications, to ensure consistent quality.

Do you offer any coating or corrosion protection for the inner grooved tubes used in marine environments?

Can you provide samples of inner grooved tubes for testing before placing a bulk order?

Yes, we can provide samples for testing purposes. Please specify the material, dimensions, and application of the inner grooved tubes, and we will arrange the necessary samples. Sample costs can be deducted from bulk orders.

What payment terms do you offer for international buyers?

For international orders, we typically offer payment terms such as 30% deposit upfront and 70% before shipment. Other payment options, including letters of credit (L/C) or payment via secure platforms, are available based on customer requirements.

Can your inner grooved tubes be used in high-pressure refrigerant systems?

Yes, our inner grooved tubes are designed to withstand high-pressure environments, commonly used in HVAC systems, heat exchangers, and refrigeration applications. The precise pressure ratings depend on the material and tube thickness, which we can customize according to your system requirements.

Could you provide detailed specifications for your inner grooved tubes, including material type and groove dimensions?

Our inner grooved tubes are available in various materials such as copper, copper-nickel, and aluminum. Groove dimensions can be customized based on client requirements, and tube lengths can be customized up to 10 meters.

Request A Free Quote

We'd like to work with you

Send us a message if you have any question or request a quote. Our expert will response within 24 hours and help you custom your finned tubes heat exchanger solution!