In the realm of modern HVAC systems, custom finned tubes stand as critical components, engineered to address the unique demands of diverse environments—from high-capacity commercial spaces to specialized institutional settings. These solutions, tailored to specific heat exchange requirements, balance efficiency, durability, and design flexibility, making them indispensable for challenging projects. This guide explores key considerations in selecting, designing, and implementing custom finned tube systems.

How to Select the Optimal Fin Material for Your Heat Exchange Requirements

The performance of a finned tube system hinges largely on fin material selection, which must align with core heat exchange objectives: thermal conductivity, corrosion resistance, weight, and cost.

• Thermal Conductivity: Materials with high thermal conductivity (e.g., aluminum) excel in applications requiring rapid heat transfer, such as cooling systems in data centers or industrial facilities.

• Corrosion Resistance: In environments with moisture, chemicals, or pollutants, materials like coated steel or copper alloys offer enhanced longevity, preventing degradation that could compromise efficiency.

• Weight Constraints: For applications with structural limitations—such as retrofitted systems or lightweight architectural designs—aluminum’s low density provides an advantage over heavier steel.

• Cost Efficiency: While copper offers superior conductivity, it may be cost-prohibitive for large-scale projects, making aluminum or galvanized steel more practical alternatives.

The optimal material balances these factors, ensuring the system meets both short-term performance and long-term durability needs.

Steel vs. Aluminum Fins: A Performance Comparison for Commercial Heating Applications

In commercial heating, steel and aluminum fins represent the most common choices, each with distinct strengths:

• Steel Fins: Known for their robustness, steel fins (often galvanized or stainless) thrive in high-temperature environments, such as boiler systems or industrial ovens. Their resistance to mechanical stress makes them ideal for settings with vibration or physical impact. However, their lower thermal conductivity compared to aluminum means they may require larger surface areas to achieve equivalent heat transfer.

• Aluminum Fins: Aluminum’s high thermal conductivity and lightweight properties make it a top choice for space-efficient heating systems, such as those in offices, malls, or hospitals. Its malleability allows for intricate designs (e.g., tightly spaced fins) that maximize surface area without adding excessive weight. While less resistant to extreme heat than steel, aluminum performs reliably in most commercial temperature ranges (typically -20°C to 150°C).

For high-temperature, heavy-duty applications, steel remains the preferred option; for efficiency and versatility in standard commercial settings, aluminum often delivers superior results.

Architectural Integration: Designing HVAC Systems with Aesthetically Pleasing Finned Tube Enclosures

As HVAC systems increasingly become visible elements of interior or exterior design, integrating finned tubes with architectural aesthetics has grown in importance. Custom enclosures and finishes allow these functional components to complement, rather than detract from, a space’s design language.

Manufacturers now offer options such as powder-coated fins in custom colors, sleek profiles, or decorative patterns that align with modern, minimalist, or industrial design themes. For exposed installations—such as in lobbies or outdoor seating areas—fins can be shaped to create visual interest, while still maintaining heat exchange efficiency.

Key to this integration is collaboration between HVAC engineers and architects: ensuring the fins’ spacing, color, and form enhance the space without sacrificing airflow or thermal performance.

Specialized Finned Tube Solutions for High-Security and Institutional Environments

High-security and institutional settings (e.g., research facilities, correctional centers, or healthcare complexes) demand finned tube systems that prioritize reliability, hygiene, and tamper resistance.

• Tamper Resistance: Fins in high-security areas are often designed with welded or reinforced connections to prevent unauthorized access or damage, ensuring uninterrupted operation.

• Hygiene Compliance: In healthcare settings, smooth, non-porous fin surfaces (e.g., polished stainless steel) minimize bacterial growth, adhering to strict sanitation standards. These fins are also easy to clean, reducing maintenance downtime.

• Redundancy: Systems in critical facilities may include redundant finned tube arrays, ensuring heat exchange continues even if one section fails—a critical feature for environments where temperature control is mission-critical.

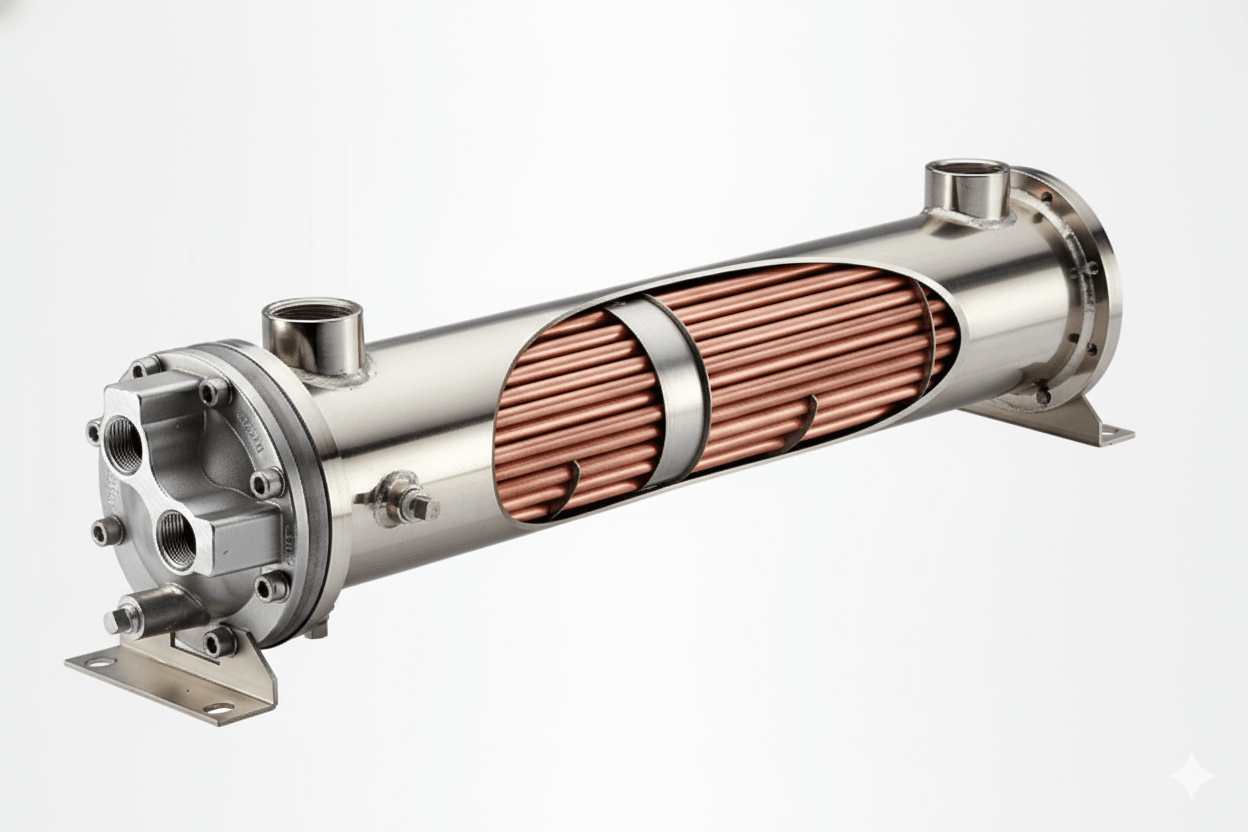

The Engineering Behind Permanently Bonded Fins: Maximizing Heat Transfer Efficiency

Permanent bonding between fins and tubes eliminates air gaps that hinder heat transfer, a key factor in maximizing efficiency. Common bonding methods include:

• Mechanical Bonding: Processes like expansion or crimping create a tight seal between fins and tubes, ideal for low-temperature applications.

• Chemical Bonding: Adhesives designed for high temperatures form durable bonds in systems with moderate heat demands.

• Metallurgical Bonding: Techniques such as brazing or welding fuse fins and tubes at the molecular level, creating the most efficient thermal connection. This method is preferred for high-temperature systems, as it withstands extreme heat without degradation.

The choice of bonding method depends on operating temperatures, material compatibility, and desired lifespan, with metallurgical bonding offering the highest long-term efficiency.

Customization Capabilities in Modern Finned Tube Manufacturing: Beyond Standard Catalog Options

Advancements in manufacturing—such as CNC machining, laser cutting, and 3D modeling—enable customization beyond standard sizes and shapes. Manufacturers now offer:

• Custom Fin Profiles: Fins can be shaped (e.g., triangular, wavy) to optimize airflow or fit unique spaces.

• Variable Fin Spacing: Tighter spacing increases surface area for high-efficiency applications, while wider spacing reduces clogging in dusty environments.

• Mixed-Material Systems: Hybrid designs (e.g., aluminum fins with copper tubes) combine materials to balance conductivity and cost.

These capabilities allow engineers to address project-specific challenges, from limited installation space to unusual heat loads.

Material Selection Guide for Finned Tubes in Corrosive or Demanding Environments

Corrosive environments—such as those with high humidity, salt, or chemical exposure—require specialized materials to prevent degradation:

• Stainless Steel: Offers excellent resistance to rust and chemical corrosion, making it suitable for coastal or industrial settings.

• Copper-Nickel Alloys: Resist corrosion in saltwater or acidic environments, ideal for marine or chemical processing facilities.

• Coated Fins: Epoxy or polyurethane coatings add a protective layer to steel or aluminum fins, extending their lifespan in humid or polluted areas.

In demanding environments, material selection is critical to avoiding premature failure and maintaining system efficiency.

Space-Saving Finned Tube Designs for Projects with Limited Installation Area

In projects where space is constrained—such as urban high-rises or retrofitted buildings—compact finned tube designs maximize efficiency without sacrificing performance:

• Microchannel Fins: Small-diameter tubes with dense fin arrays reduce overall size while maintaining high heat transfer rates.

• Vertical Orientation: Fins mounted vertically save floor space, making them suitable for narrow corridors or wall-mounted systems.

• Custom Bends and Shapes: Fins can be bent or curved to fit around obstacles, utilizing otherwise unused space.

These designs prove that limited space need not compromise heating or cooling efficiency, offering practical solutions for urban or constrained environments.

Conclusion

Custom finned tube solutions are essential for addressing the diverse challenges of modern HVAC projects. By carefully selecting materials, leveraging advanced manufacturing, and prioritizing both performance and design, engineers and architects can create systems that meet the unique demands of any environment—from high-security facilities to aesthetically driven commercial spaces. As technology advances, the customization capabilities of finned tubes will continue to expand, offering even more innovative solutions for the most challenging HVAC projects.