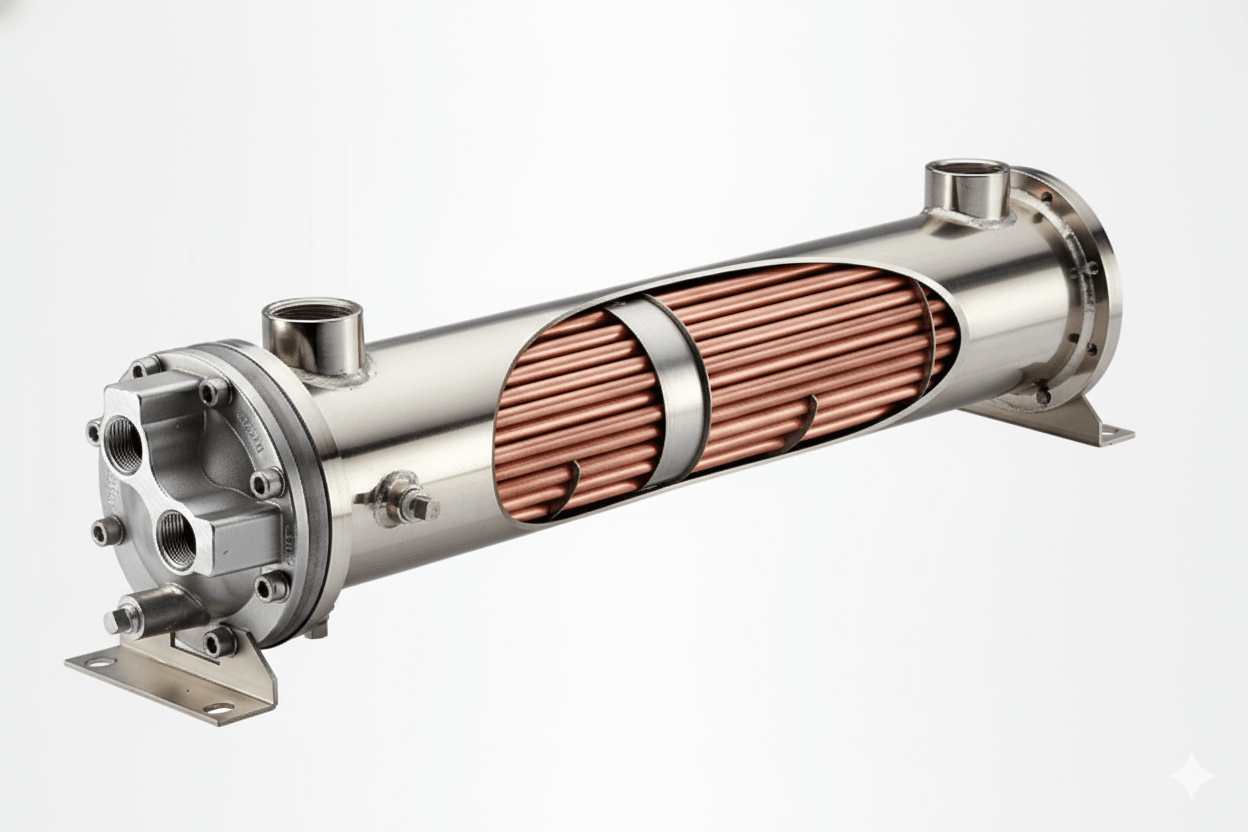

Finned tube heat exchangers are the unsung heroes of many HVAC systems, quietly working behind the scenes to ensure comfortable indoor environments and efficient energy use. These crucial components facilitate the transfer of heat between fluids, playing a pivotal role in heating, cooling, and ventilation processes. Choosing the right finned tube heat exchanger isn’t just about fitting a part into a system; it’s about optimizing performance, ensuring longevity, and maximizing energy savings. This guide will walk you through the essential considerations for making an informed decision.

How Custom Finned Tube Design Impacts Energy Efficiency in Commercial HVAC Applications

In commercial HVAC systems, energy efficiency is paramount. A significant portion of operating costs in large buildings is tied to heating and cooling. This is where custom finned tube design truly shines. While off-the-shelf heat exchangers may suffice for some applications, a custom-designed unit can be precisely engineered to meet the unique demands of a specific commercial space.

Tailored designs can optimize fin density, tube spacing, and overall coil dimensions to achieve the ideal balance between heat transfer efficiency and airflow resistance. For instance, in an application where airflow is restricted, a design with fewer, wider fins might be more effective. Conversely, in a space with ample airflow, a higher fin density could maximize heat transfer. These seemingly minor adjustments, when precisely calculated, can lead to substantial energy savings and improved system performance over time. It’s about getting the most thermal exchange for the least amount of energy input.

Comparing Copper vs. Aluminum Finned Tubes: Which Material Delivers Superior HVAC Performance?

The choice of material for finned tubes is a fundamental decision impacting both performance and cost. Copper and aluminum are the two most common options, each with distinct advantages.

Copper boasts superior thermal conductivity, meaning it transfers heat more efficiently. It’s also highly durable and resistant to many forms of corrosion, making it a reliable choice for long-term performance. However, copper is generally more expensive.

Aluminum, while having slightly lower thermal conductivity than copper, offers a significant cost advantage. It’s also lighter, which can be beneficial for installation and structural considerations. Modern aluminum alloys and manufacturing techniques have improved its corrosion resistance, making it a viable option for many HVAC applications.

The “superior” material depends heavily on the specific application’s requirements, budget constraints, and environmental factors. For high-performance, long-lifespan systems where initial cost is less critical, copper might be preferred. For cost-sensitive projects or where weight is a factor, aluminum can offer excellent value.

Extending the Lifespan of Finned Tube Heat Exchangers: Essential Maintenance Practices

Even the most robust finned tube heat exchanger requires proper care to ensure its longevity and maintain optimal performance. Essential maintenance practices can significantly extend the lifespan of these critical components.

Regular cleaning is crucial. Fins can accumulate dust, dirt, and debris, which acts as an insulator, reducing heat transfer efficiency and increasing energy consumption. Depending on the environment, this might involve vacuuming, brushing, or even chemical cleaning. It’s also important to inspect for any physical damage to the fins, such as bending or crushing, which can impede airflow. Checking for refrigerant or fluid leaks and ensuring proper system pressure are also vital steps. Proactive maintenance not only prevents costly breakdowns but also ensures the system operates at peak efficiency throughout its service life.

Energy Savings Calculation: The ROI of Upgrading to High-Efficiency Finned Tube Heat Exchangers

Upgrading to high-efficiency finned tube heat exchangers can represent a significant investment, but the return on investment (ROI), primarily through energy savings, can be compelling. Calculating this ROI involves a few key steps.

First, determine the energy consumption of the existing system. This can be done by monitoring utility bills and system run times. Next, estimate the energy savings achievable with the new, more efficient heat exchanger, often provided by the manufacturer based on its efficiency ratings. The difference in energy consumption, multiplied by the cost of energy, provides the annual savings. Comparing these annual savings to the initial investment cost (including purchase and installation) reveals the payback period. Many organizations find that the energy savings quickly offset the upgrade cost, making it a financially sound decision.

Industrial HVAC Solutions: Specialized Finned Tube Designs for Harsh Operating Environments

Industrial HVAC applications often present harsh operating environments that demand specialized finned tube designs. Unlike commercial or residential settings, industrial facilities might encounter corrosive atmospheres, extreme temperatures, high humidity, or airborne particulates.

In such conditions, standard materials and designs may quickly degrade. Specialized solutions include using more robust materials like stainless steel or exotic alloys for tubes and fins, applying advanced protective coatings (such as epoxy or phenolic coatings) to resist corrosion, and designing wider fin spacing to prevent clogging from dust or fibers. Furthermore, the construction might be reinforced to withstand vibration or higher pressures. These tailored designs ensure the heat exchanger can reliably perform under challenging circumstances, minimizing downtime and maintenance costs in industrial settings.

The Science Behind Heat Transfer Enhancement: Modern Fin Designs and Their Impact

The efficiency of a finned tube heat exchanger largely hinges on its ability to maximize heat transfer. The science behind heat transfer enhancement is continuously evolving, leading to modern fin designs that significantly impact performance.

Traditional flat fins are being supplemented or replaced by designs like louvered fins, wavy fins, or corrugated fins. These geometries increase the surface area available for heat exchange and, more importantly, disrupt the boundary layer of airflow, promoting turbulent flow. Turbulent flow leads to better mixing of the air, which in turn enhances the rate of heat transfer. The precise shaping and spacing of these fins are determined through complex computational fluid dynamics (CFD) simulations and experimental validation, allowing engineers to fine-tune designs for optimal thermal performance in various applications.

Retrofit Guide: Upgrading Existing HVAC Systems with Advanced Finned Tube Technology

For organizations looking to improve the efficiency of their existing infrastructure without a complete system overhaul, retrofitting existing HVAC systems with advanced finned tube technology offers a cost-effective solution.

A successful retrofit begins with a thorough assessment of the current system’s performance and limitations. This includes evaluating the existing heat exchanger’s capacity, age, and condition. The next step involves selecting a new finned tube heat exchanger that can integrate seamlessly with the existing system’s connections and footprint while offering significantly improved efficiency. Installation might require some modifications to piping or ductwork, but these are typically less extensive than a full system replacement. A well-executed retrofit can dramatically enhance energy efficiency, reduce operating costs, and extend the usable life of the entire HVAC system.

Corrosion Prevention in HVAC Heat Exchangers: Protective Coatings and Material Innovations

Corrosion is a major enemy of HVAC heat exchangers, leading to reduced efficiency, leaks, and premature failure. Effective corrosion prevention is crucial for long-term system integrity.

Beyond material selection, protective coatings play a vital role. Coatings like epoxy, phenolic, or E-coatings create a barrier between the metal surface and corrosive elements present in the air or water. These coatings are applied through specialized processes to ensure uniform coverage and strong adhesion. Furthermore, material innovations continue to advance, with the development of corrosion-resistant alloys and hybrid materials that offer enhanced protection without compromising heat transfer capabilities. Implementing a robust corrosion prevention strategy is an investment that pays dividends in extended equipment life and consistent performance.

Case Studies: Energy Consumption Before and After Finned Tube Heat Exchanger Optimization

Real-world examples powerfully illustrate the benefits of optimizing finned tube heat exchangers. Case studies provide compelling evidence of energy consumption reduction before and after optimization.

For instance, a commercial office building might have reported a significant drop in cooling costs after replacing outdated, fouled coils with new, high-efficiency models featuring enhanced fin designs and protective coatings. Similarly, an industrial facility could document a substantial decrease in heating expenses after retrofitting its process heating system with specialized finned tubes designed for harsh conditions. These case studies often detail the specific challenges faced, the solutions implemented, and the measurable improvements in energy consumption, providing valuable benchmarks and demonstrating the tangible financial and operational advantages of intelligent heat exchanger selection and optimization.

HVAC System Sizing: How to Calculate the Correct Finned Tube Heat Exchanger Capacity

Proper HVAC system sizing is fundamental to achieving optimal performance and efficiency. A critical part of this is calculating the correct finned tube heat exchanger capacity. An undersized unit won’t meet the heating or cooling demand, leading to occupant discomfort and inefficient operation, while an oversized one can lead to short cycling, wasted energy, and increased wear and tear.

The calculation involves several key parameters: the desired heat transfer rate (BTU/hr or kW), the inlet and outlet temperatures of both the primary and secondary fluids, the flow rates of these fluids, and the properties of the fluids themselves. Engineers use specialized software and formulas, often incorporating factors like ambient conditions and system pressure drops, to determine the precise surface area and fin configuration required to achieve the target heat exchange. Accurate sizing ensures the heat exchanger operates within its most efficient range, contributing to overall system longevity and performance.