In the realm of industrial processes, the need for efficient heat transfer is a critical consideration. From manufacturing plants to power stations and HVAC systems, heat exchangers play a central role in keeping systems running smoothly. One essential component that drives efficiency in these applications is the finned tube. But what exactly are finned tubes, and why are they used in industrial applications?

In this blog, we will dive into the various uses of finned tubes in industrial sectors, the benefits they provide, and why they are preferred in specific applications over other heat transfer methods.

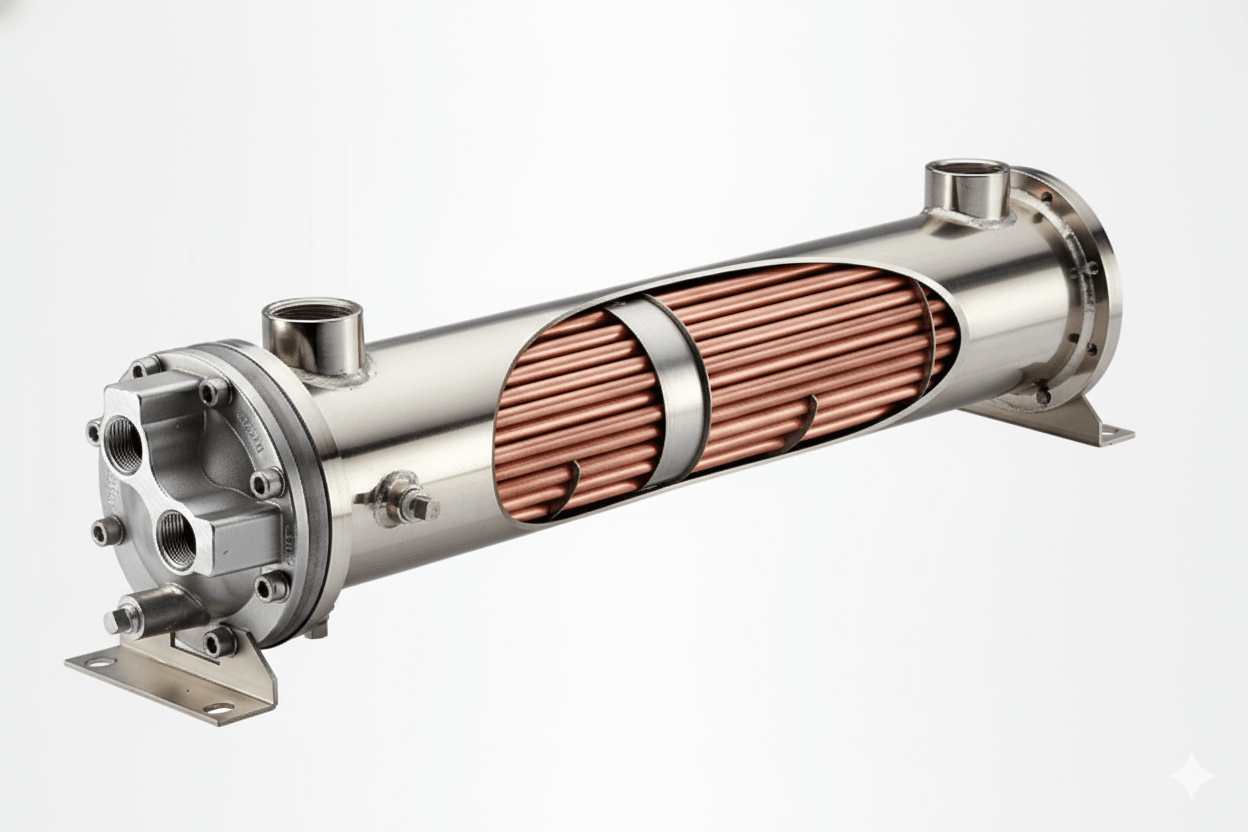

What Are Finned Tubes?

Finned tubes are heat exchangers that consist of a central tube (usually made from metal, such as copper or aluminum) surrounded by fins or “blades.” The fins increase the surface area of the tube, allowing for better heat transfer between fluids or gases. These tubes are commonly used in applications where efficient heat dissipation or absorption is required.

The principle behind their design is simple: by increasing the surface area, heat exchange becomes more efficient. The tube itself carries a hot or cold fluid, while the fins help dissipate or absorb heat from the surrounding environment. Finned tubes are found in a wide variety of industries, including HVAC, automotive, power generation, and refrigeration.

1. HVAC Systems

One of the most common industrial uses of finned tubes is in HVAC (Heating, Ventilation, and Air Conditioning) systems. In HVAC, efficient heat transfer is essential for maintaining climate control and energy efficiency.

- Evaporators and Condensers: In HVAC systems, finned tubes are used in both evaporators and condensers. The fins increase the surface area of the tubes, allowing heat to be absorbed from the air (in the case of the evaporator) or transferred to the air (in the case of the condenser). The improved heat exchange helps keep air temperatures consistent while minimizing energy consumption.

- Energy Efficiency: Finned tube heat exchangers are used to maximize the efficiency of these systems. By enhancing the heat transfer process, they enable HVAC systems to use less energy to achieve the desired cooling or heating, resulting in lower utility costs.

2. Power Generation Plants

In power generation, heat exchangers are a critical component in maintaining the efficiency of boilers, condensers, and cooling towers. Finned tubes are especially useful in these applications due to their ability to handle high temperatures and large volumes of heat.

- Boiler Heat Exchangers: Finned tubes are used extensively in boiler systems, particularly in applications involving steam. The high surface area provided by the fins allows for more efficient heat absorption, which improves the boiler’s overall performance. In boilers, finned tubes help transfer heat from the hot gases to the water, creating steam more efficiently.

- Cooling Systems: Power plants also require efficient cooling systems to prevent equipment from overheating. Finned tube heat exchangers are used in cooling towers and air-cooled condensers to transfer excess heat from hot fluids to the surrounding air. These systems are particularly important in preventing equipment failure in plants that operate in high-temperature environments.

3. Chemical and Petrochemical Industries

In chemical and petrochemical industries, managing heat exchange in reactors, distillation columns, and cooling systems is a critical concern. Finned tubes offer significant advantages in these applications.

- Reactors and Heat Recovery Systems: In many chemical plants, finned tubes are used in heat recovery systems and reactors to efficiently transfer heat from reaction vessels or exhaust gases to cooler fluids. The higher surface area of the finned tubes allows for faster heat dissipation, which helps maintain optimal operating temperatures in chemical reactions.

- Coolers and Heaters: Finned tubes are also used in cooling and heating applications in refineries and petrochemical plants. They are ideal for transferring heat in both directions, whether removing excess heat from a process or supplying heat for distillation or other chemical processes. Their high thermal conductivity and surface area make them well-suited for these harsh industrial environments.

4. Refrigeration Systems

Finned tubes are a key component in refrigeration systems, helping them achieve greater efficiency in both industrial and commercial applications.

- Air-Cooled Condensers: Finned tube heat exchangers are widely used in refrigeration systems, particularly in air-cooled condensers. These systems rely on the finned tubes to increase the surface area, allowing heat to be transferred from the refrigerant gas to the surrounding air more efficiently. This enhanced heat exchange helps maintain the desired cooling effect with lower energy consumption.

- Evaporators: In refrigeration applications, finned tubes are often used in evaporators, where they help increase the surface area for better heat absorption from the air. The ability of the finned tubes to effectively transfer heat from the environment to the refrigerant gas ensures that the refrigeration system can cool more effectively, even under demanding conditions.

5. Automotive and Aerospace Industries

The automotive and aerospace industries require efficient thermal management to ensure the proper functioning of engines, turbines, and other critical systems. Finned tubes are widely used in these sectors for their ability to dissipate heat efficiently.

- Radiators: In automotive applications, finned tubes are commonly used in radiators for both cooling the engine and managing heat. The fins increase the surface area for heat dissipation, allowing the radiator to cool the engine fluid more efficiently. This is crucial for keeping the engine within optimal operating temperatures and preventing overheating.

- Turbine Cooling: In aerospace applications, finned tubes can be used to cool turbine systems by transferring heat from the turbine blades to the surrounding air or coolant. Given the high temperatures that turbines operate under, finned tubes are ideal for maintaining the system’s performance and preventing heat-related failures.

6. Marine Applications

In the marine industry, finned tubes are used in various heat exchangers for cooling systems, including marine engines and desalination units.

- Marine Heat Exchangers: Finned tubes are used in heat exchangers to cool marine engines, which generate large amounts of heat during operation. The high surface area of the fins helps dissipate this heat into the surrounding seawater, ensuring that the engine does not overheat. Similarly, finned tubes are used in desalination systems to manage the heat produced during the desalting process.

Why Choose Finned Tubes for Industrial Applications?

Finned tubes are favored in industrial applications for several reasons:

- Increased Heat Transfer Efficiency: The added surface area provided by the fins significantly enhances heat transfer, which improves the overall efficiency of heat exchangers and cooling systems.

- Compact Design: Finned tube heat exchangers can provide high performance in compact spaces, making them ideal for industries where space is limited.

- Durability: Finned tubes, especially those made from materials like copper, aluminum, or stainless steel, offer excellent resistance to corrosion and wear, even in extreme operating conditions.

- Energy Savings: By improving heat transfer, finned tubes reduce energy consumption, helping industries lower operational costs and meet sustainability goals.

Conclusion: The Versatility of Finned Tubes in Industrial Applications

Finned tubes are indispensable in industrial applications that require efficient heat transfer. Their ability to increase surface area allows for faster, more effective heat exchange in systems like HVAC, power generation, chemical plants, refrigeration, automotive, and more. As industries continue to demand higher energy efficiency and more compact designs, the role of finned tubes will only continue to grow.

Whether used for cooling, heating, or heat recovery, finned tubes provide numerous benefits across various sectors. Their versatility, efficiency, and cost-effectiveness make them a critical component in the industrial heat exchange market. By understanding the specific needs of your industry and selecting the right finned tube design, you can optimize performance, reduce energy consumption, and improve the longevity of your systems.