High fin tubes are an essential part of heat exchanger systems used in various industries, from HVAC and refrigeration to power generation and marine applications. These specialized tubes help improve heat transfer by increasing the surface area available for heat dissipation. In this blog, we’ll dive into what high fin tubes are, how they work, and the industries that rely on them. By the end, you’ll have a clearer understanding of why they’re a go-to solution for improving energy efficiency and cooling performance.

What Are High Fin Tubes?

High fin tubes are tubes—usually made of copper or aluminum—that have fins attached along their length. These fins extend outward from the tube’s surface, creating more area for heat exchange. The greater the surface area, the more heat can be transferred between the fluid inside the tube and the surrounding air or another cooling medium.

The “high” in high fin tubes refers to the length of the fins. Longer fins provide more surface area, which leads to better heat dissipation. These tubes are commonly used in heat exchangers, where rapid heat transfer is required in limited space.

How Do High Fin Tubes Work?

The fundamental principle behind high fin tubes is to increase the surface area for heat exchange without making the tube itself larger. The fins on the tube provide more contact points with the air or another cooling fluid, making it easier for heat to move away from the system.

When hot fluids (like refrigerants or engine coolant) flow through the tube, the fins allow heat to be transferred efficiently to the surrounding environment. This makes high fin tubes ideal for applications where cooling or heating must happen quickly and effectively in compact spaces.

The Benefits of High Fin Tubes

- Improved Heat Transfer Efficiency

The main advantage of high fin tubes is their ability to enhance heat transfer. By increasing the surface area, they allow more heat to be transferred in a shorter period, which is crucial in systems like air-cooled heat exchangers or refrigeration units. - Space Efficiency

High fin tubes help you achieve better performance without requiring a larger physical footprint. For systems where space is limited, such as in automotive or HVAC applications, high fin tubes provide a way to get maximum heat transfer in a smaller, more compact design. - Cost-Effective Solution

Instead of redesigning entire systems for better cooling, high fin tubes offer a cost-effective alternative. They improve performance without the need for costly upgrades to the core equipment. This makes them an affordable option for industries looking to optimize their systems. - Corrosion Resistance

Copper and aluminum are materials commonly used for high fin tubes, and both are known for their resistance to corrosion. This makes high fin tubes an excellent choice for industries where systems are exposed to harsh environmental conditions, such as marine or industrial cooling systems. - Versatility

High fin tubes are incredibly versatile and can be used in a wide variety of systems. They can be customized in terms of tube material, fin height, and spacing to meet the specific needs of different applications.

Where Are High Fin Tubes Used?

High fin tubes are found in many industries, each benefiting from the improved heat transfer and space-saving design. Here are some key applications:

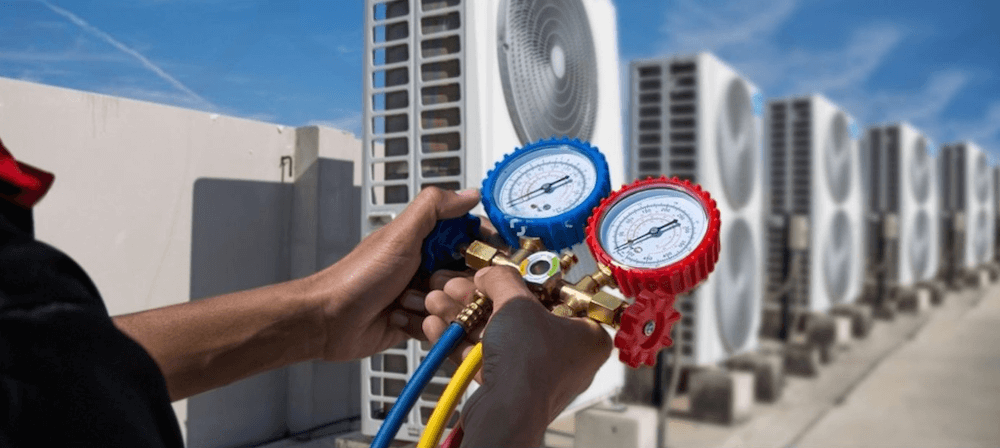

- HVAC Systems

In HVAC systems, high fin tubes are commonly used in air-cooled condensers and evaporators. These systems need to dissipate a lot of heat efficiently, and the increased surface area of high fin tubes ensures that heat is transferred effectively to the surrounding air. - Refrigeration

High fin tubes are also essential in refrigeration systems. They help cool refrigerants more efficiently, maintaining low temperatures in commercial refrigerators, industrial chillers, and cooling towers. - Power Generation

In power plants, high fin tubes are used in heat exchangers that cool fluids involved in thermal energy transfer. The ability to efficiently dissipate heat is crucial for maintaining optimal performance and preventing system overheating. - Marine Applications

Marine engines and cooling systems benefit from high fin tubes, especially since these systems are often exposed to corrosive saltwater environments. Copper and aluminum high fin tubes offer durability, preventing corrosion and ensuring long-lasting performance. - Automotive and Aerospace

In automotive radiators and aerospace cooling systems, high fin tubes help maintain engine temperatures and ensure reliable performance. Their compact design allows for effective heat dissipation in small, tight spaces.

Key Considerations When Choosing High Fin Tubes

While high fin tubes offer numerous benefits, there are a few things to keep in mind when selecting the right ones for your system:

- Material and Fin Design

Choosing the right material (copper, stainless steel, aluminum, etc.) is crucial for corrosion resistance and heat transfer performance. The design of the fins—such as their height, thickness, and spacing—also impacts the effectiveness of the heat exchange process. - Airflow Efficiency

For high fin tubes to work at their best, it’s important to ensure that there’s sufficient airflow around the fins. Poor airflow can reduce the efficiency of heat transfer, so proper ventilation is key to maximizing performance. - Environmental Conditions

High fin tubes need to be selected based on the environment in which they will be used. For example, systems exposed to saltwater or extreme temperatures may require specialized materials or coatings to prevent corrosion.

High fin tubes are a highly effective solution for improving heat transfer in compact spaces. With their increased surface area and ability to handle high heat dissipation, they are essential in industries such as HVAC, refrigeration, power generation, and marine applications. By choosing the right high fin tube for your system, you can boost efficiency, save space, and reduce costs—all while ensuring long-lasting performance.

Incorporating high fin tubes into your system design will not only optimize thermal performance but also contribute to overall energy efficiency. Whether you’re upgrading an existing system or designing a new one, high fin tubes are a smart, cost-effective choice for tackling heat transfer challenges.