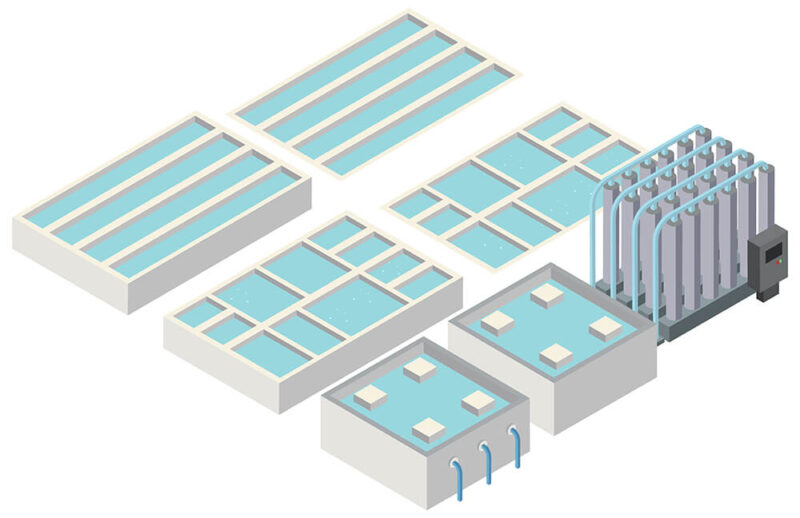

As a key component of the refrigeration system, cold storage evaporators play a central role in realizing a low-temperature storage environment. They are heat transfer devices installed inside the warehouse, and together with the compressor, condenser and throttling device constitute the four core components of the refrigeration system. Through the liquid refrigerant in the evaporator internal heat absorption and evaporation into a gaseous process, cold storage evaporator can effectively absorb the heat inside the warehouse, so as to realize the temperature reduction, to achieve the purpose of refrigeration.

First, the main types of cold storage evaporator

Cold storage evaporator is mainly divided into two categories: row tube evaporator and chiller evaporator. These two kinds of evaporator in the structure, working principle, applicable scene and maintenance requirements and so on each has its own characteristics.

1. Row tube evaporator row tube evaporator is usually fixed installed in the warehouse wall or top, the use of natural convection way to achieve the cooling air flow. Its distinctive features include: efficient heat transfer: the structural design of the tube evaporator ensures full contact between the refrigerant and the cooled medium, thus improving the overall heat transfer efficiency. Energy saving and power saving: Compared with chillers, row tube evaporators use a smaller amount of refrigerant, which helps to reduce energy consumption and realize energy saving. Uniform refrigeration: The even distribution of the row of tubes results in a more uniform temperature in the warehouse, which is particularly suitable for storing products that are sensitive to temperature fluctuations. However, there are some problems with the row tube evaporator, such as the accumulation of frost layer will affect the heat transfer efficiency, so it needs to be equipped with defrosting device; at the same time, the row tube occupies a larger space, which may cause some trouble to the stacking of goods and cleaning work.

Characteristics: Good thermal conductivity, especially aluminum row pipe, can improve the energy efficiency ratio and reduce energy consumption due to its high thermal conductivity. Operating in natural convection mode, it is advantageous for keeping the humidity of goods. Takes up less space and has a balanced distribution, which helps to save energy and electricity. Suitable for long-term storage of products that are prone to water loss, such as fresh fruits and vegetables.

2. Chiller-type evaporator chiller-type evaporator is mostly hung on the top or side of the warehouse, accelerating the cooling process through the forced ventilation of the fan. This type of evaporator is more common in high temperature cold storage, especially in Freon refrigeration system. Advantages include: rapid cooling: chillers are able to quickly reduce the temperature in the warehouse through the forced ventilation mechanism, which is ideal for items that need to be frozen quickly. Easy defrosting: chillers are usually equipped with a high degree of automation for defrosting, which reduces the need for manual intervention and improves efficiency. However, there are some shortcomings with chillers, such as higher power consumption during operation and the possibility of water loss and drying of unpackaged food. Therefore, the choice needs to be weighed against the specific application requirements.

Characteristics: fast cooling speed, suitable for occasions requiring rapid cooling. Can provide better temperature uniformity due to the presence of forced convection. Better control of humidity in the warehouse, but may lead to product moisture loss (air drying). Relatively easy to install and dismantle, especially suitable for tall cold storage space.

Second, the selection and application of cold storage evaporator

When selecting the cold storage evaporator, it is necessary to comprehensively consider the type of warehouse, the characteristics of the stored items, refrigeration needs and cost-effectiveness and other factors. For example: for the need for long time preservation of fresh fruits and vegetables and other commodities prone to water loss of the warehouse, row and tube evaporator may be a better choice, because it can provide a more uniform refrigeration effect, reduce the loss of water in the food phenomenon. For warehouses pursuing a rapid cooling effect, such as quick-frozen warehouses, chillers may be more suitable, as they can quickly reduce the temperature in the warehouse to meet the demand for rapid freezing. In addition, with the rise in transportation costs and installation costs, small and medium-sized cold storages tend to consider the cost-benefit ratio when choosing an evaporator. Chillers are favored for their small size, ease of installation and lower total cost of ownership.