Copper is a versatile material widely used in plumbing, HVAC systems, and heat exchangers. However, the terms copper pipe and copper tube often confuse buyers and professionals alike. While they may seem interchangeable, these two products serve different purposes and have distinct characteristics. Understanding the differences is crucial for selecting the right option for your application.

The primary difference between copper pipe and copper tube lies in their sizing standards, applications, and manufacturing processes. Copper pipes are typically used for plumbing, measured by internal diameter, and designed to handle fluid flow. Copper tubes, on the other hand, are measured by external diameter and are ideal for precision applications like HVAC systems and heat exchangers.

Understanding Copper Pipe

Copper pipes are widely used in residential and commercial plumbing systems due to their durability and corrosion resistance. Let’s explore their key attributes:

- Sizing and Measurement:

Copper pipes are measured by nominal internal diameter (ID) and wall thickness, often expressed in terms of “types” (Type K, L, M). These classifications indicate the pipe’s thickness:- Type K: Thickest walls, suitable for underground water lines.

- Type L: Medium thickness, used in standard plumbing.

- Type M: Thinner walls, often used for light-duty applications.

- Applications:

Copper pipes are most commonly used in:- Domestic water supply lines.

- Gas piping systems.

- Drainage systems (when corrosion resistance is required).

- Installation and Handling:

Copper pipes are rigid and require fittings like elbows or couplings for directional changes. They are soldered, brazed, or threaded to create leak-proof connections. - Pressure Handling:

Copper pipes are designed to handle significant water pressure, making them ideal for plumbing systems.

Understanding Copper Tube

Copper tubes, while similar in material, differ in their measurement and application. Their design focuses on precision and thermal efficiency.

- Sizing and Measurement:

Copper tubes are measured by their external diameter (OD) and are often classified by thickness standards such as American Wire Gauge (AWG) or a simple series like ACR (air conditioning and refrigeration). - Applications:

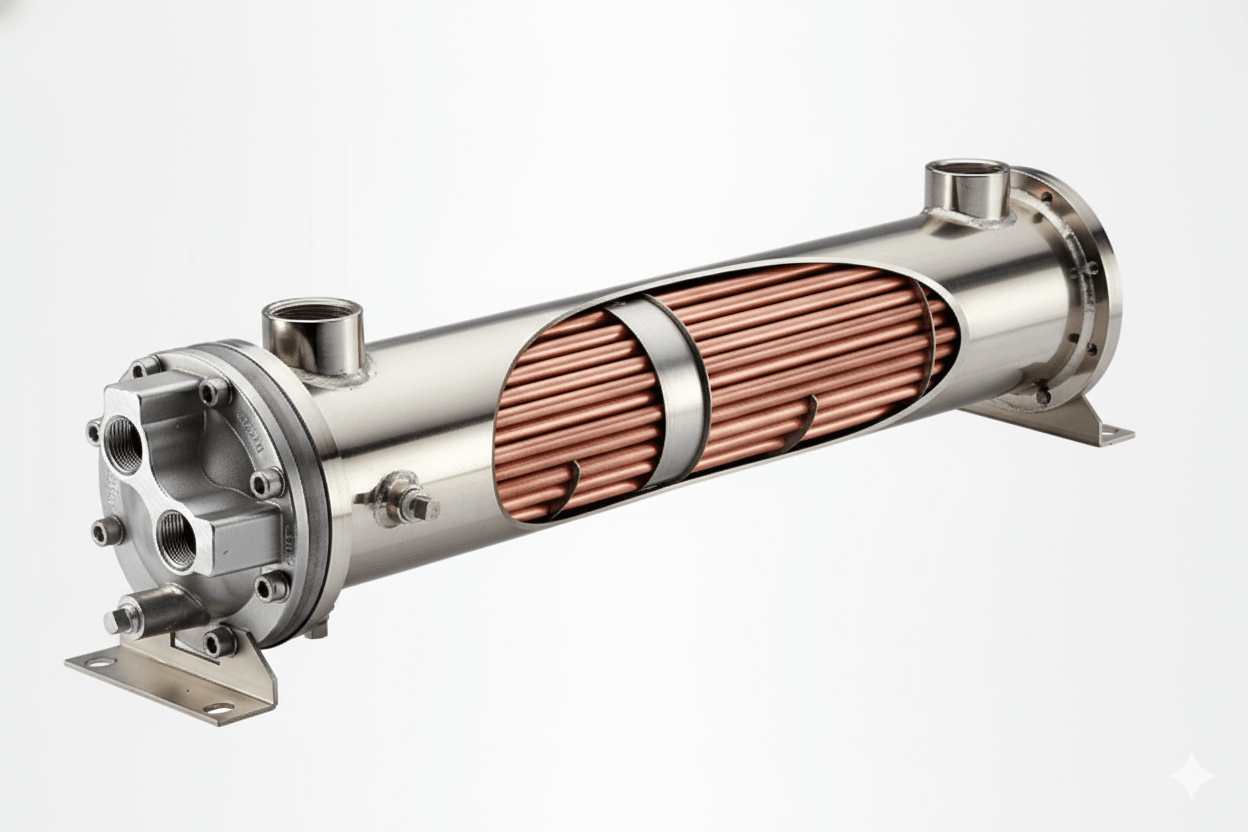

Copper tubes are predominantly used in:- HVAC systems for refrigerant lines.

- Heat exchangers and radiators.

- Medical gas lines in hospitals.

- Industrial systems requiring precise flow rates.

- Flexibility:

Unlike pipes, copper tubes can be either rigid or flexible. Flexible copper tubes are easier to install in tight spaces and are commonly used in air conditioning systems. - Thermal Conductivity:

Copper tubes are favored in heat transfer applications due to their excellent thermal conductivity.

Key Differences Between Copper Pipe and Copper Tube

- Measurement Standards:

- Pipe: Measured by internal diameter (ID) and wall thickness.

- Tube: Measured by external diameter (OD) for precision in fitting and flow control.

- Applications:

- Pipe: Ideal for fluid flow, such as water or gas delivery.

- Tube: Used for specialized applications, especially where precision and heat transfer are critical.

- Flexibility:

- Pipe: Rigid, requiring fittings for directional changes.

- Tube: Available in rigid and flexible forms, allowing for easier installation in confined spaces.

- Wall Thickness:

- Pipe: Classified by “types” (K, L, M) based on wall thickness.

- Tube: Defined by gauge or series, with thinner walls for precise flow control.

- Thermal Applications:

- Pipe: Less commonly used in heat transfer applications due to its thicker walls.

- Tube: Superior for thermal applications, such as HVAC or heat exchangers.

Choosing the Right Option for Your Needs

Selecting between copper pipe and copper tube depends on the specific requirements of your project.

- For Plumbing Systems: Copper pipes are ideal because they are designed to handle high water pressure, resist corrosion, and conform to standard plumbing codes.

- For HVAC and Heat Exchangers: Copper tubes are better suited due to their precise sizing, flexibility, and superior thermal conductivity.

- For Industrial Applications: Copper tubes often outperform pipes in systems requiring precision, such as medical gas lines or refrigeration.

Advantages of Copper Material

Regardless of whether you choose copper pipes or tubes, both offer key advantages:

- Durability: Resistant to corrosion and long-lasting.

- Thermal Conductivity: Efficient for heat transfer in HVAC and industrial systems.

- Recyclability: Environmentally friendly and sustainable.

- Antimicrobial Properties: Ideal for medical and potable water applications.

Insights into Modern Trends

Copper tubes are increasingly preferred in energy-efficient systems, particularly in modern HVAC applications. Innovations such as micro-groove copper tubes are revolutionizing heat transfer, enabling smaller, more efficient designs. Meanwhile, copper pipes remain the standard for plumbing due to their proven reliability over decades.

Common Misconceptions

One common misconception is that copper pipe and copper tube are interchangeable. While they share similar materials, their applications and design considerations are distinct. Choosing the wrong option can lead to inefficiencies, leaks, or system failures.

Final Thoughts

Understanding the difference between copper pipe and copper tube is essential for making informed decisions in plumbing, HVAC, or industrial projects.

Copper pipes are measured by internal diameter and are best suited for plumbing applications, while copper tubes are measured by external diameter and excel in precision systems like HVAC and heat exchangers. By selecting the right product for your specific needs, you can optimize performance, durability, and cost-effectiveness.

Whether you’re working on a residential project or an industrial installation, knowing when to use copper pipe versus copper tube can make all the difference in achieving reliable and efficient results. By understanding these distinctions, you’ll ensure your systems operate at peak performance for years to come.