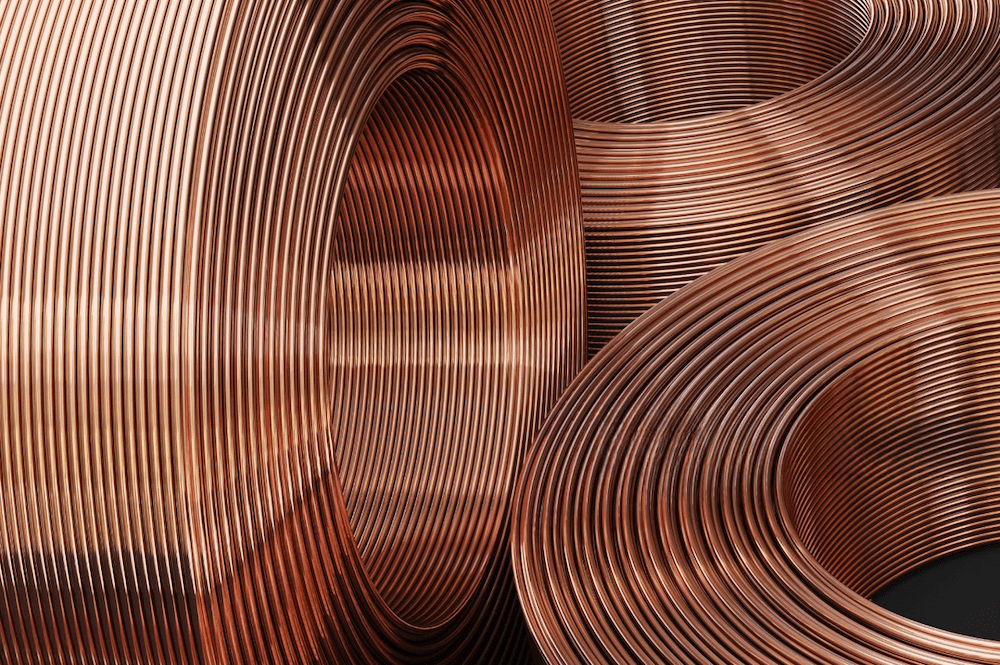

Flexible copper tubing is a versatile and durable material used across various industries, including plumbing, HVAC, refrigeration, and gas delivery systems. Its unique properties make it an essential choice for applications where rigid tubing falls short. But what exactly makes flexible copper tubing so advantageous? In this article, we’ll explore the primary benefits of flexible copper tubing, its applications, and why it stands out among other materials.

The main advantage of flexible copper tubing is its ability to bend and conform to tight spaces without compromising durability, allowing for easier installation, reduced need for fittings, and minimized risk of leaks. This makes it a versatile and efficient solution for challenging environments.

What Is Flexible Copper Tubing?

Flexible copper tubing is annealed during manufacturing, a process that softens the material, making it pliable while retaining copper’s inherent strength and resistance to corrosion. This flexibility allows it to bend easily without cracking, unlike rigid copper tubing.

Main Advantages of Flexible Copper Tubing

1. Ease of Installation

Flexible copper tubing simplifies the installation process by eliminating the need for multiple fittings:

- Fewer Joints: The tubing can be bent to navigate corners, walls, or obstacles, reducing the need for elbows and connectors.

- Quick Adjustments: Installers can easily shape the tubing on-site, saving time and labor costs.

2. Leak Reduction

Fewer joints mean fewer potential leak points:

- Enhanced Reliability: With fewer fittings required, flexible copper tubing minimizes the risk of leaks, making it ideal for systems that need long-term reliability.

- Lower Maintenance: Reduced joint connections translate to less frequent inspections and repairs.

3. Versatility in Tight Spaces

Flexible copper tubing excels in areas where rigid tubing cannot fit:

- Compact Installations: It can be routed through confined spaces, such as walls, ceilings, or narrow pathways.

- Ideal for Retrofits: Its pliability makes it perfect for upgrading older systems without extensive structural modifications.

4. Durability and Longevity

Despite its flexibility, copper retains its durability:

- Corrosion Resistance: Copper naturally resists corrosion, ensuring long service life even in humid or chemically active environments.

- Pressure Tolerance: Flexible copper tubing can handle significant pressure fluctuations, making it suitable for gas and water lines.

5. Compatibility with Diverse Applications

Flexible copper tubing is versatile and used across multiple industries:

- Plumbing: Ideal for potable water systems, as copper is non-toxic and antimicrobial.

- HVAC Systems: Used in refrigerant lines to connect components in air conditioning and refrigeration systems.

- Gas Distribution: Approved for transporting natural gas and propane in residential and commercial settings.

Comparison: Flexible Copper Tubing vs. Rigid Copper Tubing

| Feature | Flexible Copper Tubing | Rigid Copper Tubing |

|---|---|---|

| Flexibility | Highly flexible, easy to bend | Rigid, requires fittings for bends |

| Installation | Simple, fewer fittings needed | Complex, more fittings required |

| Applications | Tight spaces, retrofits, compact systems | Straight runs, structural support |

| Durability | Corrosion-resistant, durable | Highly durable, slightly stronger |

| Cost | Slightly higher initial cost | Lower material cost but higher labor |

Specific Applications of Flexible Copper Tubing

1. Residential Plumbing

Flexible copper tubing is commonly used in water supply lines, particularly in tight spaces under sinks, within walls, or around obstacles.

2. HVAC and Refrigeration

Its pliability makes it ideal for refrigerant lines, allowing seamless connection between compressors, condensers, and evaporators without excess fittings.

3. Gas Lines

Flexible copper tubing is approved in many regions for natural gas and propane lines, especially in installations requiring numerous directional changes.

4. Solar Heating Systems

Copper’s thermal conductivity, combined with its flexibility, makes it a preferred choice for transporting heated water or fluids in solar water heating systems.

Maintenance Tips for Flexible Copper Tubing

- Avoid Over-Bending: Excessive bending can weaken the tubing or cause kinks. Use a tubing bender to ensure smooth curves.

- Protect Against Physical Damage: Shield the tubing from impacts or sharp objects that could dent or puncture it.

- Inspect Connections: Periodically check for leaks or corrosion at fittings and joints.

- Use Proper Insulation: Protect the tubing from temperature fluctuations or freezing in colder climates.

Unique Insights: Why Flexible Copper Tubing Stands Out

Flexible copper tubing is not just a practical choice; it’s also an environmentally friendly material. Copper is 100% recyclable without losing its properties, making it a sustainable option for modern infrastructure. Additionally, copper’s antimicrobial properties provide an added layer of safety for potable water systems, ensuring clean and safe water delivery.

Challenges and How to Overcome Them

While flexible copper tubing offers significant advantages, it does have a few limitations:

- Higher Material Cost: Flexible copper tubing may be more expensive than rigid tubing. However, the reduced labor and installation costs often offset this.

- Kinking Risk: If improperly handled, the tubing can kink, reducing flow efficiency. Using a tubing bender or proper handling techniques prevents this issue.

Final Thoughts

Flexible copper tubing is a versatile and efficient solution for a wide range of applications, from residential plumbing to industrial HVAC systems.

The main advantage of flexible copper tubing is its ability to bend and conform to tight spaces, enabling easier installation, reduced fittings, and fewer leak points. This makes it a reliable and cost-effective choice for modern systems.

Whether you’re a contractor working on a large project or a DIY enthusiast tackling home improvements, flexible copper tubing offers unparalleled flexibility, durability, and efficiency. With proper installation and maintenance, it ensures long-lasting performance, making it a valuable asset for any system.