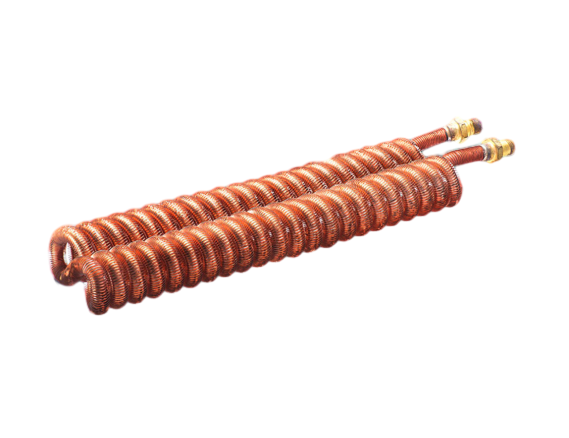

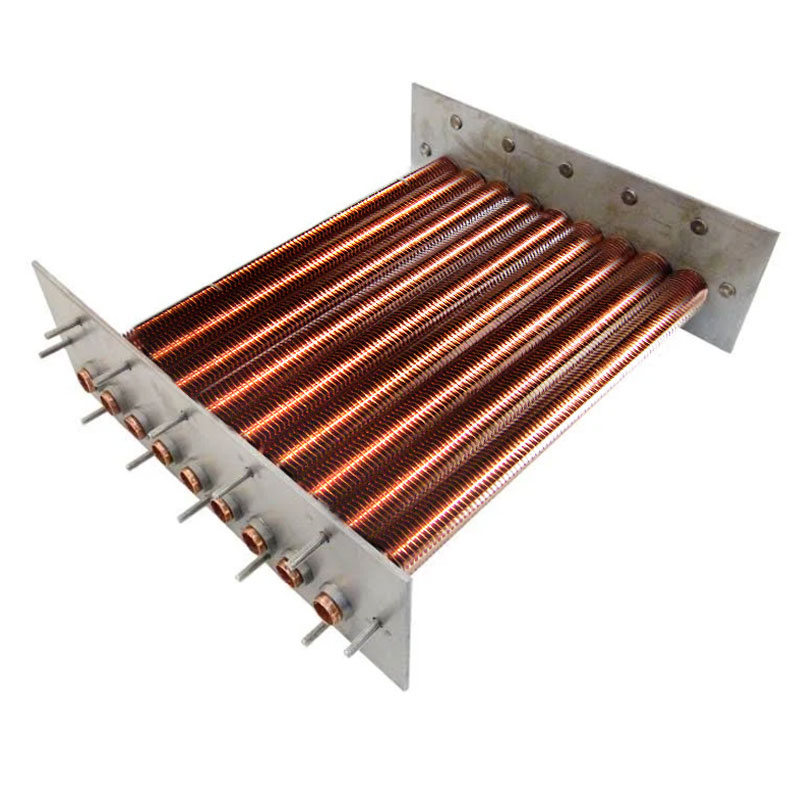

Heaters in various applications—from home heating systems and HVAC units to industrial boilers—often rely on finned tubes to improve performance. Finned tubes are specifically designed with small fins around a central tube, which significantly increases the surface area for heat exchange. This unique design makes finned tubes ideal for systems that require efficient heat transfer in a compact space. In this guide, we’ll dive into exactly why heaters use finned tubes, exploring their role in enhancing heat transfer, energy efficiency, and overall heating performance.

“Finned tubes increase the surface area available for heat transfer, making heaters more effective by enabling faster and more efficient heating in a compact design.” Understanding why heaters use finned tubes can help in choosing the best components for any heating system.

How Do Finned Tubes Improve Heat Transfer in Heaters?

At the core of every heater is the need to efficiently transfer heat from a heat source to the surrounding air. In heaters, finned tubes serve to maximize the surface area exposed to air without requiring additional space, making them highly effective for heat transfer.

The Importance of Surface Area in Heat Transfer

In any heating system, the rate of heat transfer depends largely on the surface area between the heating element and the surrounding environment. By increasing this surface area, heat can spread out and transfer more efficiently from the heater to the air. The fins on a finned tube essentially “multiply” the area that the heat can reach, enabling the heater to transfer heat at a much faster rate than it would with a smooth, unfinned tube.

- More Surface, More Heat Transfer: The fins significantly expand the tube’s surface area, allowing more heat to be exchanged between the heated tube and the air around it.

- Accelerates Heating Response: With more surface area, finned tubes allow heaters to heat up or cool down more quickly, responding efficiently to temperature demands.

The basic principle of heat transfer—that more surface area means more efficient heat exchange—is the primary reason why finned tubes are widely used in heaters.

Key Reasons Heaters Use Finned Tubes

Let’s explore in detail why finned tubes are so effective in heating systems and why they are preferred over smooth, unfinned tubes.

1. Enhanced Heat Transfer Efficiency

The most compelling reason heaters use finned tubes is that they enhance heat transfer efficiency. Adding fins to a tube increases the area available for heat exchange, which allows for better heat dissipation or absorption.

- Rapid Temperature Control: With their larger surface area, finned tubes can transfer heat more effectively, helping heaters to quickly reach and maintain the desired temperature.

- Ideal for Systems with High Heat Requirements: In systems that need to quickly transfer large amounts of heat, such as industrial boilers or HVAC units, finned tubes make it possible to achieve high-performance heating without requiring larger, more complex equipment.

For applications where quick and efficient heat transfer is crucial, finned tubes are an optimal choice because they can reach the target temperature faster and maintain it more effectively than smooth tubes.

2. Energy Efficiency and Cost Savings

Finned tubes also help reduce energy consumption by making heat transfer more efficient, which can lead to significant savings in operational costs over time.

- Reduced Energy Demand: Since finned tubes enhance heat transfer, they allow heaters to achieve the desired temperature more quickly. This efficiency reduces the energy needed to run the heater, leading to lower energy consumption.

- Long-Term Cost Savings: With finned tubes, heating systems operate more efficiently, which translates into lower electricity or fuel costs. This makes them a cost-effective solution in applications where heating is required frequently, such as in commercial or industrial facilities.

By optimizing the efficiency of heat transfer, finned tubes help heaters run with less energy, reducing operational costs and contributing to more sustainable energy use.

3. Compact Design for Space Efficiency

Finned tubes enable compact heating systems without compromising on heat transfer performance. This advantage is especially important in applications where space is limited.

- Powerful Heating in Small Spaces: Finned tubes allow for powerful heat transfer in a smaller footprint, making them ideal for use in confined spaces like homes, offices, and vehicles.

- Ideal for Portable Heating Solutions: In portable heaters and HVAC systems, space is often limited, and efficiency is a priority. Finned tubes allow for compact designs that still deliver high heating performance, perfect for portable heaters, baseboard heating, and residential HVAC units.

With finned tubes, heating systems can be designed to be more compact while still delivering high levels of efficiency, making them a practical choice for both residential and commercial heating needs.

4. Even and Consistent Heat Distribution

Another reason why heaters use finned tubes is that they help create even heat distribution. In heating applications, consistent heat distribution is crucial to maintaining comfort and effectiveness.

- Eliminates Hot and Cold Spots: In a heater without finned tubes, temperature distribution can be uneven, creating hot and cold spots in the area being heated. Finned tubes improve airflow and heat dispersion, leading to a more even temperature distribution.

- Better Thermal Comfort: In residential and commercial spaces, consistent heat improves thermal comfort by preventing sudden temperature changes or uncomfortable hot zones.

This even distribution is critical in HVAC systems and room heaters, where maintaining a steady and uniform temperature is essential for comfort and efficiency.

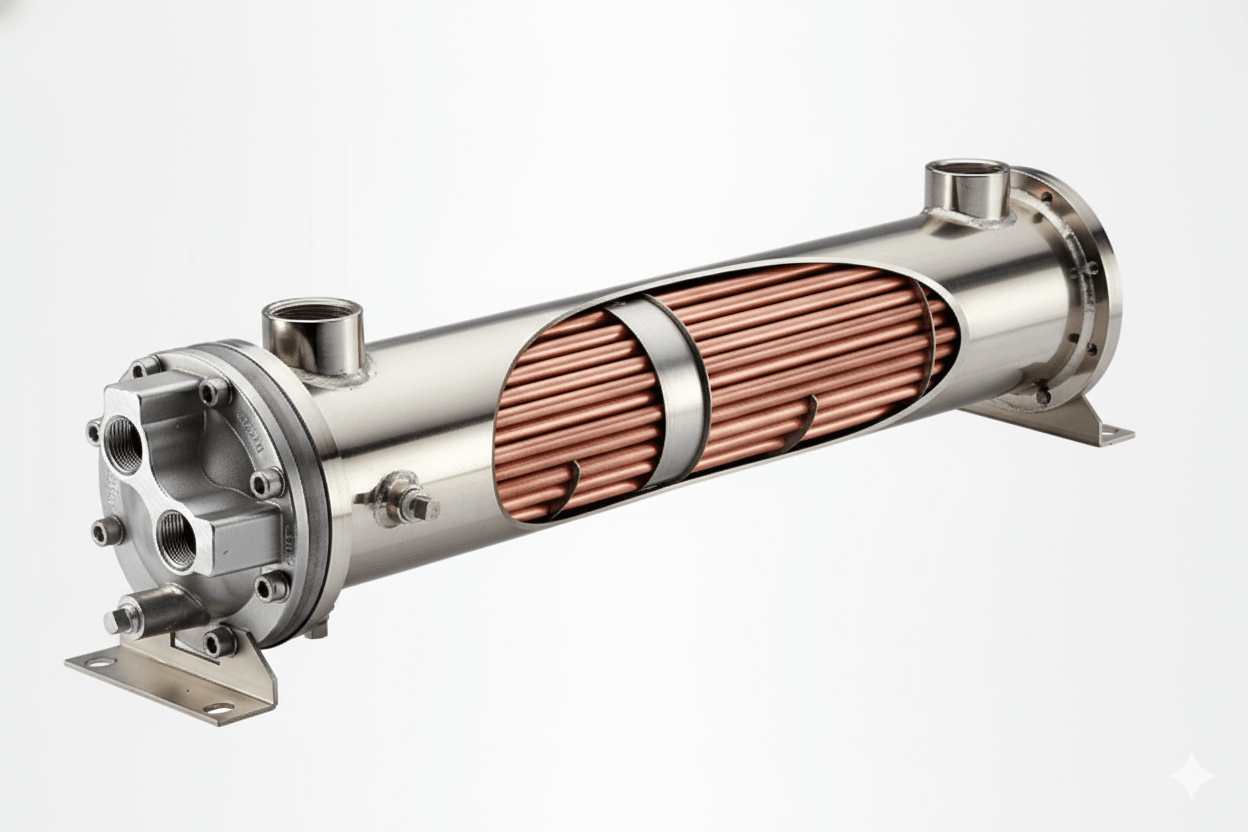

5. Versatility Across Different Heating Applications

Finned tubes are versatile components that can be used in a wide variety of heating systems, making them a preferred choice across industries and applications.

- Adaptable to Different Heat Sources: Finned tubes work with various heat sources, including electric, gas, and fluid-based heating, giving them broad applicability.

- Widely Used Across Industries: Whether it’s residential heating, commercial HVAC, or industrial applications, finned tubes are adaptable and effective. Their versatility means they can be customized for specific requirements, such as in chemical processing, automotive heating, and power generation.

This adaptability makes finned tubes a practical and efficient choice in any heating application that requires effective and consistent heat transfer.

Potential Drawbacks of Using Finned Tubes in Heaters

While finned tubes offer many benefits, they also have some limitations. Understanding these can help determine whether finned tubes are suitable for a particular heating system.

1. Dust and Dirt Buildup

One drawback of finned tubes is their susceptibility to dust and dirt accumulation, which can reduce heat transfer efficiency over time.

- Reduced Efficiency Due to Dust: The fins can collect dust, dirt, and debris, which insulates the fins and reduces their effectiveness. This is particularly problematic in environments where air filtration is minimal or where there is high airborne dust.

- Requires Regular Maintenance: To maintain optimal performance, finned tubes require periodic cleaning to prevent dust buildup. This can add to maintenance costs and effort, especially in dusty or unfiltered environments.

In settings where airflow contains high levels of dust or contaminants, finned tubes may need frequent cleaning to ensure consistent performance.

2. Potential Airflow Resistance

The fins on finned tubes can create a minor resistance to airflow, which may impact system performance in certain applications.

- Increased Airflow Resistance: While fins increase surface area, they can also obstruct airflow slightly, requiring stronger fans or blowers to maintain adequate circulation.

- Impact on Efficiency in Certain Applications: In ventilation or high-efficiency HVAC systems, where smooth airflow is essential, the resistance created by finned tubes might reduce overall system efficiency.

For systems where airflow must be unrestricted, such as in certain ventilation setups, finned tubes may introduce resistance that needs to be managed.

Conclusion: Why Finned Tubes are Essential in Heaters

Finned tubes are an effective and practical solution in heating systems due to their ability to enhance heat transfer efficiency, improve energy savings, support compact designs, and promote even heat distribution. While they require regular maintenance and may create slight airflow resistance, these factors are generally outweighed by their benefits.

Summary: Finned tubes maximize surface area, enabling heaters to transfer heat efficiently in compact spaces. This allows for faster heating, energy savings, and consistent temperature distribution. With regular maintenance, finned tubes can enhance the performance and efficiency of a wide range of heating systems.

Finned tubes are a versatile and valuable component, ensuring heaters operate effectively across various applications, from residential to industrial settings. Their role in optimizing heat transfer makes them an essential choice for efficient and reliable heating solutions.